Piping must be installed. The amount of heat needing to be applied will vary but well deal with that in the next step.

How To Solder Copper Pipes The Home Depot

This way the pipe will heat up in about 30 seconds and with flux you will find soldering copper pipe.

Soldering copper pipe method statement. Install piping to be as short and direct as possible with a minimum number of joints elbows and fittings. The Copper Development Association created the Soldering Procedure Specification in response to the many inquiries regarding the methods and procedures for qualifying installers of soldered copper piping systems. Ensure that the pipe heats the.

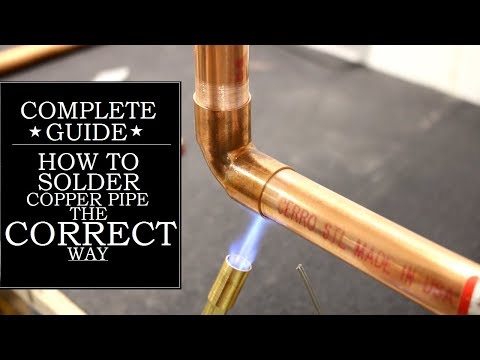

This video will explain to you in details how to solder copper the CORRECT way so you can do it yourself and not have to pay an expensive plumber and save TO. As you could see there are no more surface spottings and thats exactly what we are looking for. Brazing Of Copper Pipe METHOD STATEMENT 1.

Most Solder melts at 324 degrees Fahrenheit. All Health Safety rules must be obeyed. Using a brush an adequate but not excessive amount of flux is applied to the outside of the tube and the inside of the fitting socket.

Below is a brief method statement for copper pipe installation and brazing for any kind of project. Soldering the Copper Pipe When you are ready to begin soldering the pipe get the blow torch as hot as possible before you apply it to the pipe. Contact customers management to gain permission and to advise of work to be carried out.

It gives details of how to carry out the work and what health and safety issues and controls are necessary. How to Solder or sweat to connect copper pipes for water supply lines. 110v impact wrenches 110V corded.

Flaring or swaging joints. Below is list of mandatory tools and equipments that are useful for this activity. You cant use a soldering iron here.

SCOPE This procedure is applicable for the soldering of copper tube and copper alloy fittings in the range of 0375 nominal to 80 nominal. Soldering copper pipe requires a relatively large amount of high intensity heat which is why a propane torch is typically used to heat the joint. I confirm our acceptance of this Risk Assessment Method Statement and that we will undertake our responsibilities as listed on Page 2.

This will also serve as guideline for newly hired employee which will be dealing with. The heat should be applied as evenly as possible around the fitting. Next is the fitting.

The purpose of this method statement is to establish a standard procedure for the proper cutting and jointing of copper pipe by using the right tools and procedure ie. M-0008 refer to the attached manufacturer recommendation for the installation of the Copper tupe and solder joints. Where required complete Hot Work Permit and adhere to any rules printed thereon over and above these procedures.

Method Statement For Copper Pipe Cutting Jointing. Soldering Procedure Specification CDA-2001 for Soldering Copper and Copper Alloy Tube and Fittings Using a Manual Air-fuel Torch and ASTM B 828 Procedures. Adjust pipe work as required and connect to new calorifier as per manufactures instructions.

This plumbing method of statement covers the installation of domestic water system piping and accessories. How To Video demonstrating how to solder copper pipe. The procedure defines the method to ensure the installation work as per contract requirements specifications and best practices.

The best way to proceed with the solder is to heat up the pipe as quickly as possible. Tool box for MechanicalHand Tools. The first step to accomplish this is to clean both parts thatll be joined together.

110v reciprocating saw Soldering equipment for brazing of copper pipework. Wall thickness range shall be from 0023. To obtain this temperature the cone in the center of a cheap propane torch needs to be 15 inches in height.

HOW TO SOLDER COPPER PIPE FITTINGS WITHOUT SNOT - My plumber methods - YouTube. This video describes how to tin copper and the sheet youd like to solder. Also shown simplified methods of cleaning copper pipe and fittingsAlso see the video.

While there is currently no formalized installer certification program the procedure detailed in the. To connect copper tubing and pipe one of the best methods is to use solder and a. It goes through cleaning marking flux and solder.

Copper Pipe Soldering Method The inside of the fitting socket and the outside of the tube is cleaned with a cleaning pad fine sand paper or steel wool. To clean the pipe take your sand paper and sand the portion thatll penetrate the fitting until it resembles this. It shows how to create a lap s.

How To Solder Copper Pipes The Home Depot

How To Solder Copper Pipe 8 Steps With Pictures Instructables

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

Method Of Statement For Installation Of Domestic Hot Cold Water Supply Copper Piping Method Statement Hq

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Solder Copper Pipes The Home Depot

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Solder Copper Pipe 8 Steps With Pictures Instructables

0 comments:

Post a Comment