Welding Aluminum Bronze To Carbon Steel

Hi all Anybody having experience in Aluminum Bronze - C63000 to carbon steel welding full penertration fillet weld if. It seems to work best as an electric brazing.

What Is Aluminum Bronze Used For Bronze Aluminum Oil And Gas

Class 3 is used for electrodes subjected to high pressures for heavy sections for stainless and other heat resistant alloys.

Welding aluminum bronze to carbon steel. Ad Find China Manufacturers Of Aluminum Welding. 33 The bonding strength of aluminium bronze al loy and ASTM 1045 steel. Class 1 is used for welding coated carbon steel aluminum and magnesium.

Stainless Steel Carbon or Carbon or Low Alloy Steel Low Alloy Steel Weld Metal Buttering Layer of Pure Ni Copper Steel Electrode Copper Carbon or Low Alloy Steel Joint Parts Material Thermal ExpCont Coeff. Carbon steel stainless steel aluminum magnesium copper nickel silicon bronze. Aluminum bronze is a type of bronze in which aluminum is the main alloying metal added to copper and is typically made up of 9 to 12 aluminum and up to 6 iron and nickel.

Theyre thick enough that you can use a regular GMAW or GTAW technique and weld the steel side to steel and the aluminum side to aluminum. With that in mind lets take a closer look at which metals can be welded what it takes to weld them and a few tips and tricks to help you master metal welding. Aluminum bronze welding can take place using the MIG welding technique with an aluminum bronze.

Ive used 035 GMAW Silicon Bronze 100 argon shielded on chromed shopping carts modular shelving aluminum irrigation pipe low to medium high carbon steel all with excellent results. Ad Find China Manufacturers Of Aluminum Welding. Coat the steel prior to welding.

1K x 10-6 YS ksi UTS ksi Stainless Steel 316 L 19 42 84 Weld Metal 308 L 19 29 84 Buttering 309 L 19 40 95. Aluminum bronze can work even better for wear areas. But because of its low melt point silicon bronze tig brazing works better on galvanized sheet than welding.

This simply means that prior to welding the steel and aluminum together the steel is first coated in aluminum. Anybody having experience in Aluminum Bronze - C63000 to carbon steel welding full penertration fillet weld if so please share following details. Strength of Sample 1.

Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal. Aluminum bronze alloys AMPCO-TRODE 7 10 150 160 are recommended for welding aluminum bronze of similar composition and for surfacing for bearing surfaces on steel for metal to metal wear. Class 2 is used for low carbon steel stainless steel and silicon bronze.

These inserts are pre-bonded usually by using a hot rolling or hot pressure welding technique explosion welding. CONSULTANT-WELDING QUALITY. The following metals can be MIG welded.

Use of a buffer layer on carbon steel either Cu-Ni 7030 or 9010 followed by welding. Aluminum bronze C63000 is a Copper-Aluminum alloy. Weld aluminum tubing with steel or stainless steel tube sheets on heat exchangers.

Two alloys that are well suited for dissimilar metal welding are WWW-A2 BRONZE WELD aluminum bronze AWS A57ER CuAl-A2 and WWW SIL-WELD silicon bronze AWS A57ER CuSi-A. The average test results of bonding strength of different samples are shown in Figure 7. These alloys produce a deposit with an average.

When the higher heat used with other welding rods is used on galvanized the zinc boils and out gasses. WWW PHOS-C-WELD and WWW COPP-WELD can also be used for certain dissimilar metal combinations but they are not as versatile as either the silicon- or aluminum bronze alloys. It can be used on sheet metal gauged stainless steel but only with fast travel speed and minimal heat input.

Next start your torch or welder bring it close to the metal without touching it and move it around so the metal. Its not directly weldable to Carbon steel. ERNi-1 could also be used.

Another method many use to successfully weld aluminum to steel is dip coating also commonly referred to as hot dip aluminizing. Type of filler wire - GTAW. Produce arc-welded joints between aluminum and steel pipelines.

ERCuAl-2 is recommended for welding aluminum bronze and 90Cu10Ni to carbon steel. Then use a degreasing solution to clean the metal surfaces youre welding and coat the weld spot with flux. Before you weld bronze put on gloves a mask and a welding suit for protection.

Due To Its Ductility And Electrical And Thermal Conductivity Copper Is Oftentimes Used In The Production Of El Copper Electrical Conductor Stainless Steel Rod

Welding Consumables Welding Consumables Welding Mag Welding

Brazing Rods Manufacturers Suppliers In India For Copper Aluminum

Basic Welding Welding Welding And Fabrication Stainless Steel Scrap

Pin By Steel House India On Https Www Steelhouseindia Com Stainless Steel Bar Stainless Steel Rod Round Bar

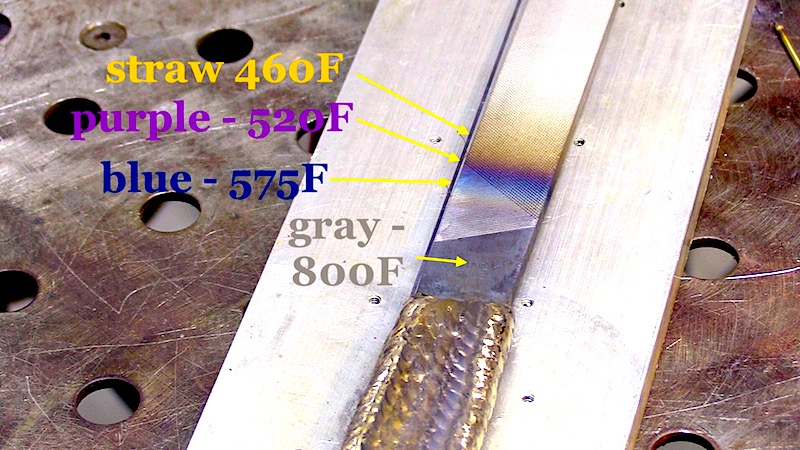

How To Tig Braze A Knife Handle

How To Tig Braze A Knife Handle

Pin By Steel House India On Https Www Steelhouseindia Com Stainless Steel Bar Stainless Steel Rod Round Bar

World Wide Metric S Tubing Selection Includes Carbon Steel Stainless Steel Copper Copper Nickel And Aluminum Brass Copper Copper Tubing Cylinder

Post a Comment for "Welding Aluminum Bronze To Carbon Steel"