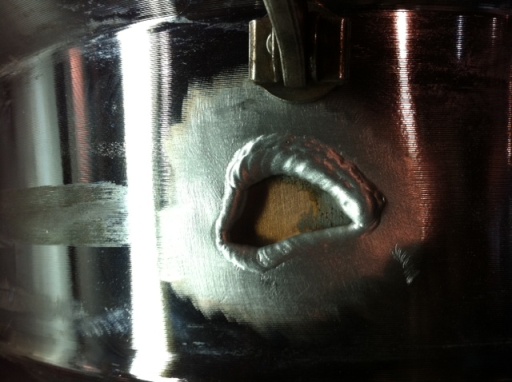

Level the welds out. Aluminium alloy must be welded with a process called TIG Tungsten Inert Gas welding.

How To Weld Aluminum Car Wheel Car Best Wheels

Make sure you have taken all the safety measurements possible including glasses boots and gloves.

How to tig weld aluminum rim. The skill of the welder. With a little practice and some basic best practices to help beginning welders you can produce the results you want. In one hand a TIG welder holds a TIG torch that is aimed at the area where one needs to start welding.

The trick to not blowing a hole in the can is to begin the arc on the filler wire. The bead is much thinner and weaker and the process burns the heck out the surrounding alloy weakening the entyre area around the weld. The skill of the welder.

TIG welding cast aluminum should always be done with pure argon gas not an argonCO2 mix as is common with MIG welding. Start Welding the backside of the aluminum wheel first as it wont be seen from outside. Stick Welding Aluminum and a little known trick for Tig welding.

Ive seen many aluminium wheels that were MIG Metal Inert Gas welded and its a disaster. If possible preheat the aluminum up to 300 degrees Fahrenheit that will help you easily weld this tricky metal. It does not have to be a big thick piece of copper either.

For welds needing deeper. Aluminum alloy must be welded with a process called TIG tungsten inert gas welding. A clean ss wire brush a piece of copper for backing tig gloves a tig finger and a clamp to hold the copper backing in place.

Watch hand and torch placement. Not my favorite thing but Im going to try a little quarter inch lap joint and well do a cut and etch test on it compare results from stick welding cold with no pre-heat to weld it while its hot from. The other hand is reserved for the metal filler rod.

We cover basics for beginners who want to TIG wel. Use an AC polarity Aluminum easily forms an oxide layer that is not easily visible to the naked eye. You can use MIG wire as a filler and then start at 20 amps.

The oxide layer can be cleaned using a carbide cutter but there are high chances that it will develop back once welding begins. The copper backing is key. When you get a puddle formed bump your amps to 25 and begin running beads around switching the can between welds.

Since youre going to weld aluminum using TIG welding youll need to choose either the DC positive or DC negative power. After that start to weld the front side while some heat is still available on the wheel. TIG welders should be aware of this factor when welding aluminum.

A TIG welder basically comes with both AC and DC power options. Aluminum oxide forms on the surface of all aluminum alloys. Hold the torch at 10-degree angle and the filler at 90-degree angle to work effectively with the aluminum.

The coating can prevent a TIG welder aluminum from seeing the weld puddle properly. Follow our four steps below to practice and advance your TIG welding skills with aluminum. The filler metal is a simple wire that the welder feeds and dips by hand which is then melted into the arc.

How to TIG Weld Aluminum With AC When your TIG machine has an ACDC switch AC is the way to go for welding aluminum. TIG welding also uses shielding gas for protecting the overall process from atmospheric contamination. Use a flap disc on the angle grinder.

It helps the puddle to flow evenly. Today were doing a little stick welding aluminum. Finally our foot hovers over a.

Even an 18 thick piece of copper sheet works and is able to be formed to the contour of the back side of the part you are welding. One of the things that makes welding aluminum different than welding steel is Aluminums oxide layer. The bead is much thinner and weaker and the process burns the heck out the surrounding alloy weakening the entire area around the weld.

Learn how to TIG Weld. Aluminum wheels that are MIG metal inert gas welded are a disaster. Learning to TIG aluminum.

TIG welding aluminum doesnt need to be intimidating. This includes argon and a slight composition of helium gas. Ensure there are no pores in the welding.

You can weld on Aluminum cans using a 116 tungsten electrode on your dynasty 200. This video is sponsored by LincolnElectric to demonstrate the TIG 200 Square Wave.

Aluminum Wheel Repair By Welding

How To Tig Weld Aluminum Youtube

The Black Art Of Tig Welding Aluminum Crash Course Edition Eastwood Blog

Tig Welding Aluminum Fabrication Process Is Amazing

Tig Welding Aluminum Rim Repair Youtube

Aluminum Wheel Repair By Welding

Aluminum Rim Welding Tips And Tricks On Wheel Repair Youtube

How To Tig Weld Aluminum In Depth Youtube

0 comments:

Post a Comment