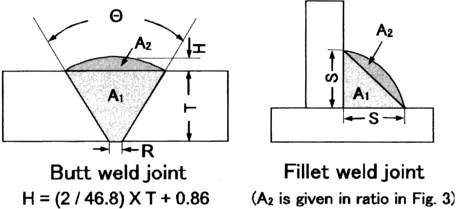

Area of Section A 1 weld metal mm2 Fig. For electric equipment the Welding-cost estimate should be calculated by multiplying Voltage by Amperage and dividing by 1000 and by the electric efficiency of the equipment times the price per kWhr kilo Watt hour time the operating factor actual arc-on time per hour.

Kawat Las Atau Elektroda Jenis Spesifikasi Ukuran Tebal Contoh Meja Las Proyek Pengelasan Pengelasan

So our totals are.

How to estimate welding rod. This paper presents a cost estimation model of weld assemblages. We have data from welder about Area Long Thichness as bellow. The study is about a proposition of an original definition of welding and preparing features attributed to each assemblages.

Determine the arc and its length burning area. As a worked example if the weld is in a plate 25cm thickness 03cm root gap 65 included angle b 3250. Let estimate the cost of the welding.

2 Multiply weld area by pipe circumference weld length to give a weld volume in cubic millimetres. The dimension c is given by tan b x t-r. 3 Divide this answer by 1000000000 to give weld volume in cubic metres.

A process to determine the total costs of welding will be outlined below. In this case for example the widh of las is 8 mm then we can compute. Consumption of welding consumables kg A 1.

1 Calculate the weld area cross section of the weld including root and cap reinforcement in square millimetres. It is based on knowledge modelling at the level of process and product perception. Thus the weld metal weight therefore theoretical weight xQ factor.

Create and compare full costing reports to make sure you get the best value for money for your job while making sure you meet your project timescales in the most cost-effective manner possible. An estimator himself must choos e the v alues and define the man hours taking into account all the elements that might hav e any influence on them. ø Sch-10 Sch-20 Sch-30 STD Sch-40 Sch-60 XS Sch-80 Sch-120 Sch-160 XXS.

We Offer Specialized Welding Solutions in ER2594 ER2209 2205 DSS 2507 Duplex SDSS. Stocks in huge qty. Using an arbitrary 50 labor and overhead rate and the market list price for a wide range of welding consumables an estimation of the cost for one pound of deposited weld metal is listed in Table 1.

Area of Section A 2 reinforcement mm2 Fig. Ad We Stock Duplex Super Duplex Electrodes. Table 12-1 in the Procedure Handbook of Arc Welding helps determine weld metal needs based on joint geometry.

Now we know that the actual weight used is much more than the theoretical weight since there are butt losseselectrode coating has to be accounted for and there is convexity at the top and root of joint. Ok lets us started to expalin how to calculating welding rodwire requirement from the simple welding. 45 welds x 3in each 135 inches 1125 feet - 0072 lbft this yields 081 lbs per assembly 17 welds x 45in each 765 inches 6375 feet - 0129 lbft this yields 082 lbs per assembly.

50 horizontal welding 50 overhead 2. 3 Divide this answer by 1000000000 to give weld volume in cubic metres. Ad We Stock Duplex Super Duplex Electrodes.

1 Calculating Filler Metal Consumption The number of pounds of welding electrodes or welding wire necessary to complete a given weld joint may be calculated by the formula. Tan 325 0637 and with a cap height of 02cm we have- c tan325 x 25 0637 x 25 159cm w 2 0637x25 03 3485cm so the area of the cap 3485x022 0348 sq. Welding Estimator is a quick and easy-to-use weld welding procedure and welding project cost estimation tool which allows you to find the most cost-effective process for your weld.

The total area of the two red regions is therefore given by the formula 2t-rtan b x t-r2 or t-rtan b x t-r. Stocks in huge qty. Five different operating factors were used the lowest being 20 percent and the highest 60 percent where operating factor is defined as the percentage of a welders time that he is actually welding.

How do I calculate how much welding rod I need. With this deposition the rate of the process. 2 Multiply weld area by pipe circumference weld length to give a weld volume in cubic millimetres.

40ft straight welding intervals welding 40ft of pipe cut in half on to a plate for a total length of 120ft welding on both sides of the resulting 12 sections or c would be a total of 240ft. First step we must find the volume of welding ussualy we used triangular pyramid to simplify the calculation. A sa ying S witch on your b rain bef ore switching on the compu ter should be f ollowed.

C A1 A2 x L x GE x 110. P Pounds of electrode or wire required W Weight per foot of weld metal L Length of weld feet E Deposition efficiency Weight Per Foot of Weld Metal Calculating the weight of weld metal requires that. 2 Multiply weld area by pipe circumference weld length to.

1 Calculate the weld area cross section of the weld including root and cap reinforcement in square millimetres. Only when the relev ant man hours are estimated and selected a computer can be used. It is based on the product decomposition into parts and then into assemblages.

1 Calculate the weld area cross section of the weld including root and cap reinforcement in square millimetres. These diagrams were developed using the calculations obtained by the following equation for both groove and fillet welding joints under the prerequisites given below. Welding Machine Portable 123 kVA 20-300A 1.

Multiply this volume with density to get theoreticall weight of weld metal. We Offer Specialized Welding Solutions in ER2594 ER2209 2205 DSS 2507 Duplex SDSS. P WL E Where.

Stick Electrode Filler Rod Guide Welding Consumables Welding Rods Types Of Welding Welding

Understanding Arc Welding Rods Classification And Which Ones To Get Welding Rods Welding Rod Chart Arc Welding

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

The Ultimate Guide To Welding Rod Sizes And Classifications Including The 7018 6013 6011 And 6010 Welding Welding Table Welding Projects Welding Electrodes

A Guide To Welding Electrodes On Ships Part 1

Welding Electrode Numbers Mean Google Search Smaw Welding Welding Welding Electrodes

Weldcote Nickel 55 Cast Iron Welding Electrode Repair 3 32 1 Lb Walmart Com In 2021 Welding Electrodes Welding Cast Iron Welding Rods

Discovering The 7018 6013 6011 And 6010 Welding Rod Sizes Welding Rods Welding Table Welding Projects

0 comments:

Post a Comment