Gas Welding Stainless Steel Tubing

For double-welded tubing multiply working pressure by 085 for single-welded tubing multiply working pressure by 080. The inside surface of a completed weld on properly purged stainless-steel pipe will be smooth even and uniform.

Awesome Tig Welding Welding Metal Welding

Weld Fittings Caps Necks and Pickup Tubes IN-STOCK Ready to Ship.

Gas welding stainless steel tubing. Ad Find China Manufacturers Of Welding Wire. Even though most of the welding machine manufacturers have included a table of materials and voltage settings in the machine it is highly important for you to pick the right kind of gas and electrode wire to be used for MIG welding stainless steel. Welded tubing can be accomplished either by hot forming and cold forming processes.

The thin-walled stainless steel tubing generally means. Ad Find China Manufacturers Of Welding Wire. Copper tubing can be used to make tools for gas shielding alsoJust get some pieces of 14 copper tubing and drill a straight line of holes every 14 or so using a 116 drill bit.

Crimp one end with a vise or pliers or just crimp and weld it shut. Shielding gas selection for wire processes is more complicated. The variation in weld penetration was attributed primarily to differences in sulphur and to a lesser extent oxygen content in broad agreement with a published model for such effects based on surface.

This is the gas that will duly protect our work from all sorts of atmospheric contamination. GMAW In the GMAW process also known as to MIG Metal Inert Gas process the welding heat is produced by an arc struck between a continuously fed metal wire electrode and the workpiece. Of the two cold forming results in.

Besides if youre planning to MIG weld stainless steel the best shielding gas you can use would be 25 of carbon dioxide 75 argon with a 90 helium combination. Thin tube and thin tube welding thin tube and thick tube welding including tube cross welding and concentric welding the most difficult to weld problem is easy to burn through collapse for which must take certain technological. Higher carbon ferritic stainless steels eg 430 434 442 and 446.

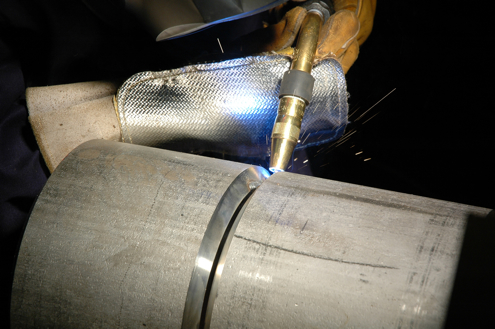

The pipe diameter is φ5 to 50 mm and the wall thickness is δ03 to 10 mm. When you make stainless tanks gas diesel water septic you always end up with corner joints welded on the outside. THE WELDING OF STAINLESS STEELS 6 212 Processes with a Fusible Electrode 2121 Gas Metal Arc Welding.

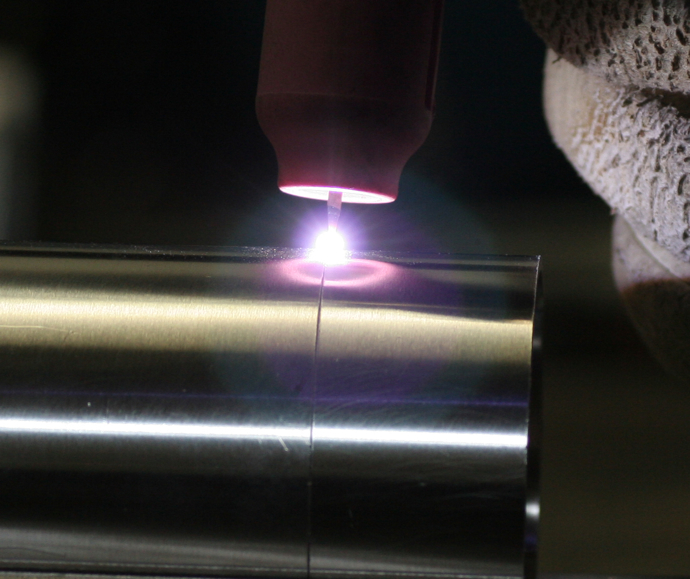

Suggested Allowable Working Pressure for Stainless Steel Tubing. During GTA welding of stainless steel tubing a program was undertaken to identify the cause of the problem and to develop remedial techniques. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

32 MARTENSITIC STAINLESS STEELS The martensitic stainless steels contain 11 to 18 Cr up to 120 C and small amounts of Mn and Ni. With a gas flow of 50 ft3min purge time can range from 30 seconds per foot of pipe for 3-inch pipe and smaller to 90 minutes per foot of 48-inch pipe. Many of the highly alloyed ferritic stainless steels are only available in sheet and tube forms and are usually welded by GTA without filler metal.

Alternative gases that you can use are 98 Argon and 2 Co2 or 98 argon and 2 oxygen mix. A welded stainless steel tube is produced through roll forming strips or sheets of stainless steel into a tube shape and then welding the seam longitudinally. The form of welded joints is.

This technique is of course usable on all kinds of tubing and dimensions not just one inch stainless steel tubing railings. Contrary to the GTAW and PAW processes. Tip for Tig Welding Stainless Steel Tanks.

For Welded Tubing For welded and drawn tubing a derating factor must be applied for weld integrity. Traditionally MIG welding has relied on mixtures of argon and carbon dioxide argon and oxygen and 3 gas mixtures based on helium argon and carbon dioxide. Straight argon is recommended for gas tungsten arc welding TIG of stainless steel tube and pipe.

Welding Stainless Steel Tube And Pipe Maintaining Corrosion Resistance And Increasing Productivity

Welding Faqs All You Need To Know About Exhaust Welding Burns Stainless

Welding Thin Stainless Steel Tube Why Gtaw Is The Method To Choose Arc Machines

Gas Welding Stainless Steel Part One Youtube

Stainless Steel Tubing Welding Tips

Welding Stainless Steel Weld Talk Message Boards

Welding Stainless Steel Tube And Pipe Maintaining Corrosion Resistance And Increasing Productivity

Welding Stainless Steel Tube And Pipe Maintaining Corrosion Resistance And Increasing Productivity

Post a Comment for "Gas Welding Stainless Steel Tubing"