Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding.

Welding Technology Welding Construction

The repairs may be made in the foundry where the castings are produced or may be made to repair casting defects that are discovered after the part is machined.

Welding casting meaning. In casting the metal is heated sufficiently to make it into liquid and then poured into moulds of desired shapes. Welders performance qualification ensures that the qualified welders using approved welding procedures are capable of developing the minimum requirement specified for acceptable weldment. A casting mold as defined in claim 1 wherein the closing means is provided with fireproof material at.

Until the beginnings of the 20th century welding was done via a process known as forge. Joining processes include welding soldering brazing and adhesive bonding. Arc welding makes use of an electrical current.

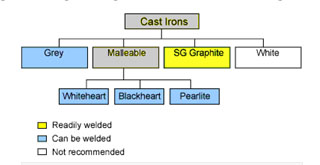

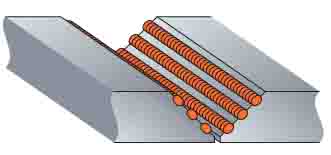

In a multipass weld this cast structure may be modified depending on the particular metal that is being welded. Welding is usually used on metals and thermoplastics but can also be used on wood. After solidification take the casting out by breaking the mold called a casting process.

Welding Operator One who operates adaptive control automatic mechanized or robotic welding equipment. Welding Procedure The detailed methods and practices involved in the production of. It can be done using different energy sources from a gas flame or electric arc to a laser or ultrasound.

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. However die castings are very different. Welding Power Source An apparatus for supplying current and voltage suitable for welding.

Sand castings investment castings and permanent mold castings are usually very weldable because molten aluminum is cast into a mold that is a relatively poor thermal conductor so the casting solidifies slowly. When a permanent join is required welding is commonly used. Welding is the least expensive process and widely used now a days in fabrication.

Welding processes are frequently used in. Welding joints different metals with the help of a number of processes in which heat is supplied either electrically or by mean of a gas torch. The welding process is a fabrication process that joins materials usually metals or thermoplastics by causing coalescence.

Welding procedure qualification record PQR is a record of welding data used to weld a test coupon and includes variables recorded during welding as also the results of various tests carried out. Casting is a process in which the molten metal is poured into the casting cavity and it is allowed for solidification. After the arc passes rapid cooling of the weld metal occurs.

A casting mold as defined in claim 1 wherein said closing means is fabricated from a ferrous metal. Various machining operations are turning drilling and milling. Handling and even packaging.

Welding is the process of joining metals by melting the parts and then using a filler to form a joint. This means that any dissolved gases in the molten aluminum have a chance to percolate out. A one-pass weld has a cast structure with columnar grains extending from the edge of the molten pool to the centre of the weld.

The completed welded joint may be. In most cases welding on cast iron involves repairs to castings not joining casting to other members. Manufacturing nearly any modern product involves joining various separate components.

Introduction Welding is a process of joining two metal pieces by the application of heat.

Why Can T Cast Iron Be Welded Quora

How To Weld Cast Iron Metal Casting Blog

Which Is Stronger Forging Or Casting Workshop Welding

Cast Iron Welding Basic Procedures Weld Guru

Welding Technology Welding Construction

Welding Cast Iron The How To Guide

Welding General Welding Requirements Of O Let Fittings Like Weldolet Sockolet Thredolet Elbolet Nipolet Latrolet Sweepolet Fittings

A Z Of Welding Terms Welding Glossary Westermans Blog

Cast Iron Welding Basic Procedures Weld Guru

0 comments:

Post a Comment