Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier. The main area of the gasless MIG welders application is the connection of soft and non-ferrous metals such as aluminum.

Gasless Mig Welding What Is Gassless Mig Welding Dynaweld

Jun 26 2014.

Welding aluminium gasless mig. The output capacity of your welder determines the thickness you can weld. The electrodes for welding aluminum. If you want to weld thin metal aluminum or perform auto body work gas MIG welding is better.

Consider material thickness. Strange as it may seem this is not necessarily the case. The gun and wire are dragged away from the weld bead.

And MIG and TIG uses an electrical arc to melt the base metals and the filler material. DC doesnt work for aluminum welding - well not unless you have a very hi-tech welding machine at work we had a. You dont want to grind the aluminum with a grinding disk made for steel or stainless.

Before you can mig weld aluminum make sure you have a machine with an output greater than 200 amps and a shielding gas of pure argon. For welding thicker metal that contains dirt rust paint etc gasless MIG welding is a good option. Simultaneously the idea of a gasless procedure has a fair share of appeal to the industry.

The aluminum cannot be MIG welded without the protective layer being removed first. Wire is a MIG welding process that relies on a continuous tubular wire feed. The correct term is GMAW Gas Metal Arc Welding since shielding gases can be both inert as argon reactive as CO² or both as C-25.

Can be used outdoors or in windy conditions. To MIG weld aluminum thinner than 14 gauge 074 inch it may be necessary to use specialized pulsed MIG or AC TIG welding equipment. Well welcome to Weld Talk.

The TecArc spool guns are good in the respect that they have their own in-line control box so no need to fit a PCB inside the welder. Some of the pros of gasless MIG welders include. The obvious apply but the cleaning methods change.

Fortunately removing the oxidizing layer is a pretty straightforward procedure. When it comes to MIG welding aluminum joint preparation is a must. This video shows the difference between using the right and wrong technique when welding with gasless MIG wire.

You can choose aluminum to MIG weld with Self-Shielded Flux-Cored Arc Welding FCAW-S wires. But I think you would still need an AC power supply. When you welding with a gasless MIG wire you DO NOT NEED the shroud to be on.

Aluminum melts at 1220 degrees Fahrenheit but the protective oxidized layer at the surface of the aluminum doesnt melt until 3700 degrees Fahrenheit. Additionally youll want to use aluminum electrodes since electrode thickness is critical with aluminum. Gasless wire welding was originally designed as a replacement for stick welding mostly for use out-side where protecting gas-es could be blown away by the wind and higher pro-ductivity was necessary.

Heres why 09mm rather than 08mm may actually be your best choice for thinner materials. The arc and heat are concentrated on the weld pool the base metal receives more heat deeper melting more penetration and the weld profile is higher with more. Aluminum MIG Welding Spool Gun Miller Aluminum MIG Welding Spool Gun How to Preparation the Joint for MIG Welding Aluminum.

MIG is an acronym for metal inert gas which is really wrong also. Jan 23 2018. The weld pool has to be protected from the oxygen in the air and this is done by displacing the air with gas.

The acronym MIG stands for Metal Inert Gas. Its the flux that causes all the weld spatter in the photo and the light coloured crust slag on top of the weld. Theres no such thing as gasless mig welding.

The shroud is a consumable as too are the contact tip and the MIG wire and even the tip holdergas diffuser are welding. Self Shielding Mig Wire is a tube of metal with a flux core. You can get aluminium welding electrode for stick welders so I dont see why you shouldnt be able to get a flux core electrode.

Welding Aluminum Without Flux Core Wire. Might as well start off right - there is no such thing as a gasless MIG. Both MIG and TIG welding uses electricity and Argon shielding gas to protect the joint from the air.

So that they all merge and flow together and that forms your weld. The filler metal for the weld. A MIG welding gun has a nozzle or a shroud which is only needed when you use a shielding gas.

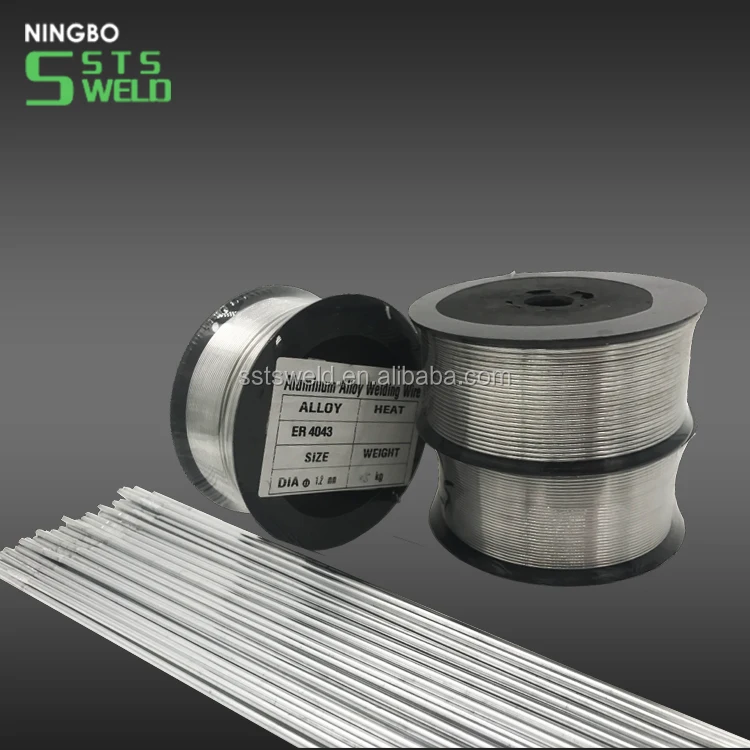

MIG Or TIG Welding Aluminum. The no gas MIG welders are also known as the flux core wire welders. Ideally for hassle free alu welding you want a pushpull gun or a Spool gun.

They are not cheap though so unless intending to do a lot of Alu welding then the easiest method is just get a teflon. Where ordinary mild steel mig welding wire needs an inert gas shield to prevent it from oxidising when melted gasless MIG wire has a flux core which forms the shield around the weld to keep oxygen out. When it comes to MIG welding thinner sections with gasless welding wire - for example 16mm sheet or RHStube - many welders logically assume that when it comes to choice of wire size 08mm wire will be better than 09mm.

The argon or helium could be used as a gas for MIG welders. Does it mean that one can MIG weld aluminum and a shielding gas is optional. So called Gasless Mig Wire is actually Self Shielding.

200a Aluminium Berdenyut Mig Wire Tukang Las Gasless Solodar Mig Tig Mesin Las Mma Buy Aluminium Inti Fluks Alat Mig Wire Alat Pulse Mig Wire Tukang Las Product On Alibaba Com

Gasless Aluminum Welding Wire Gasless Aluminum Welding Wire Suppliers And Manufacturers At Alibaba Com

2 5m Gasless Mig Welder Las Gun Untuk Mid Baja Aluminium Dan Stainless Steel Welding Torch Mig Welding Gunmig Gun Aliexpress

2 5m Gasless Mig Welder Las Gun Untuk Mid Baja Aluminium Dan Stainless Steel Welding Torch Mig Welding Gunmig Gun Aliexpress

Jual 1 Roll 1kg Stainless Steel Gasless Mig Welding Wires 08mm Flux Jakarta Pusat Nur Dream Tokopedia

Gasless Mig Welding What Causes Porosity And How To Fix It

2 5m Gasless Mig Welder Las Gun Untuk Mid Baja Aluminium Dan Stainless Steel Welding Torch Mig Welding Gunmig Gun Aliexpress

Mig Welding Aluminum Stick Out Youtube

0 comments:

Post a Comment