Welding Galvanized Steel Decking

Welding of galvanized steel is done almost exactly the same way as welding of the bare steel of the same composition. However using the same washer type and the same welding rates with a thicker steel deck panel may severely limit heat available for penetration into the substrate.

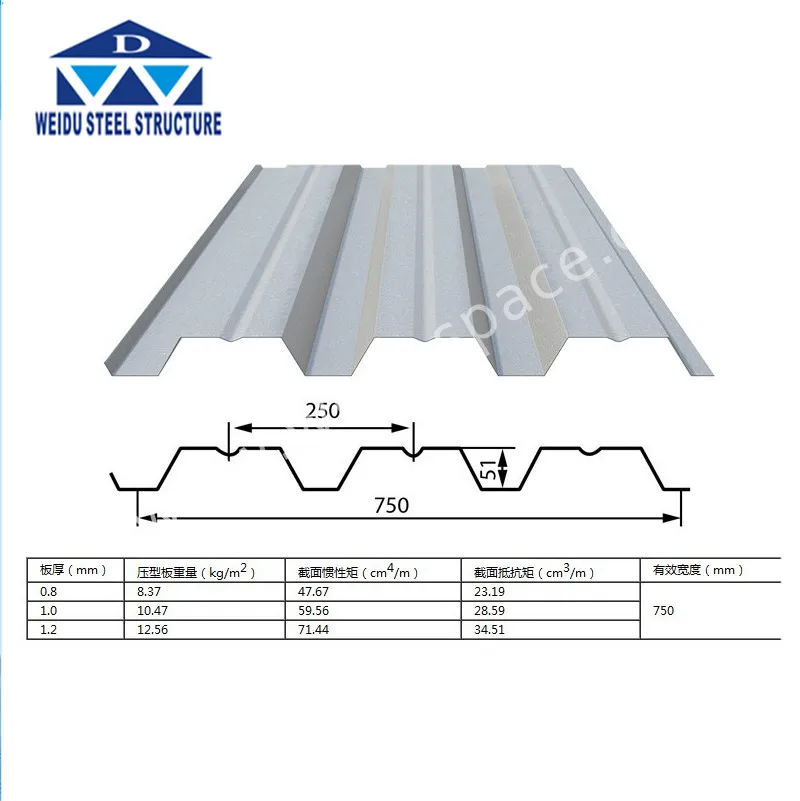

China Galvanized Bondek Metal Decking Panels Sheets For Highrise Buiding China Steel Deck Steel Floor Decking

Electric arc welding is the best and most economical method for attaching Wheeling steel roof deck to structural supports.

Welding galvanized steel decking. In the case of galvanized metal decking removing zinc from the area of the weld is impractical. However the practice of stud welding on galvanized steel remains very common. Removing the coating and re-spraying or painting the weld seam after welding to regain corrosion resistance.

Metal deck is often installed using arc spot welds either with or without weld washers. Strike an arc and begin welding. Do you weld on galvanized metals.

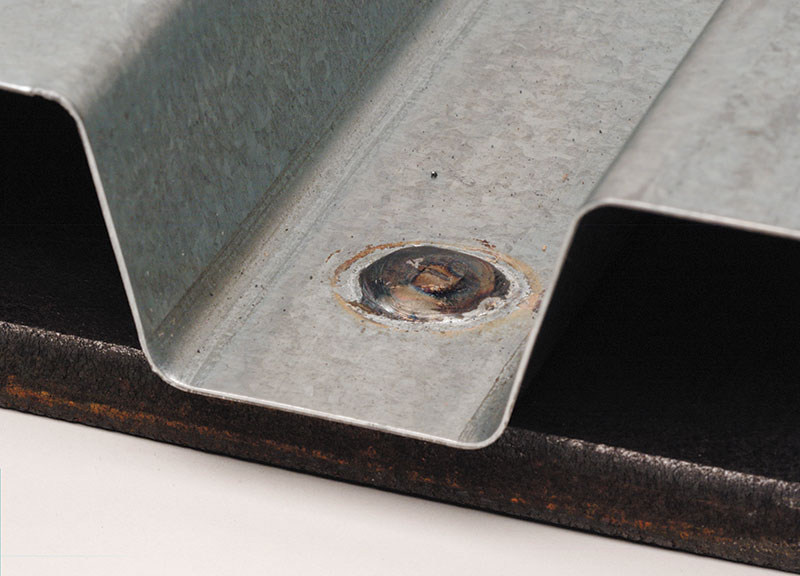

This is known to happen to large areas of galvanized decking after welding to steel joists. All welds are to be made from the top of the deck down through the bottom flange of the ribs. Diameter for arc spot welds or at least 38 in.

When metal deck is to be welded to supports the effective fusion area is at least 12 in. Use eye protection and a respirator when you spray the zinc around the weld and hold. If you are welding on galvanized steel decking it is important to wear a respirator or mask that is rated for galvanized zinc fumes or your lungs and other organs will be damaged.

Arc spot welds also referred to as puddle welds. The easiest way to add a coating to the bare steel is a galvanizing spray. However for through-deck welding of shear studs a modified welding.

Puddle welding deck to galvanized steel dik Structural 1 Aug 13 0922 kingnero. However for closed in areas ventilation must be provided. Long for arc seam welds.

Adequate ventilation is extremely important when welding galvanized metal decking. One of the most significant health hazards in the welding process is the generation of fumes and gasses. Used to attach floor and roof deck.

Work of stud welding safety netting etc. Pressed steel formwork for restraint of wet concrete at slab edges. Welding washers are recom-mended when welding metal thickness is less than 00280 inches.

Using a weld rod you burn through the decking into the steel beam below and make a puddle weld about the size of a nickel. The process of welding metal decking to the steel framing is done by using a welding machine and a weld rod. This adds two operations.

This migration generates a rusty orange appearance as the iron reacts with surface zinc oxides hydroxides etc producing an unsightly appearance with the ability to produce rust stains on items below. Number of decking sheets secured together with metal bands also called a pack. If galvanized steel is going to be welded without removing the coating its important to point out that the welding electrode composition should be checked to assure that the silicon content is very low because a high silicon content can cause zinc to penetrate the weld metal leading to cracking.

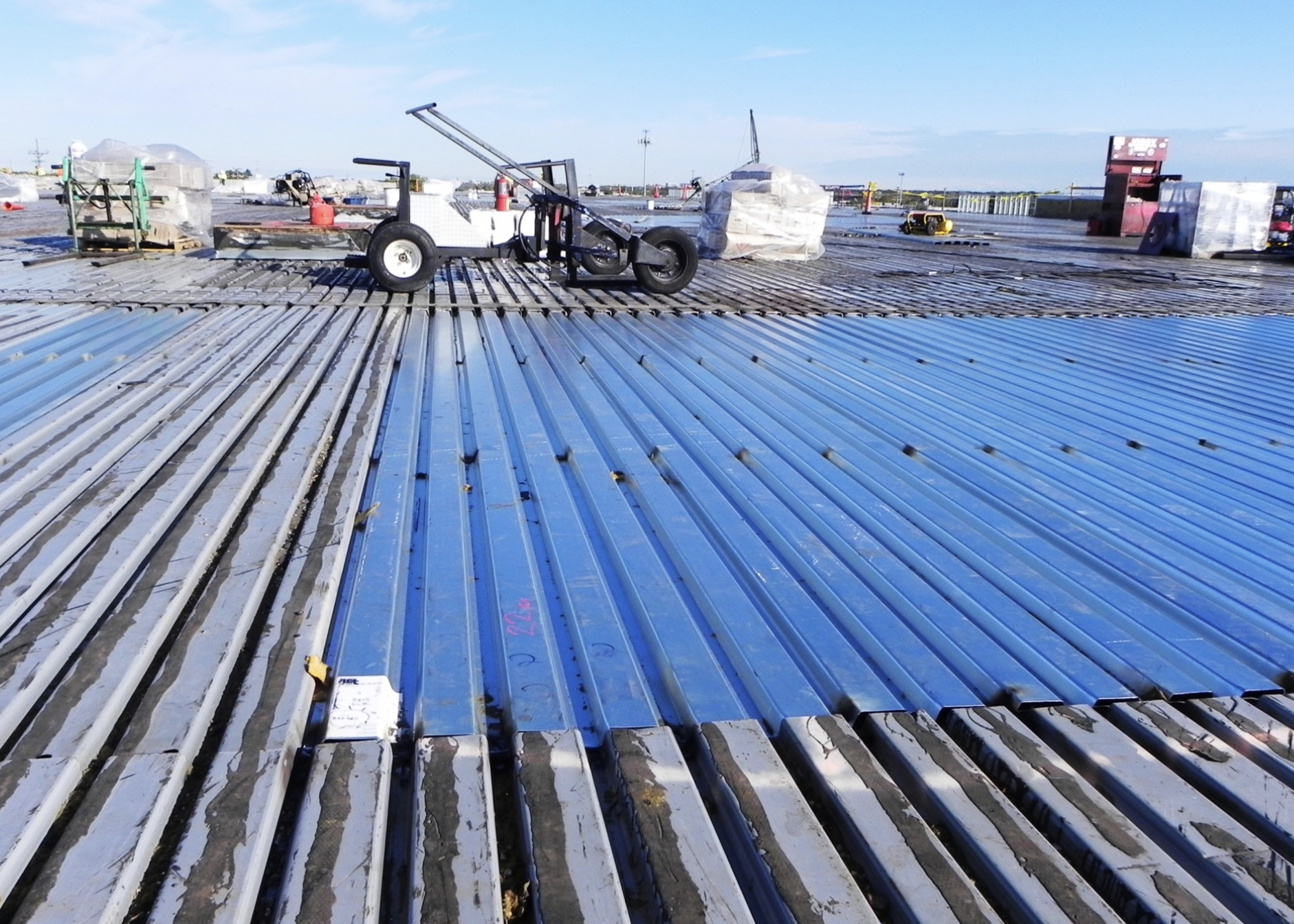

Welding On Galvanized Metals. Welder shall follow close to the placement crew. Galvanized deck must be used for those roof deck systems where form deck is used to.

The same welding processes volts amps travel speed etc. Pre-formed galvanized sheet steel to close gaps between. The best way to weld galvanized steel regardless of welding process is to remove the zinc coating from the joint.

All workers involved in the welding operation must wear eye protection to avoid weld flash. Form deck is furnished galvanized prime painted or uncoated. Galvanized decking is placed on top of the steel girder as part of the concrete form and it is general practice to weld through the galvanized decking to the base metal of the steel girder.

The presence of zinc and included zinc vapors in the weld can weaken the weld to the point of failure. The stud itself becomes part of the weld material. Can be used with little modification when the switch is made from uncoated steel to galvanized steel -- unless the zinc coating is unusually thick.

On bare uncoated steels this practice is viable and reliable means of welding. Puddle welds are similar to plug welds but for thin material They are used for light gauge material and are effected by burning a small hole through the deck with the fusion between the base material and the burned circumference of the puddle. Since most construction work is done in open air ventilation for welding is usually adequate.

Generally when welding to galvanized material zinc must therefore either be eliminated locally before welding or the galvanizing removed locally an expensive option or the galvanizing must be carried out after the studs are welded to the beam. The galvanized steel on a welded fence will rust if the welder does not reapply the zinc coating. For a particular application a five second welding time may be adequate to form a high quality weld through a weld washer into steel deck thicknesses between 0015 and 0028 inches.

For hot-dip galvanized steel the same process can be performed but the end results are somewhat different. Zinc is the coating used on galvanized metals and when you heat the metal it produces vaporized metal droplets which are. Put the welding rod into the welding electrode.

How To Make An Arc Spot or Metal Deck Puddle Weld. Individual panels of decking.

Frequently Asked Questions Faq Quality Metal Decking

Fireproof Corrugated Galvanized Metal Deck Floor Panels And Steel Sheet Flooring Decking For Concrete Suppliers China Low Price China Steel New Material

Frequently Asked Questions Faq Quality Metal Decking

Structure Magazine Arc Spot Welding Steel Deck A Primer

Structure Magazine Arc Spot Welding Steel Deck A Primer

Best Selling Metal Decking Steel Deck With Reinforced Steel Truss Steel Truss Decking Sheet Buy Steel Truss Decking Sheet Steel Deck With Reinforced Steel Truss Metal Decking Product On Alibaba Com

Replacing Structural Metal Deck In Re Roofing Applications Roofing

China Corrugated Metal Floor Decking Sheet Manufacturers Suppliers Factory Cost Price Famous

Post a Comment for "Welding Galvanized Steel Decking"