The more massive the object the longer it will stay hot. O The last line of defense against jobsite fires is fire watch.

Welding And Cutting Safety Procedure Media K3 Indonesia

Defines the required controls to eliminate or prevent hazards related to hot work.

Welding cutting and hot work toolbox talk. It can also be displayed in the workplace to remind workers of safety precautions when performing welding grinding cutting soldering etc. Gas testing should be done around 15 meter radius of hot work. Operations that create a spark or flame such as welding and soldering are referred to as hot work.

With our tool box talks kit click here. Whenever possible move objects to a safe place before heating cutting or welding. Do not cut or weld any steel drum or other vessel that might have contained flammables until it has been steam purged and tested.

Dont cut or weld in the presence of flammable liquids or vapors in the presence of lint or dust or on. Monitors the Hot Work area for changing conditions detects fires and extinguishes them if possible. It is likely to be hot enough to cause a severe burn.

Welding is a multi-risk operation to both operatives and others in the vicinity that must be strictly controlled. Keep fire extinguishers handy and be fully knowledgeable in its use. Here are the Hot Work Safety Dos and Donts that can be shared or communicated to workers during the Toolbox Talk Meeting.

The hot work permit is really nothing more than a formal checklist to ensure that potential safety issues are addressed in the area you will be doing the work and that someone else agrees it is safe to do the work. This is the second of two toolbox talks on health and safety for welding. Never touch something that has just been welded on.

Welding work keeping safe. O Be sure to stop all hot work at least 30 minutes before leaving the jobsite. It covers local exhaust ventilation and respiratory protective equipment which are controls that can be used to protect workers health.

Welding and Cutting Safety Toolbox Talk Summer 2009 The SHE Committee prepares bi-monthly safety training programs for precasters to use for conducting safety programs at their plant. This is true for direct exposure to UV radiation as well as radiation that is reflected from metal surfaces walls and ceilings. Hot work procedures must be understood by operators and building managers and all occupants should be familiar with basic safe work practices.

Welding Operations Toolbox Talk. Safety Toolbox Talk Webmaster. Fires are often the result of the quick five minute job in areas not intended for welding or cutting.

Special precautions are necessary to perform hot work safely. Outline the hazards related to hot work. Where hot works are carried out at elevated work areas where fire spatter may fall to the ground below the area directly below shall be covered by fire blanket and access below shall be barricaded.

Tool Box Talk - Welding Cutting and grinding. Remove or effectively screen all fire hazards where the welding job is to take place. This includes but is not limited to welding burning cutting brazing grinding and soldering.

This includes but is not limited to welding burning cutting brazing grinding and soldering. Symptoms of Welders Flash Include. Harvard EHSEM has developed a Hot Work Standard.

Welding soldering and cutting are examples of hot work. To learn more about TBTs and view and download 60 covering everything. This type of extraction can work well for small welding jobs but for long sections of weld other means of control are.

Below you find a complete free tool box talk on Welding Operations. Move work to a safe place. Provide and introduction what hot work is and why it is important to manage.

Flushing with water is not sufficient. Getting a hot work permit before performing hot work is just one of steps involved in a hot work management program that helps to reduce the risk of starting a fire by hot work in. Work at all time.

Do not assume danger has passed just because the person welding put down the welding or cutting torch. Cutting torch or plasma cutter or any bright source of light that has an ultraviolet component can cause welding flash. Welding grinding requirements.

Our hot works toolbox talk is split up in following sections. Hot Work Permit If welding cutting or brazing operations cannot be conducted in an areashop designed to facilitate safe Hot Work operations then these activities require a Hot Work permit as defined by your. To Prevent Cutting or Welding Fires.

35909090909091 1 1 1 1 1 1 1 1 1 1 Rating 359 22 Votes A Hot Work Permit is required for any temporary operation involving open flames or producing heat andor sparks. Of fume breathed in for example standing over the weld will cause the hot fumes to envelop your visor and. Never try to get the attention of the person doing the welding unless there is an emergency.

Welding location shall be fully covered with fire blanket. O Maintaining good housekeeping practices in your work areas and take steps to contain your welding sparks and other ignition sources such as sparks generated from grinding and pipe cutting. Pain ranging from a mild feeling of eye pressure to.

Welding booth shall be made at Welding location. A hot work permit is required for any temporary operation outside a designated welding or hot work bay involving open flames or producing heat andor sparks. This months featured safety program is on welding and cutting safety.

If work cant be moved remove combustibles from area.

Hot Work Safety Dos And Don Ts Welding And Cutting Safety Precautions Hse And Fire Protection Safety Ohsa Health Environment Process Safety Occupational Diseases

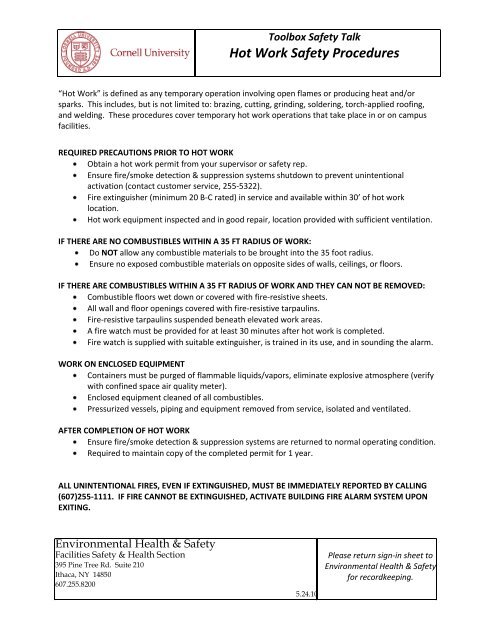

Hot Work Toolbox Talk Environmental Health Safety

Hot Work Safety Training Welding Cutting Brazing Ppt Video Online Download

Hot Work Hazards September 2017 Safety Health Magazine

Toolbox Talk Welding Important Note To Managers The

Https Www Jjwhiteinc Com Wp Content Uploads 2019 02 Toolbox Training 2 11 2019 Pdf

Workplace Safety Poster Highlighting The Danger And Precautions For Power Tools A3 Size Safety Safety Posters Occupational Health And Safety Power Tool Safety

Hot Work Toolbox Talk Environment Health And Safety

Toolbox Talk 2 Welding Work Keeping Safe Worksafe

0 comments:

Post a Comment