The electrode force shall be repeatable to within 5. It includes a welding head used to hold the metal among its electrodes applies a welding power supply force to welding the metal.

Welding News Resistance Welding

Resistance Spot Welding of High Contact-Resistance Surfaces for Weldbonding Expulsion-free Class A welds can be obtained for high surface-resistance aluminum alloys by using appropri ate welding schedules BYK.

Resistance welding force. Gauges maintain an accuracy of 2 for 30 to 90 of the gauges range. The thermal constant K can be affected by part geometry fixturing and weld force. 160 mm thick bare 7075-T6 aluminum sheet.

Our Digital-Electronic DLC Series gauge supplies the highest accuracy 05 for 95 of the gauges range. The resistance of the workpieces R is a function of the weld force and the materials used. It works by passing an electrical current through the parts for a precisely controlled time and under a controlled pressure also called the force.

Resistance welding is one of the oldest of the electric welding process is used by industry today. The third critical factor in resistance welding is the force squeezing the metal parts together Electrode Force. Large force may decrease the overall dynamic resistance and increase the nugget growth at high speed.

The welding head shall be of low-inertia design and provide a means of efficiently controlling electrode force. The major portion of this work was conducted on 0063 in. They employed the dynamic resistance profile to analyze the effect of the electrode force.

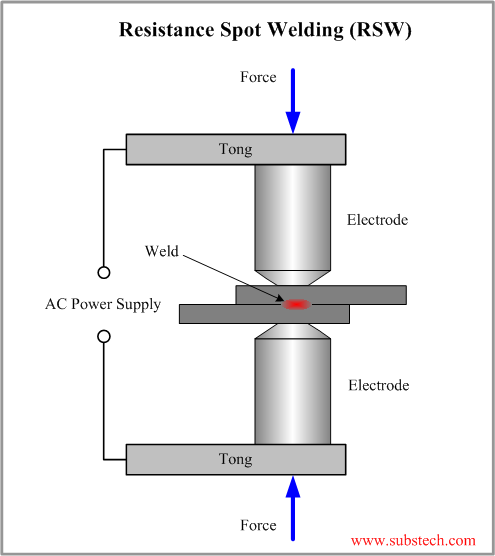

Are worked on the same principle of heat generation due to electric resistance. Resistance welding is the joining of metals by applying pressure and passing current for a length of time through the metal area which is to be joined. Do not weld on coated metals such as galvanized lead or.

Welding fumes and gases can displace air and lower the oxygen level causing injury or death. This force is necessary to assure good electrical contact between the parts being welded and to hold the parts steady until the molten metal forming the welded joint has time to solidify. The workpieces must be compressed with a certain force at the weld zone to enable the passage of the current.

Examples of resistance welding include spot welding induction welding and flash welding. A vehicle has on average 2000 5000 welding spots. All resistance welding spot welding seam welding projection welding etc.

The gauge has large LCD readouts with peak-hold capabilities. Thus this is all about the resistance welding process which is used for welding two metals. The peak-hold feature allows for reading variable forces which are common in resistance welding machinery.

If the resistance welding force is increased will the mechanical properties and the nugget diameter of the weld change. The weld is made by the combination of the heat pressure and time. The key advantage of resistance welding is that no other materials are needed to create the bond which makes this process extremely cost effective.

Resistance Welding Working Principle Diagram Process. The most common type is spot welding. What is Resistance Welding.

When the force is applied the resistance produces heat then resistance welding. The welding force influences the resistance welding process by its effect on the contact resistance at the interfaces and on the contact area due to deformation of materials. The heat and rays of the arc can react with vapors to form highly toxic and irritating gases.

513 ELECTRODES The composition of electrodes shall conform to the Resistance Welder Manufacturers. It can be ex- plained by the fact that the RSW pr ocess is highly efficient and can be automatised. Be sure the breathing air is safe.

Resistance welding is a thermo-electric process in which heat is generated at the interface of the parts to be joined. Resistance welding is a group of welding processes in which coalescence is produced by the heat obtained from resistance of the work to the flow of electric current in a circuit and by the application of pressure 4. Do not weld in locations near degreasing cleaning or spraying op-erations.

Kang Zhouand and Lilong Cai 7 tested effect of electrode force on resistance spot welding process. Resistance spot welding RSW is one of the dominating welding processes in automotive production.

Resistance Welding An Overview Sciencedirect Topics

Resistance Welding Rw Substech

Resistance Spot Welding System Download Scientific Diagram

Resistance Spot Welding Cycle F Is The Forging Force And I Is The Download Scientific Diagram

Figure 1 2 From Optimization Of Process Parameters For Resistance Spot Welding Process Of Austenitic Ss 304 Using Response Surface Method A Review Semantic Scholar

Gauges And Meters For Resistance Welding G E Schmidt

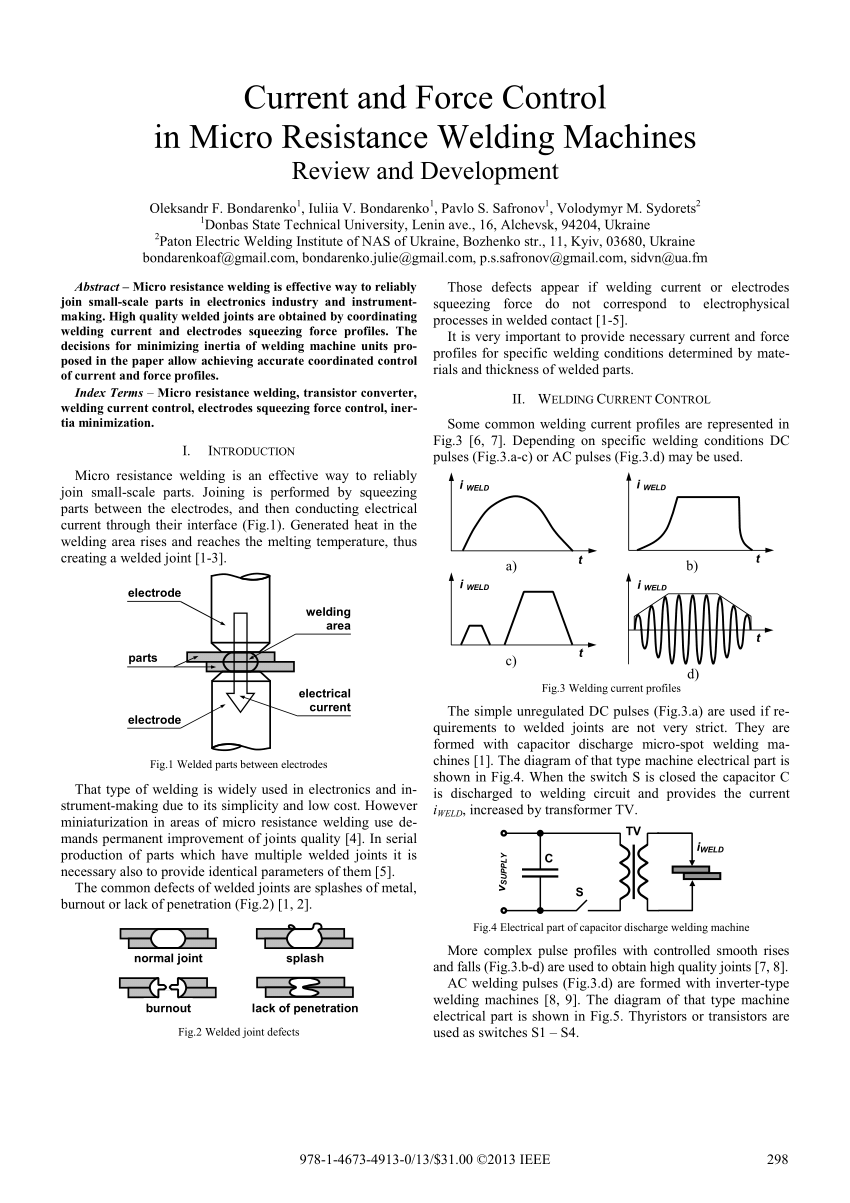

Pdf Current And Force Control In Micro Resistance Welding Machines Review And Development

0 comments:

Post a Comment