Move across the middle of the joint slowly enough so that the weld puddle can catch up and pause slightly at the sides to ensure solid tie-in to the sidewall. Click to read more about these methods.

How To 3 Of Box Bar Joint Together Without Welding Youtube

This allows for sufficient penetration of the weld arc to melt both sides to a molten state so the filler metal bonds through the sectional thickness of the metal.

How to remove welding joints at home. Again ensure that the wire type and diameters and the gas and the gas mixture are compatible. To test the joint pick up the lead and try to pull it apart. Chip off the slag with a welding hammer and then use a 36-grit grinding wheel to knock the beads down to the surrounding metal.

Smooth out the rough ridges on the weld to make it look consistent with the rest of the plastic. However the choice of method depends largely on the scope of the problem. Hand screws are easy to source and simple to use.

However tacking ensures the lead cant pull apart as you work. For thinner welds a straight line bead may be sufficient. Brazing aluminum with a propane torch and brazing rodsWatch the full build of the lift top coffee table.

If the metal consists of two pieces that are to be joined in the welding process you may need to prep or weld prep them by grinding a beveled edge on the sides that are to be joined. If you cant pull it apart then you secured it successfully. 242 Length 2421 Effective Length Straight.

Line the cutting wheel up with the mark on the metal and start the saw or grinder with its trigger. The joint should be prepared in such a way to allow the welder to maintain the proper wire extension and still access the bottom of the weld joint. Many of these tools are economical enough to be purchased by the home hobby welder for use in their shops.

Keep the wheel perpendicular to the surface of the metal. Many smaller hand-operated hydraulic press tools are available in and around small shops. When welding vertical up if you focus on welding the sides of the joint the middle will take care of itself.

Step 4 Allow the wheel to cut down through the metal then push the saw or grinder away from your body. Sand the welded joint down with 120-grit sandpaper. Apply light pressure to the weld rubbing the sandpaper back and forth across it.

Several methods are commonly used to remove discoloration on stainless steel after welding electrochemical cleaning chemical pickling and mechanical grinding brushing are just few of them. Hydraulic presses make the process even easier. You dont always need to tack weld.

If youre sure you can get a clean weld without pinning the metal together then skip to the regular weld. Prepare the metal to be welded. 3 mm for any groove detail requiring such deduction see Figure 33 and Annex I.

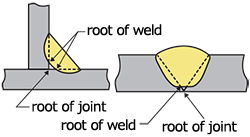

Throat of a combination partial joint penetration groove weld and a fillet weld shall be the shortest distance from the joint root to the weld face of the diagrammatic weld minus 18 in.

Different Types Of Welding Defects Types Of Welding What Is Welding Welding

Steel Metal Flat Sheet Plate Polisher Welded Joints Grinder Flat Sheets Weld Sheet

Welding Joints And Symbols Welding Projects Welding Training Welding And Fabrication

Tanker Vessel Circular Welding Seam Grinder Grinding Machine Vessel Circular

Your Guide To Reading Symbols In Welding Best Auto Darkening Welding Helmets Guide 2015 Soldadura Soldadura Tig

6 Basic Weld Joints Joint Basic Welding

Welding References Education Center Kobelco Kobe Steel Ltd

Welded Joints Types Weldability And Testing Of Weldments

0 comments:

Post a Comment