CCCV welders operate similarily to CC MIG welders except that they possess multi-process capabilities meaning that they are capable of performing flux-cored stick and even TIG processes as well as MIG. Furthermore if the welding.

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

When welding surges in the arc voltage and welding current can cause an increased level of solidity and lower yield durability.

Welding yield meaning. DC AC 45 Ferrocraft 22 ocv Typical All Weld Metal Mechanical Properties. So when you weld a wide flange given the parameters above you are overmatching 70 ksi weld vs. Lloyds Register of Shipping Grade 2Y American Bureau of Shipping Grade 2.

We typically use E70 electrodes which have a yield strength of 70 ksi. But one of the most popular electrodes for beginners is the E6013. In addition the procedure does enable an actual residual stress distribution to be incorporated if this has been measured.

50 Yield Tensile Yield Tensile E70 Fy 58 ksi 400 MPa Fu 70 ksi 480 MPa Matching tensile strengths often do not result in matching yield strengths. Tensile Strength measure of the maximum stress that a metal can support before fracture begins. As you can see electrodes are defined and characterized by four numbers.

Length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length. A weld made to hold the parts of a weld in proper alignment before the final welds are made. Fracture Toughness the ability of a metal to absorb energy in the presence of a sharp notch often when subjected to an impact load.

Yield Stress 440 MPa Tensile Strength 512 MPa Elongation 25 CVN Impact Values 60J av 0C. Weld is 5 ksi 30 MPa greater Weld is between 2 ksi 15 MPa greater to 20 ksi 135 MPa less Weld is 22 ksi 150 MPa greater Weld is between 12 ksi 80 MPa greater to 10 ksi 70 MPa less A572 Gr. In your case significant yielding means strain and extension without much added load whereas in the normal structural situationsdetails you can tolerate some yielding start of hinge formation etc because some distribution and added load capy.

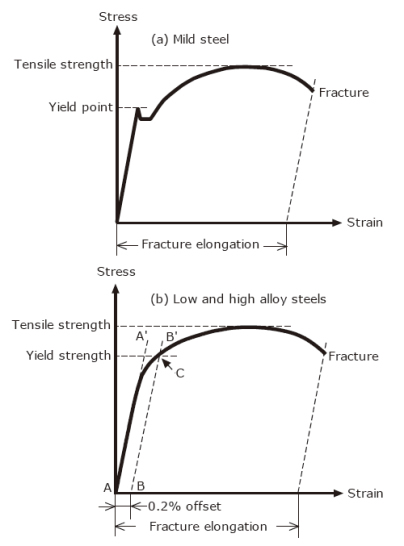

In other words the yield point is the stress at which a marked increase in strain occurs with little or no increase in stress. A metals ability. Yield Strength measure of the stress a metal can support before deforming.

The assumption of yield residual stress has been criticised as conservative which it is and intended to be. By raising the welding velocity you may see an increase in the hardness of welds. The very first two numbers 60 stand for its tensile strength which means the E6013s tensile strength is up to 59700 pounds per inch or almost 60000 pounds per inch and its yield strength is 67700 psi.

North Americas Largest Fleet of Welding and Positioning Equipment WELDING ELECTRODE CLASSIFICATIONS MILD STEEL COATED ELECTRODES E7018-X E Indicates that this is an electrode 70 Indicates how strong this electrode is when welded. Depending on the electrode you can undermatch overmatch or match the weld strength to the base material. Exists before a failure mechanism forms.

As Welded Pertaining to the condition of weld metal welded joints and weldments after welding but prior to any subsequent thermal mechanical or chemical treatments. The yield point is the load per unit area value at which a marked increase in deformation of the specimen occurs with little or no increase of load. For wide flanges we typically use 50 ksi steel.

Measured in thousands of. ASME American Society of Mechanical Engineers. E6010 6200070000 5200058000 22 to 28 35 e6011 6200073000 5200061000 e6012 6800078000 5500065000 17 to 22 25.

However it is often forgotten that the procedure allows this stress to be relaxed to a lower value depending on the applied stress and flaw size. 171 physical properties of e60 e70 series electrodes typical values aws astm tensile yield redin area electrode strength strength elongation min. Yield strength is the maximum stress that can be applied before it begins to change shape permanently.

Stress in a fillet weld. Typical All Weld Metal Analysis. This is an approximation of the elastic limit of the steel.

The effective area shall be the ef-fective weld length multiplied by the effective throat. The preferred polarity for DC fillet welding is DC. It can also impact ductile durability and impact toughness.

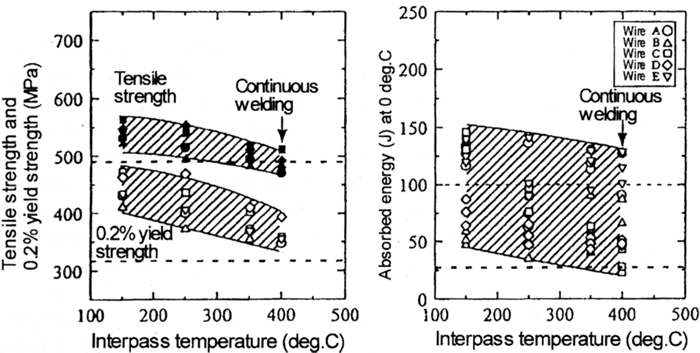

The weld metal should achieve 70ksi tensile strength 27J at -40C 58 to 80ksi yield strength at high heat input a maximum 90ksi at low heat input and a diffusible hydrogen content of less than 5ml of H2100g of deposited weld metal. How to use wield in a sentence. Wield definition is - to deal successfully with.

If stress is added to the metal but does not reach the yield point it will return to its original shape after the stress is removed.

Effect Of Welding Parameters On The Yield Strength Of The Welded Joint Download Scientific Diagram

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

Tensile Strength Of Steel Vs Yield Strength Of Steel Clifton Steel

What Dose It Mean Yield Strength Of Re Bar Quora

Effect Of Welding Parameters On The Yield Strength Of The Welded Joint Download Scientific Diagram

Https Www Structuralintegrity Eu Pdf Esis Tc 1 Esis Tc1 Freiburg Zerbst Pdf

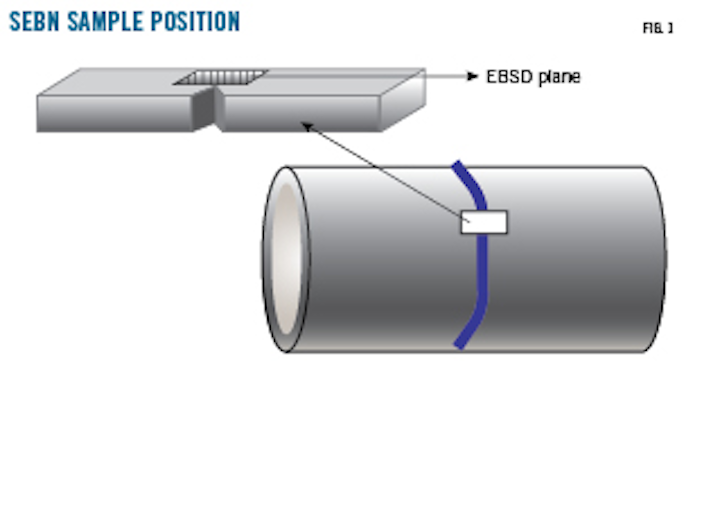

X80 Pipe Welding Technique Yields Reliability Cost Advantages Oil Gas Journal

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

What Is The Tensile Strength Of Mig Welding Quora

0 comments:

Post a Comment