Laser welding is typically a faster welding process compared to other welding processes due to its high power density at the materials surface. Gas metal arc welding GMAW commonly referred to as metal inert gas MIG welding is another common method used for aluminum welding.

Like other fusion based processes including arc welding laser beams can be used to weld many series of aluminium alloys.

Gas welding thin aluminum. Weld and Cut in one kit with this torch from Eastwood thats Made In The. For welding thin aluminum the shielding gas of choice is argon. Aluminum from 132 to 1 in.

Generally you will be using a pure argon shielding gas when you are MIG welding aluminum. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. This type of welding typically has faster travel speeds and higher deposition rates than TIG welding affecting the weld quality.

Thicker sections of aluminum pieces may need some mixture of argon and helium for thicker sections where high heat input welds are being deposited. Learn the tricks to Gas Welding aluminum sheet metal with Mike from Cobra Torches. On thin gauge aluminum like this you will only need to pass the flame over the weld seam for a short time before beginning to weld.

Getting the tubing hot enough may take 4 to 5 minutes. Heat Up Aluminum Clamp up the tubing and start heating the aluminum with a propane torch. 08 to 254 mm thick may be gas welded.

Oxyhydrogen welding permits a wider range of gas pressures than acetylene without losing the desired slightly reducing flame. OK maybe not as old as that but it was an early process that is still a very effective form of welding particularly thin material or aluminum. Setting Up The Shielding Gas.

On the other hand conventional aluminum TIG welds are susceptible to porosity if not done correctly. Heavier material is seldom gas welded as heat dissipation is so rapid that it is difficult to apply sufficient heat with a torch. Welding aluminum with gas and hydrogen is a process that can easily be learned even by a beginner welder.

Ad Find China Manufacturers Of Aluminum Welding. It is an accident waiting to happen if the weld gets contaminated. Ad Find China Manufacturers Of Aluminum Welding.

Gas welding aluminum increased weld density. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. Gas welding is a form of welding that is old as the hills.

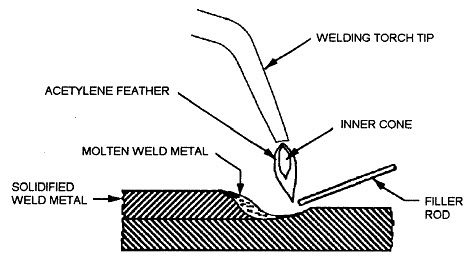

Start by aiming your flame at the center of the seam and as soon as you begin to see the metal get shiny at the very center of the seam you will want to begin dipping your filler rod. While the use of a higher-cost helium blend is beneficial in getting more heat into thick sections welders will find no benefit in using it on thin sections. Aluminum will start to melt at 1200deg Fahrenheit but the brazing rod will melt at around 700deg so we want to get the aluminum hot enough to melt the rod without melting the tubing.

Pure argon is the preferred shielding gas for welding thin sections of aluminum.

Aluminum Welding Guide Tips Techniques Weld Guru

Aluminum Gas Welding The Basics Weld Guru

How To Gas Weld Aluminum Sheet Metal Eastwood Blog

How To Gas Weld Aluminum Sheet Metal With A Cobra Torch From Eastwood Youtube

Aluminum Gas Welding The Basics Weld Guru

How To Weld Aluminum Australian General Engineering Vietnam Metal Fabrication Vietnam

How To Gas Weld Aluminum Sheet Metal Eastwood Blog

Aluminum Gas Welding The Basics Weld Guru

0 comments:

Post a Comment