Do not weld in locations near degreasing cleaning or spraying op-erations. Electric resistance welding is widely used for example in manufacture of.

Schematic Figure Of Resistance Spot Welding Process Download Scientific Diagram

What is a resistance welding control.

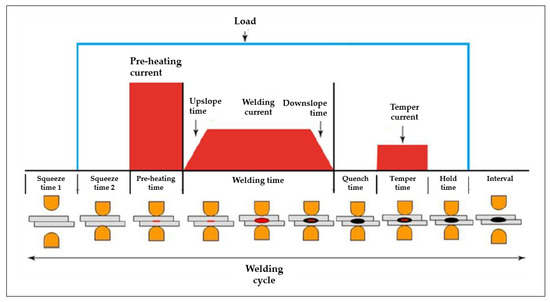

Resistance welding force control. RESISTANCE WELDING Also refer to RWMA Bulletin 5 Resistance Welding Control Standards See References Page 62 Resistance welding is one of the simplest lowest cost surest means of metal joining. The parameters that are used to develop a spot weld are the welding current weld time and electrode force. However the quality of resistance spot welding RSW on galvanized steels was sensitive to variable electrode force.

The amount of heat produced depends on the resistance of the material surface conditions a current supplied time duration of current supplied etc. The electrode force affects the heat generation by controlling the resistance during the welding process. 513 ELECTRODES The composition of electrodes shall conform to the Resistance Welder Manufacturers.

Resistance welding is the method used to join two plain metal work pieces together by running an electrical current through them. The welding head shall be of low-inertia design and provide a means of efficiently controlling electrode force. Electric resistance welding ERW is a welding process where metal parts in contact are permanently joined by heating them with an electric current melting the metal at the joint.

Inverter assemblies ranging from 50 amps to 8000 amps are available to meet any welding application. Electrode force was not used as a control. Resistance Welding AMADA WELD TECH offers a wide range of welding technologies including Linear DC High Frequency Inverter Capacitive Discharge and AC.

The workpieces must be compressed with a certain force at the weld zone to enable the passage of the current. WeldComputer Corporations Inverter Resistance Welding Control provides precise heat control with superior regulation for AC or MFDC Three Phase Full Wave Three Phase Half-Wave or Frequency Converter resistance welding applications. Do not weld on coated metals such as galvanized lead or.

In fact the purpose of a welding control is to coordinate the application of. The thermal constant K can be affected by part geometry fixturing and weld force. Ad Find China Manufacturers Of Welding Wire.

The electrode force shall be repeatable to within 5. It may be concluded from the preceding paragraphs that it is important to apply the welding current at the proper time during the operation of the welding machine. Considering controlling electrode force exactly with servo guns a design of.

The resistance of the workpieces R is a function of the weld force and the materials used. Resistance Spot Welding RSW is a process that is widely used in the automotive industries. High quality welded joints are obtained by coordinating welding current.

An understanding of the resistance welding process is basic to making good welds. The weld current I and duration of current t are controlled by the resistance welding power supply. Micro resistance welding is effective way to reliably join small-scale parts in electronics industry and instrument-making.

During the squeeze cycle the electrode force which is used to bring the metal sheets into contact influences the contact. This is the function of the welding control. The heat and rays of the arc can react with vapors to form highly toxic and irritating gases.

When a current passes through an electric resistance it produces heat. This is the same principle which is used in the electric coil. Welding pressure is produced by the force exerted on the jo int by the electrodes.

Welding fumes and gases can displace air and lower the oxygen level causing injury or death. Resistance Welding Working Principle Diagram Process. The bulk and contact resistance values of the workpieces electrodes and their interfaces both cause and affect the amount.

The necessary welding heat is generated by the electrical resistance of the metals by the contact resistance in between them and by the electrical current. The welding force influences the resistance welding process by its effect on the contact resistance at the interfaces and on the contact area due to deformation of materials. Electrode force is considered to be the net dynamic force of the electrodes upon the work and it is the resultant pressure produced by this force that affects the contact resistance.

Resistance Ω and t weld time cycles 1 cycles 20 ms for a 50 Hz spot welding machine. We have over 100 years of experience in resistance welding which has enabled us to develop a versatile range that offers revolutionary designs for optimum and constant welding performance. As the pressure is increased the contact resistance and the heat generated at.

Ad Find China Manufacturers Of Welding Wire. Be sure the breathing air is safe.

Drag Force Equation In Aerodynamics Mechanical Engineering Aerodynamics Mechanical Engineering Lift Force

Resistance Welding Software For Simulation And Optimization Of Spot Projection Butt And Micro Welding

Qj57 Dc Resistancebridge Measure The Actual Resistance Of Metal Bars Sheets Or Cables And Wires Inspect The Welding Quality Of Resistance Metal Bar Bridge

Metals Free Full Text Optimization Of The Resistance Spot Welding Process Of 22mnb5 Galvannealed Steel Using Response Surface Methodology And Global Criterion Method Based On Principal Components Analysis Html

A Tutorial On Battery Pack Assembly Electricbike Com Battery Pack Car Starter Battery

100 Amp Welding Machine How To Make Welding Machine At Home Diy Welding Machine Welding Welding Table

Resistance Projection Welding Working Of Resistance Projection Welding

Resistance Spot Welding 26 Download Scientific Diagram

Welding Seamer Is A Special Purpose Welding Machine Used For Longitudinal Welding Of Stainless Steel Vessels Seamer Having Maquinas E Ferramentas Ferramentas

0 comments:

Post a Comment