This also serves to decrease the overhang of the roof sheeting where it extends beyond the purlin to the ridge. This does require a.

I am doing a lean to roof approx 126m length with approx 42m spans.

How to weld metal purlins. The purlins are all 6m long so I will need another 06m or so joined into two lengths. The steel panel can span quite a large distance the vertical walls typically will have something to screw into about every 4 feet. Purlins need to be placed on the nodes of the trusses rather than on the members themselves in order to avoid secondary bending.

Not everybody can weld. When channels are used the ridge purlin is placed as close to the peak of the truss as possible in order to shorten the connection to the purlin on the opposite side of the centerline see Figure 2. In short its strong and durable.

Purlins are non-pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern. Easier to handle The higher strength-to-lower weight ratio means purlins made from GALVASPAN steel are easier to transport and handle on site. 60106011 is a deep penetrating electrode which you definitely DO NOT WANT in this case.

Then weld with 18 7018. Do all roofing projects require purlins. Specification Maintaining the correct specification of purlins girts and bridging is very important.

C Purlin - Cee or C purlins are shaped like a squared-off letter C. Be a craftsman and grind the primer off weld with a 7018 and primer the weld zone. From what I have seen personally galvalume sheet can be welded but you have to crank up the welding machine to overcome the coatings resistance or else ground the machine to an area where the coating has been ground away.

We do recommend it however. The entire welding process should only last 3 to 6 seconds for most cases but welding times can vary depending on different equipment and techniques used. They are available in either bolt on or weld on versions and are pre drilled to suit standard purlin holes.

If its really bad paint keep a 532 6010 series for a burn through pass a quick way of getting rid of paint. Steel is made from hi-tensile steel which means it has a strength-to-weight ratio approximately 60 greater than hot rolled steel. Yes I know Z section purlins lock together but I do not have Z section purlins.

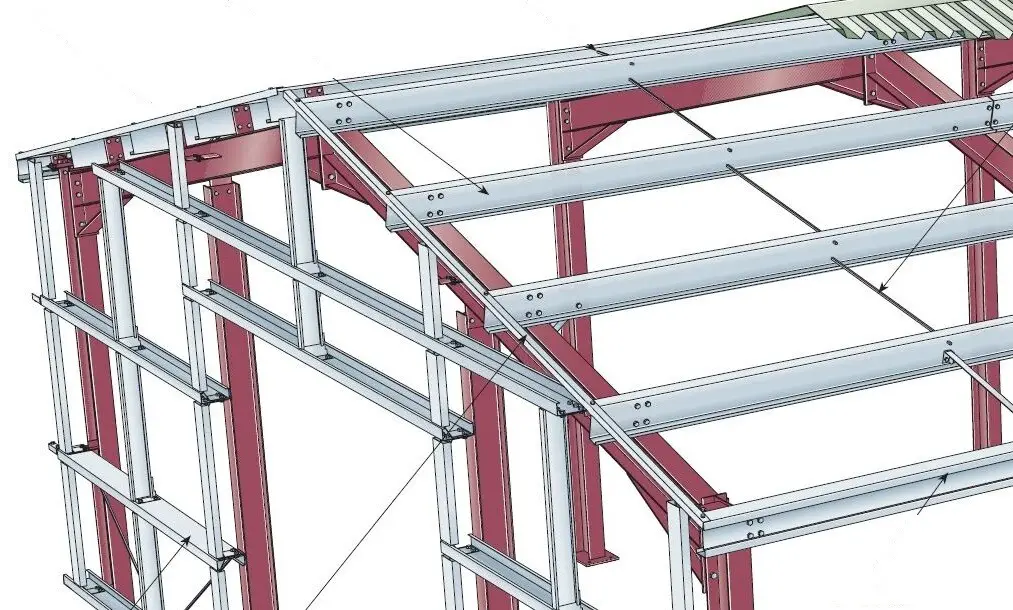

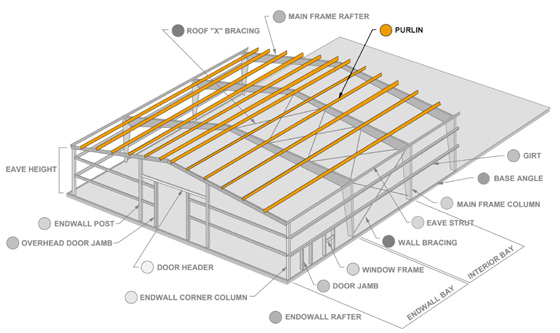

What are purlins. Welding purlin to thick metal Whichever you use concentrate the puddle on the heavier metal and using a weave wash the puddle onto the 14 ga back to the beam and weavewash again. Cold-formed C and Z Cee and Zed sections are recommended for purlins in metal buildings as they are light stiff and strong yet allow for easy transportation fabrication and installation.

You can bump that number up a little like if you wanted a 10 foot wall you could put the middle support at 5 foot and then screwed in top and bottom. Other coatings grades and materials may be available subject to inquiry. They are 18 inch taller than the cee or zee profile so the end of the profile will slip in perpendicular to the channel.

It is important that the finished weld penetrates both the deck and the supporting member. Burning through paint sucks and some paints it is toxic to breath. Cleats are used to secure purlins to the structure of your building.

Bridging and Purlin accessories are manufactured from steel with a minimum yield of 300 MPa and galvanised coating of Z275 or zinc aluminium alloy AZ150 coating. The heat produced in welding will affect the material properties of the high yield strength cold-formed steel used in purlins. I was thinking of welding them then fish plating them with some 25mm gal plate I have on hand.

It is intended for thin metal and is very operator-friendly. In many instances considerable stress concentrations are likely to arise even with good quality welding. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

6013 will give you very good results. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to. Measure the width and height of the roof and record the measurements.

Cladding fixes easier and faster. The welding or hot cutting of purlins girts or bridging is not recommended. Attached at floor 4 feet up 8 feet up etc.

6013 is the rod you should be burning. Receiving Channel is used to receive purlins or girts at the ends of the building structure. Lay the first purlin at the ridge of the roof down to the chalk line beginning at either corner.

The top and bottom of the profile are. They are often used for structural support in walls and as floor joists in addition to roofs. Step 2 Snap a chalk line horizontally across the roof two feet down from the top.

Design Of Roof Purlins Structville

Why You Should Use Metal Building Purlins For Your Roof

Purlins Cee And Zed Steel Conection Steel Structure Steel Design

Purlins Pascal Steel Buildings

What Is A Purlin Everything You Must Know Before Buying It S

Load Table Prosigma Single Span Purlins Duggan Steel Group

What Is A Purlin Everything You Must Know Before Buying It S

0 comments:

Post a Comment