Most of the time ARGON and HELIUM gases use for TIG welding. Trusted China Suppliers Verified by SGS.

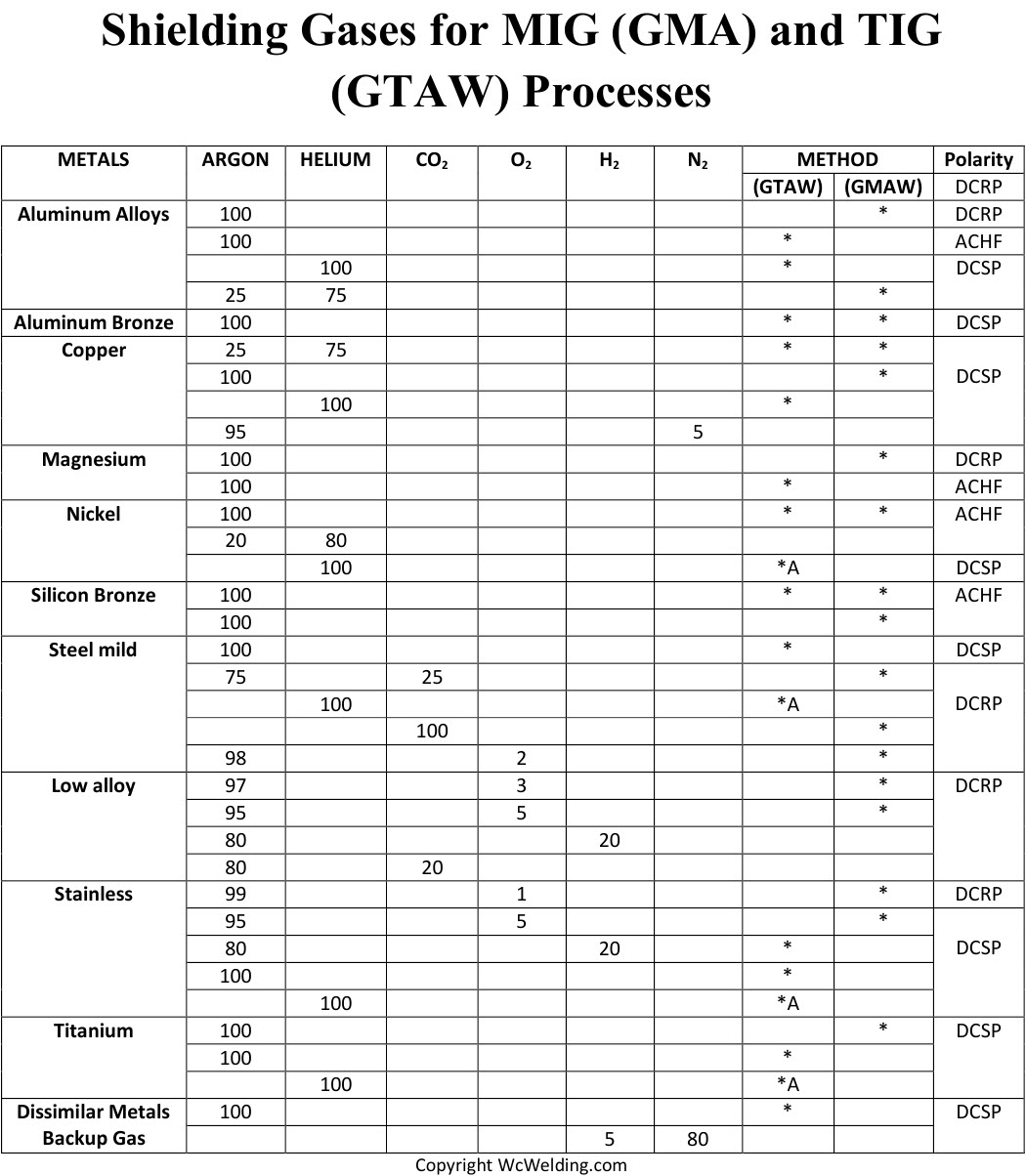

Recommendations for shielding gases used in TIG welding of different stainless steels are given in the table.

Best shielding gas for tig welding stainless steel. For instance the addition of hydrogen gives a similar but much stronger. It produces a stable welding arc and is suitable for all grades of stainless steel. Typically pure argon provides the best results when welding thinner austenitic stainless steel but the addition of small percentages of helium is not uncommon when better penetration and faster travel speeds are desired especially on thicker pieces.

I only know from past experience that an ArgonHydrogen mixture for welding stainless does affect the GTAW or TIG process in a positive way. Shielding gases for TIGGTAW welding. As a general rule argon is the first choice for welding this material especially thinner gauge.

Trusted China Suppliers Verified by SGS. In most cases the gas used will be C2 or 2 Carbon Dioxide and 98 Argon. Argon is the simplest gas for TIG welding stainless steels and nickel alloys.

I work for a contractor who specializes in automatic tube welding or Orbital welding where we use the GTAW fusion process to join thin wall stainless steel tubing usually 316L. For thicker gauges adding small percentages of hydrogen allow increased travel speeds. It produces a stable welding arc and is suitable for all grades of stainless steel.

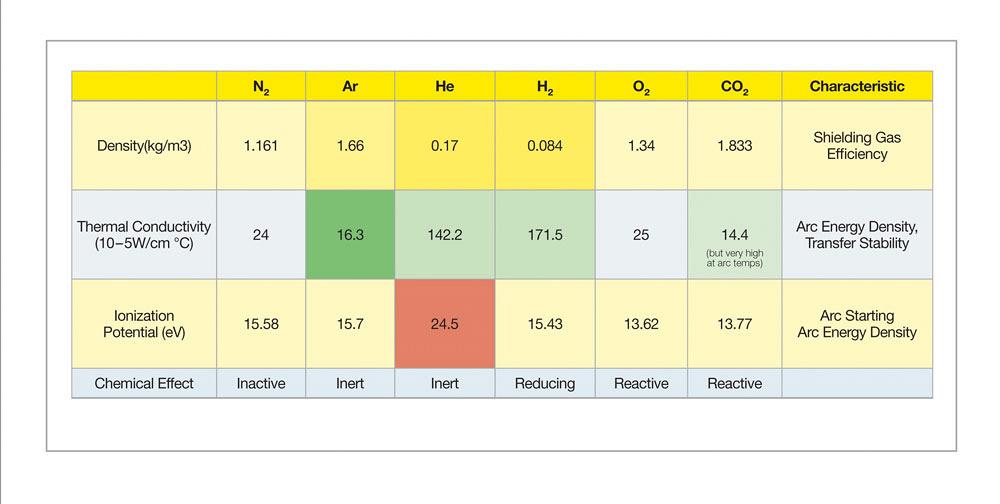

Welding stainless steel requires selecting shielding gases that preserve its metallurgical composition and associated physical and mechanical properties. Common shielding gas elements for stainless steel include argon helium oxygen carbon dioxide nitrogen and hydrogen. Argon provides a good combination of features that produce clean high-quality TIG welds in carbon steel.

TIG welding shielding gases are going to be argon or helium or a mixture of the two. For TIG and plasma welding. Please register or sign in to view prices and order.

Ad China Tig Welding Machines. However as the thickness of the material increases. The next best thing to shielding the back side of a weld with argon is to use a piece of copper for backing.

The benefits of argon as a shielding gas include. Copper removes heat and traps a small amount of shielding gas and makes the. Welding of stainless steel is typically done with mixture of Argon and Carbon Dioxide gasses that can be as low as 2 carbon Dioxide to as high as 25 carbon Dioxide.

If not properly shielded with argon your metal piece will sugar another word for oxidation or granulation. Several gases utilize for different welding processes but in TIG welding not every gas is consumed. Sugared welds cannot be used as they contain deep pits and holes that can easily transform into cracks.

Argon is the best choice for shielding gas used in TIG welding stainless steel. Ad China Tig Welding Machines. The best gas for TIG welding carbon steel is argon.

Other gasses will work to TIG weld carbon steel but argon is the best combination of price and. But argon is the most commonly used shielding gas for TIG welding. Using the correct type and amount of shielding gas is key when welding austenitic stainless steel and it is also another way to prevent carbide precipitation.

All-purpose shielding gas for general fabrication of carbon steel typically in the 4-12mm range. For plasma-arc welding the gas types with hydrogen additions in the table are mostly used as plasma gas and pure argon as shielding gas. The reason behind this is that the inert gas usage for the TIG welding process protects the actual welding portion.

The normal gas for TIG welding is argon Ar. In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide. Argon or argonhelium mixtures can be used for welding all grades.

If you want a more stable arc and good cleaning action then argon is the gas you want for TIG welding. Copper has an almost mystical property to it when you back up a weld. 08 The right gas mixtures for TIG and plasma welding Argon 46 Argon is the simplest gas for TIG welding stainless steels and nickel alloys.

Helium He can be added to increase penetration and fluidity of the weld pool. In some cases nitrogen N 2 andor hydrogen H 2 can be added to achieve special properties.

Shielding Stainless Steel Correctly For Welding

Awesome Tig Welding Welding Metal Welding

Pin By Ixl Idol On Woodwork Shop In 2021 Gas Saver Welding And Fabrication Welding Projects

Tig Welding Stainless Steel Gas Coverage Maine Welding Company

What Is Gtaw In Welding Gtaw Welding Gas Tungsten Arc Welding

How To Really Sharpen Tungsten For Precision Stainless Tig Welding No T Tig Welding Types Of Welding Welding And Fabrication

The Best Tig Welding Nozzle For Downpipe Stainless Welding Tig Welding Metal Working

Tig Welding Stainless Steel The Effects Of Gas Flow And Gas Lenses Youtube

0 comments:

Post a Comment