Welding Aluminium Alloy Journals

Potentials and Problems in Aluminium Welding. Metzbower Laser beam welding of aluminum alloy 5456 Weld.

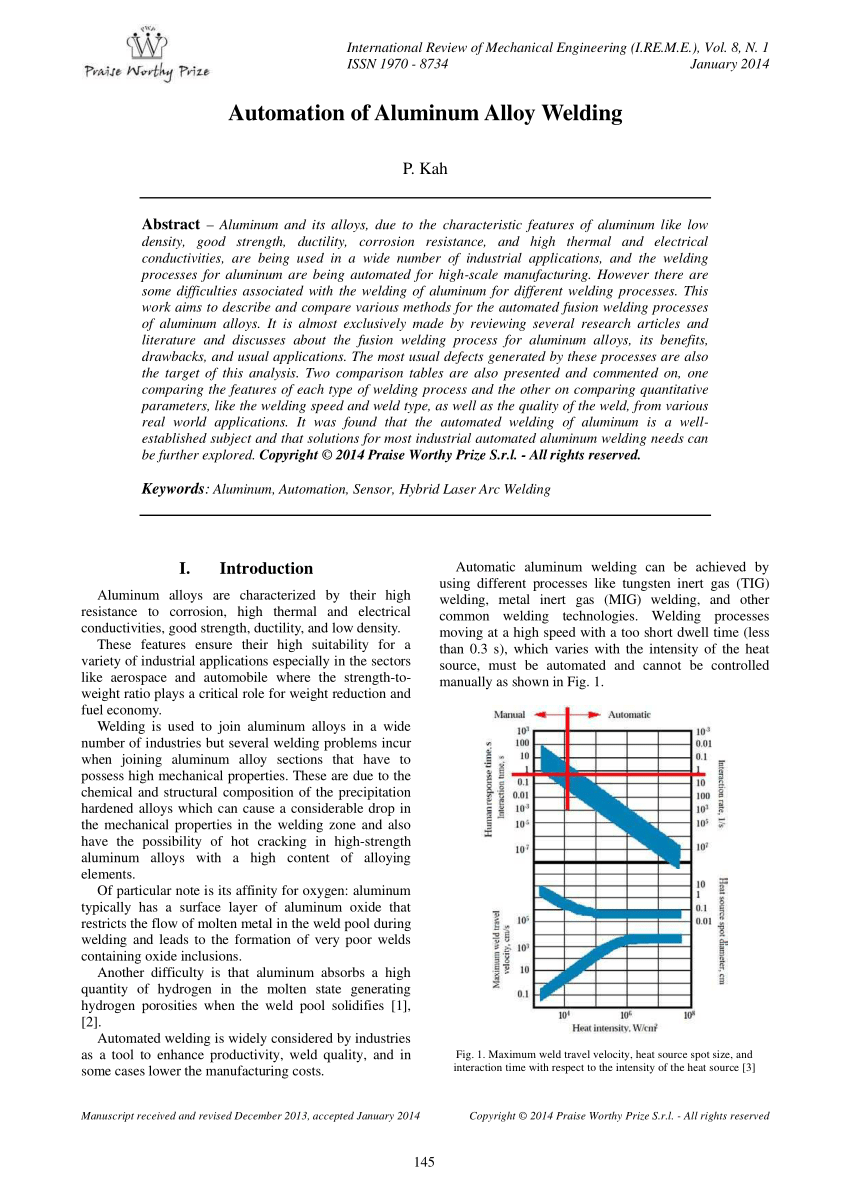

Pdf Automation Of Aluminum Alloy Welding

A study on dissimilar welding of aluminum alloy and advanced high strength steel by spot welding process.

Welding aluminium alloy journals. Ad Find China Manufacturers Of Aluminum Welding. 2016 IJSRSET Volume 2 Issue 3 Print ISSN. 2395-1990 Online ISSN.

A rundown on these four alloys including properties. The Welding of Aluminium and its Alloys is a practical users guide to all aspects of welding aluminium and aluminium alloys. Effect of Thermal Cycling on Friction Stir Welds of 2195 Aluminum AlloyWelding Journal Miami Fla 2001 8037179.

These two metals characterize Aluminium alloys on the one side and steels on the. Contact our experts now. World Journal of Engineering and Technology 6 296-303.

Nickel Alloy Electrodes supplier stockist. It provides a basic understanding of the metallurgical principles involved showing how alloys achieve their strength and how the process of welding. However it should be noted that the thickness of the intermetallic phases in the friction welded AlMg3 aluminium alloy-X10CrNiTi189 austenitic steel joints was significantly lower about 13 μm than the one occurring in the diffusion welding 68 μm 29 30.

Miami 62 53s 58s 1983. These are aluminum-silicon-magnesium AlSiMg alloys but some 3190 for example also contain copper Cu. Table 1 compares typical properties of Aluminium and Iron.

Low-temperature Friction-stir Welding of 2024 AluminumScripta Materialia 1999 41 8809815. Article CAS Google Scholar 11. Oertelt G Babu S S David S Aet al.

Ad We supply Inconel 625 600 825 welding electrode filler wire. 2015 Joining steel to aluminum alloy by resistance spot welding with a rivet. The good news is that these alloys are all readily weldable with 4043 serving as the correct filler.

For this reason the friction welded AlMg3 aluminium alloy-X10CrNiTi189 austenitic steel joint can successfully replace the joints formed with. Benavides S Li Y Murr L Eet al. Ad Find China Manufacturers Of Aluminum Welding.

Engineering and Technology A Comparison of Welding Techniques of Aluminium Alloys A Literature Review Ajay Kumar Mohammad Shahal Milton Department of Mechanical Engineering LRIET Solan Himachal Pradesh India ABSTRACT Welding of aluminum alloys is an important issue. 7010 and 7050 and most of the 2xxx series are not recommended for fusion welding because they are prone to liquation and solidification cracking. The fact that business is good in aluminum welding is a sure sign that more manufacturers and fabricators are using GMA and GTA welding to build new products out of this lightweight nonferrous metal.

Among the most widely specified weldable grades are Alloys 6061 5083 5052 and 5454. The joints of the aluminium alloy 2219 have significantly reduced their welding strength and increased the welding deformation. We ship worldwideCall us.

Nickel Alloy Electrodes supplier stockist. The most common aluminum casting alloys are the heat-treatable 3XX0 series such as 3560 3570 and 3190. We ship worldwideCall us.

High strength alloys eg. Contact our experts now. Ad We supply Inconel 625 600 825 welding electrode filler wire.

Stocks in huge qty. Butt-welding of an aluminium alloy plate to a steel plate was easily and successfully achieved by friction stir welding. International Journal of Materials Research 106 1 60-65.

The technique of Friction Stir Welding is particularly suited to aluminium alloys. Qiu R Wang N Shi H Cui L Hou L. Mazumder Control of magnesium loss during laser welding of Al-5083 using a plasma suppression technique Journal of Engineering for Industry 107 275 280 1983.

To address these constraints several researchers have developed AC TIG soldering VPTIG welding and plasma solving variable polar. The 5xxx series alloys in particular have excellent weldability. For example when arc welding aluminium alloys weld metal porosity and depending on the particular alloy weld metal solidification cracking and HAZ liquation cracking are among the most common flaw types.

The maximum tensile strength of the joint was about 86 of. 2018 Challenges in Thermal Welding of Aluminium Alloys. Stocks in huge qty.

The occurrence of such problems has contributed to the widely held view that some aluminium alloys in particular some of the high strength 2xxx and 7xxx series alloys are difficult or indeed impossible to fusion weld.

Pdf Mechanical Properties Of Aluminum 6063 Alloy Joined By Tungsten Inert Gas Welding And Friction Stir Welding Methods

Pdf Metallurgical And Mechanical Properties Of Heat Treatable Aluminum Alloy Aa6082 Welds

Pdf Effect Of Welding Parameters On Microstructure And Mechanical Properties Of Aa7075 Aa5182 Alloys Joined By Tig And Mig Welding Methods

Pdf Feasibility Of Using Tig Welding In Dissimilar Metals Between Steel Aluminum Alloy

Pdf Recent Developments In Friction Stir Welding Of Al Alloys

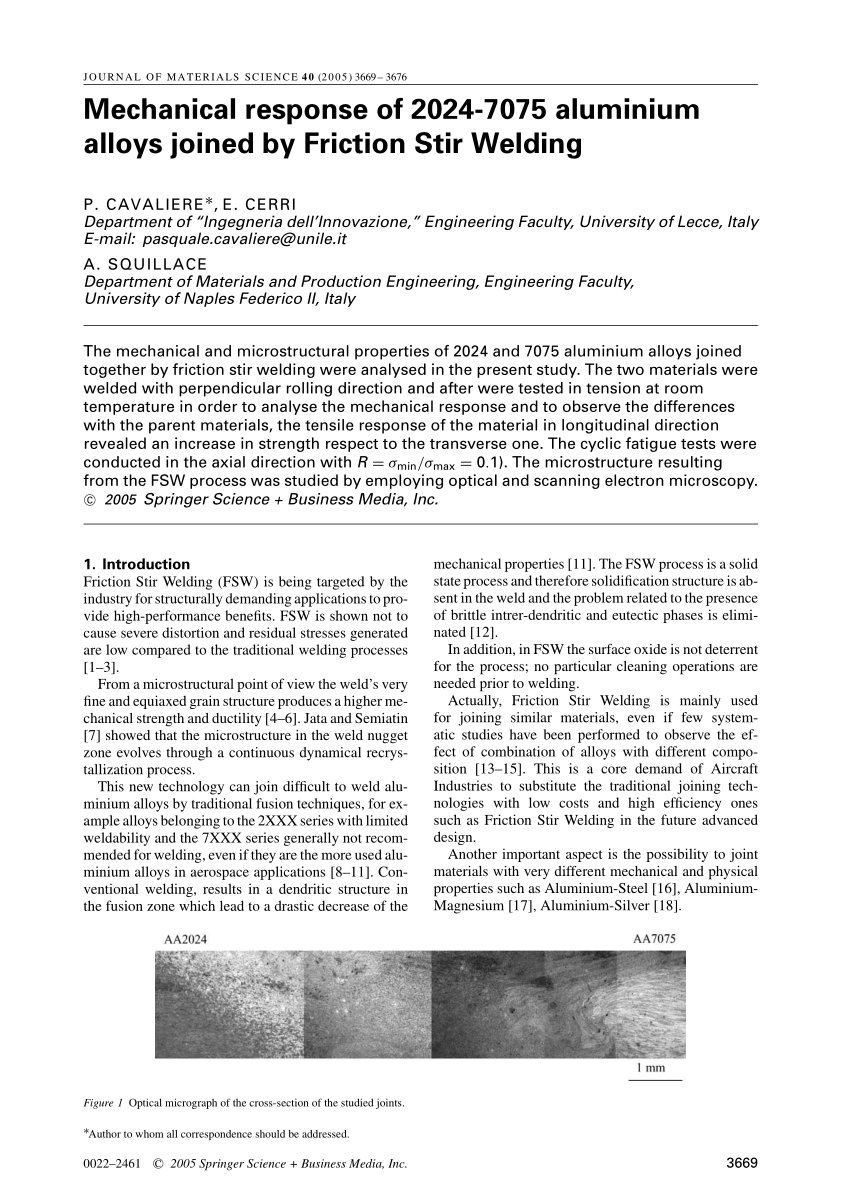

Pdf Mechanical Response Of 2024 7075 Aluminium Alloys Joined By Friction Stir Welding

Pdf Aluminium Alloys Welding Processes Challenges Joint Types And Process Selection

Pdf Microstructure And Mechanical Properties Of Aa 5083 And Aa 6061 Welds Joined With Alsi5 And Alsi12 Wires

Pdf Effect Of Filler On Weld Metal Structure Of Aa6061 Aluminum Alloy By Tungsten Inert Gas Welding

Post a Comment for "Welding Aluminium Alloy Journals"