Preheat the entire part. Too little flame can be lead to a fragile weld.

Model T Ford Forum Cast Iron Oxy Acet Welding

The heating flame should be trimmed to give a large access of acetylene so that the cone has a length of 50 to 75mm 2 to 3in before cutting oxygen is turned on.

Welding cast iron oxy acetylene. Oxy-Acetylene Rods Brazing. As a result it produces a stronger and more durable weld. First you have to adjust the oxy-acetylene flame per the surface requirements.

It easily maintains the temperature of components and other wonderful options to weld cast iron. This head has a broken fin. This type of welding is performed using the following steps.

Oxy-Acetylene Rods Steel. Oxy-Acetylene Welding of Cast Iron. Note how the color is exactly the same as the base material.

Brazing isnt really welding as it doesnt fuse the metal as a weld does. Use the cast iron rods that are actually cast iron. Use of a gas flame to heat the casting to its melting point is time consuming and can lead to surface oxidation but the high preheat of the base metal and the low cooling rate which results ensure that formation of hard phases such as martensite in the HAZ.

Because unappropriated steps can give it more cracks in the pieces. Oxy-Acetylene Welding Hot Welding Oxy-acetylene welding is a type of welding used for smaller parts that can be heated wiht the torch referred to as gas welding. Once you try to curtail the extreme heat and quick cooling of the electric welding process then oxy-acetylene is the option.

Care must be taken not to oxidise the cast iron during acetylene welding as this causes silicon loss and the formation of white iron in the weld. However the arc is generator not by the current but by the energy provided by the oxy-acetylene torch. Stick welding is the alternative method for welding cast iron where the electrode with flux is used.

But in welding cast iron its a step you shouldnt take. Using the right temperature stated above is vital to. The machining is required after we complete this process.

Stick welding is a complex welding method. Only high pressure dissolved acetylene can be used for cutting cast iron. Oxy-Acetylene or Oxygen Acetylene welding is a type of welding that relies on the combustion of oxygen and acetylene gases hence often referred to as gas welding.

Oxyacetylene welding is one of the most well established methods of joining cast iron. Oxy-Acetylene welding requires a specific skill set and thorough practice coupled with which it can be used to weld virtually any metal. This is after the Fusion Welding and shows the weld rough ground to conform to the original casting.

Oxy-Acetylene Rods Cast Iron. To weld cast iron stick welding is the preferred method and you dont need any Oxy acetylene torch for it. Oxy acetylene welding also makes use of electrodes but instead of an arc generated by current an oxy acetylene torch provides the energy for welding.

Oxy-acetylene welding has my vote. Oxy-acetylene welding is another option frequently used to weld cast iron. Such a flame however is quite suitable for welding high carbon steel and cast iron.

The head is all finished. Oxy-acetylene welding of cast iron is comparatively easy if attention is paid to some simple rules. The welding rod should be melted in the molten weld.

So its important to understand the reality and the difficulty to adopt stick welding to weld cast iron. The head is pre-heated to approximately 1800 degrees where it was Fusion Welded using Oxy-Acetylene and bare cast iron rod. Oxy-Acetylene Rods Aluminium.

Its a form of arc welding. Cooling surfaces around the intended join point limits your cast iron cohesive nature. In oxy acetylene welding you also use an electrode.

It contains two kinds of carbon combined and graphitic. The cast iron in common use is known as gray it is quite soft easily machined and has a lower melting point than wrought iron or steel. It is one of the most versatile types of welding.

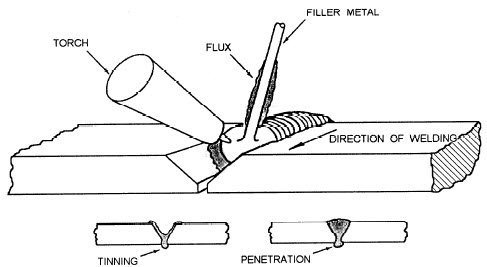

Cast Iron Apply the technique shown in Fig12. This kind of welding makes use of electric arc current which forms when an oxy torch and electrode come in contact. Cast iron electrodes and copper zinc electrodes are both suitable for oxy acetylene welding of cast iron.

Stick welding is one of the most common and dominating welding processes to weld cast iron. You can choose either cast iron or copper zinc electrodes for welding cast iron using this technique. Structurally it consists of two parts namely the inner cone and the outer envelope as shown in Fig.

What Is Oxy-Acetylene Welding. What Is Stick Welding. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

A new fin was fabricated from cast iron and put into position for welding. Ive used the oven in the kitchen didnt get any for a week after that little stunt but the weld works just fine. The neutral flame has nearly one-to-one ratio of acetylene and oxygen by volume.

How To Weld Cast Iron Welder Portal

Gas Welding How To Gas Weld Cast Iron With A Cobra Torch From Eastwood Youtube

Cast Iron Gas Welding Using Cast Iron Filler Rod Youtube

Cast Iron Oxy Acetylene Welding Rod Gas Welding Accessories Amazon Com

1kg Murni Nikel Las Cast Iron Rod Besi Cor Nikel Besi Elektroda Nikel Tembaga Las Cast Iron Rod Welding Rod Rod Weldnickel Electrodes Aliexpress

Cast Iron Repair Oxy Acetylene Welding Youtube

First Time Using Oxy Acetylene Torch To Weld Welding

Model T Ford Forum Cast Iron Oxy Acet Welding

0 comments:

Post a Comment