You obtain cubic inches and use the density of steel to calculate weight. Formula of Weld Volume.

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Select your weld preparation all variables are mandatories to proceed the calculation Th - Sheet thickness mm Steel density - 781 Carbon steel 790 Stainless steel Seam length m d1 - Groove depth mm G - Root gap mm - 0 1 2 3 4 5 6 7 8 9 10 c1 - Cap mm - 0 1 2 3 4 5 c2 - Cap mm.

How to calculate weld metal volume. There are several online calculators are also available. Determine Volume of welding mm To determine welding volume we must follow with below mandatory items. Flat1G1F PAHorizontal Horizontal-Vertical 2G2F PCPBVerticalUp 3G3F PFOverhead 4G4F PEPDPipe Fixed Horizontal5G PFPipe Inclined 45 6G HL045Vertical DownPG No data to be entered below this line.

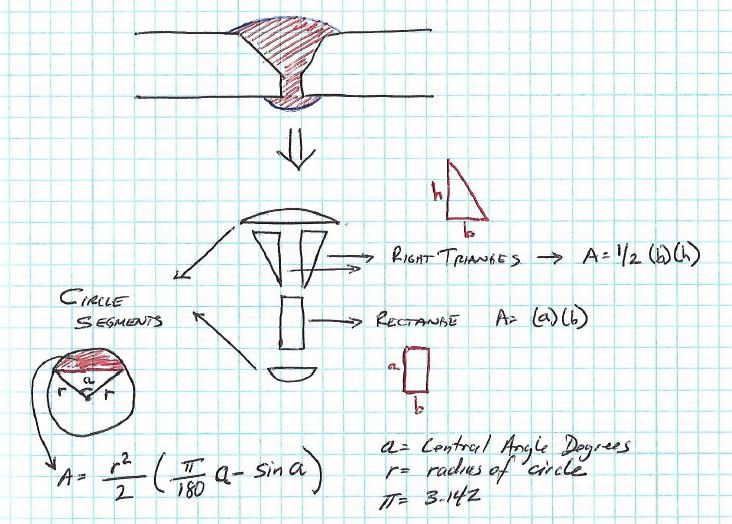

3 Divide this answer by 1000000000 to give weld volume in cubic metres. 2 05 05 A HEIGHT B BASE Volume of Weld 5B x A x 12 Weight of Steel 283 lb per cu. Per metre so in this example the volume is 507 cu.

June 25 2020 Author. Contributes to strength. Soman 2019 Effect of weld metal ferrite content on mechanical properties and stress corrosion cracking resistance in 22 Cr 5 Ni duplex stainless steel Welding in the World volume 63 pages 7938052019.

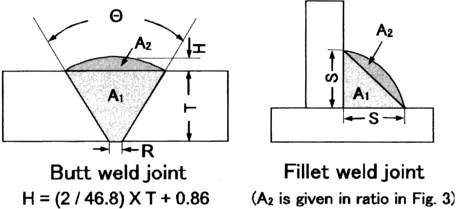

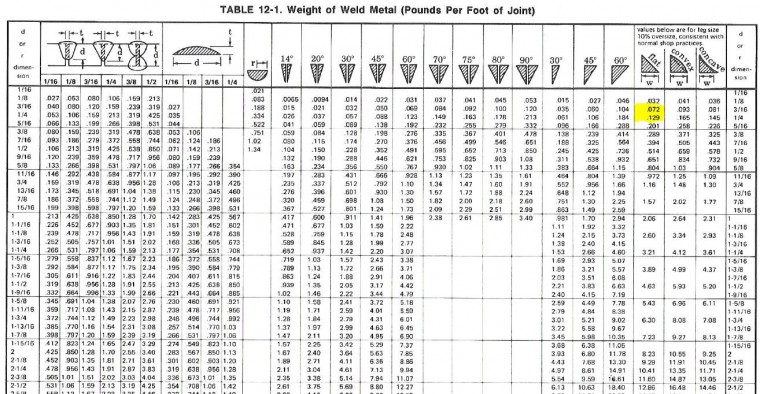

As a joint development between the voestalpine Steel Division and voestalpine Böhler Welding the app is currently. Table 12-1 in the Procedure Handbook of Arc Welding helps determine weld metal needs based on joint geometry. This video explain how to Calculating piping weld metal volume and weight-V butt weld jointsuse this method to calculate weight of electrodes and filler wire requirements in your piping systems.

How to calculate weld metal volume filler metal requirement. Welding Design Joint Design. 1 Calculate the weld area cross section of the weld including root and cap reinforcement in square millimetres.

Since we are welding carbon steel we use its density to calculate pounds of weld metal. This channel explain about piping isometricndtweldingcuttingpipe fit uppipe fit-upfabricationerectionelbow cuttingelbow center. We have to weld a total of 765 inches per part taken from the example on our previous post.

You should be able to do the rest. Weight of Weld 05 x 05 x 05 x 12 x283 424 lb. Any given welder will generate an equivalent of excess material for either weld type.

Conventionally the volume is often expressed in cubic centimetres cucm. Calculate volume of the weld joint using the pipe circumference. T Thickness or Fillet Size mm d.

1 Calculate the weld area cross section of the weld including root and cap reinforcement in square millimetres. Calculating Weight of Weld Metal Required so the total weld volume for each part is 00378 x 765 289 cubic inches. To determine the volume of metal you may need to purchase to complete a specific weld joint weld size and weld length using either Standard SAE or Metric units you select the weld joint and enter the needed dimensions of the weld size you will deposit.

Required By ASME QW 4036. Weld material volume refers to the volume of material enclosed within the triangular cross-sectional area identified in Fig 1 thus. After we find of work volume fillet weld volume than we can determine the amount of Welding Lenght Fillet Weld with below formula.

Determine of Welding Length m Formula. 2 Multiply weld area by pipe circumference weld length to give a weld. Formula of Welding Lenght Type Fillet Weld.

Weld Consumable Calculator Butt and Fillet Welds Process 99 Submerged Arc Welding 92 MIG GMAW short Arc 95 MIG GMAW spray arc 98 MIG GMAW pulsed arc 82 Flux Cored FCAW E70T-4 85 Flux Cored FCAW E71T-1 88 Flux Cored FCAWE70T-5 92 Flux Cored FCAW E70C-6M 80 Hard Facing Gas Covered 56 Stick MMAW GPs 59 Stick MMAW Low Hydrogen 60 Stick MMAW. 2 Multiply weld area by pipe circumference weld length to give a weld volume in cubic millimetres. Click to see full answer.

Fillet Weld Volume x Lenght of Welding 1000. 45 welds x 3in each 135 inches 1125 feet - 0072 lbft this yields 081 lbs per assembly 17 welds x 45in each 765 inches 6375 feet - 0129 lbft this yields 082 lbs per assembly. An additional 50 of excess material for one of hisher fillet welds is also likely to generate 50 excess in a butt weld.

Click to access case-study-smaw-weld-metal-cal-for-dss-weldpdf. Or S² x 1212 2178 x Lenght of Welding 1000. CALCULATING THE WEIGHT PER FOOT OF A FILLET WELD In the fillet weld shown below the area of the cross-section the triangle is equal to one half the base times the height the volume of the weld is equal to the area times the length and the.

Thickness of weld length. S Thikness or Fillet Size mm Fillet Weld Volume mm. The Welding Calculator App.

05t² 48 t 102418. Kotecki Sanjay N. The volume can then be calculated by multiplying the length of the weld by the area - ensuring that this length is also given in centimetres.

The Welding Calculator App supports the planning and optimization of welding tasks such as the calculation of cooling time preheating temperature or the calculation of the required filler metal quantities. So our totals are.

Calculating Weld Metal Requirements By Hand Welding Answers

How To Calculate Volume Of Trapezoidal Footing Engineering Notes Volume Construction Estimating Software

How To Calculate Weight Of Mild Steel Bar Civil Engineering Civil Engineering Software Engineering

Calculation Of Quantity Of Cement Sand And Brick In Wall Brick Calculator Cement Brick

Pin By Andi Rian On Kutipan Tank Calculator Volume

How To Calculate Quantity Of Steel In Truss Gusset Plates Steel Trusses Structural Engineering Design

Calculating Weld Metal Requirements By Hand Welding Answers Weld Simple Math High School Math

How To Work Out The Volume Of A Hollow Concrete Column Concrete Column Concrete Column Design Engineering Notes

Calculating Weight Of Weld Metal Required Welding Answers

0 comments:

Post a Comment