2 What is the maximum qualified deposited weld metal thiciness in WPS. Hence you may get 1.

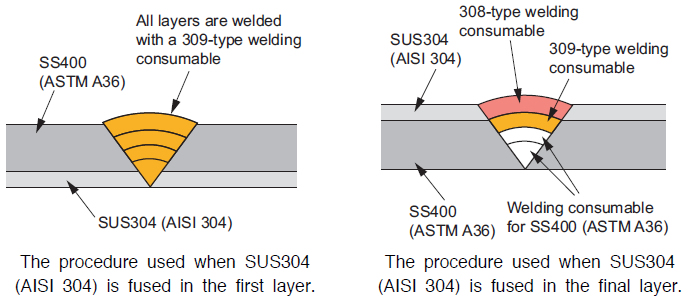

Welding Of Medium High Carbon Steels And Special Steels Education Center Kobelco Kobe Steel Ltd

Best Regards Mohit Aggarwal.

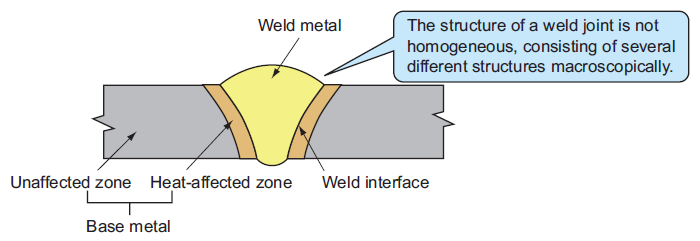

Welding deposited metal thickness. The metal arc welding process uses an electric arc to generate heat to melt the parent material in the joint. A standard magnetic sensor of weld deposit thickness for a certain but constant amount of ferrite in the weld deposit metal. You should also use the push welding technique when you weld thick metal 316 of an inch or greater.

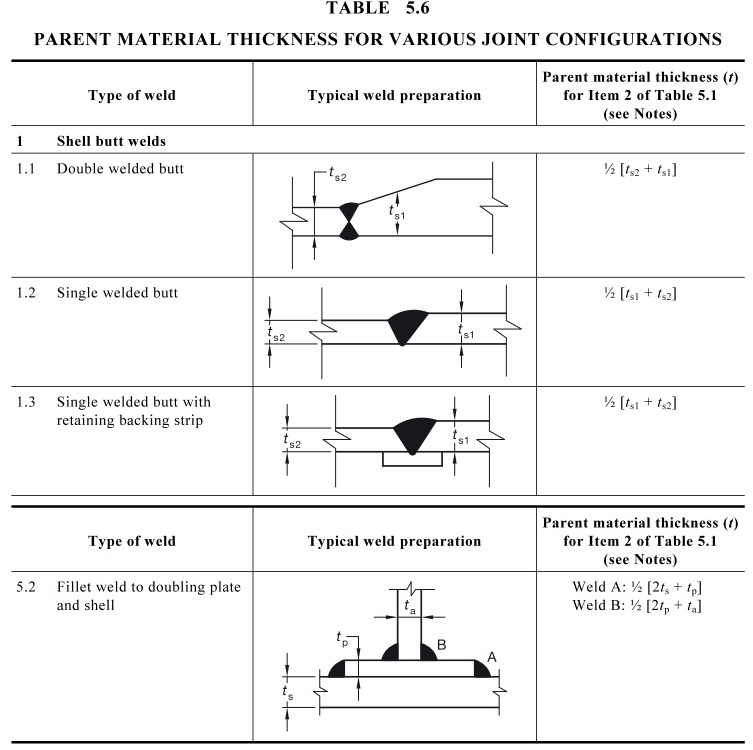

If the joint is made of more than one welding process then the maximum deposited thickness each process in the above example is 2 x Deposited Weld Metal t - GTAW 12mm and SMAW 52mm This is because t T for this process as t 191mm QW4511. Correct prescription of metallurgical requirements and sound practical application is a prerequisite for successful fusion welds. Assuming for a single welding process the qualified weld metal deposited thickness range is 116 up to 2t.

The Type of Gas You Use. When qualifying a WPS we have 2 thicknesses to deal with potentially. Some welders say 18 of inch or more.

There is no restriction on minimum weld deposit thickness limit as per table QW-4521 b Weld metal thickness limit is only applicable for welder performing manual and semi-automatic welding and not applicable for Welding operator performing automatic or machine welding. ER70S-3 or ER4043 are used for any type of welding. If the welder qualifies WPS over 150mm thickness of the test piece it means the welder qualify for a minimum thickness of 5mm and maximum thickness 133T and their maximum deposited weld metal thickness shall be 133t when deposited weld metal thickness greater than equal to.

0030-inch diameter is the most commonly used wire due to its versatility dealing with various thickness of metals. Deposited Weld metal thickness. A method of metal arc welding on pieces 34 in.

Base Metal approval range for the above welded joint is 476mm To 52mm Ref QW4511. Qualified deposited weld metal thickness is 2 X the dwmt of each process. Welding is a complex interaction of physical and chemical science.

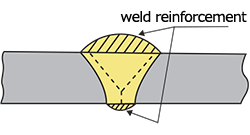

The thickness of the base metal which will determine the thickness the procedure can be qualified for QW-450 and the thickness of the deposited weld metal. Considering all above factors the total thickness of the weld metal could be 711 plate 1 to 150 mm root 150 to 200 mm reinforcement 950 to 1050 mm and not 711 mm as you assume. Weld 316 Inch Metal Or More.

2 has measured on a pure austenite after austenite annealing the weld de posit thickness within 02 mm whereas on thermally non-. 5-200mm or 5-40 mm. Root with 240 mm thick filler rod.

Consequently no limitations are specified for the range of base metal thickness qualified by a particular qualification test weld. ER70S-6 is used for welding on steel that have not been cleaned out rusty or dirty. For the low voltage shortcircuiting type of gas metalarc process when the deposited weld metals thickness is less than 13 mm and an increase in deposited weld metals thickness beyond 11 times that of the qualifications test deposited weld metal thickness.

ASME IX does not consider base metal thickness to be an essential variable for welding performance qualification using any of the listed welding processes. If a welder deposits weld metal of thickness 13 mm or more with a minimum of three layers then heshe qualifies for an unlimited thickness but the maximum thickness which the welder can weld shall not. If you are using more than one process the amount of weld metal deposited with each process comes into play.

The Maximum Thickness t of Deposited Weld Metal Qualified is 8 mm for GTAW. If you are welding steel plate that is more than 316 of an inch you should bevel the edges in order to get proper penetration and therefore create a good weld at the joint. It is my interpretation that this PQR can then be used to write a WPS.

There are no criteria for minimum thickness. Thickness limits are specified for deposited weld metal. Deposited weld metal thickness is the thickness you deposit with a particular welding process and according to code limitations deposit thickness depend upon base metal thickness thickness of weld metal you deposit with particular process and industries have to follow code and standards.

As steel plate becomes thicker as shapes become heavier and as assemblies become more restrained construction problems are more likely. 19 mm thick or heavier in which the weld metal is deposited in layers composed of strings of beads applied directly to the face of the bevel. You must measure the thickness of deposited weld metal for the GTAW process and the remainder is the deposited weld metal thickness for the SMAW process.

1 What is the qualified thickness range for base metal in WPS. After reviewing the background and history of welding on thick restrained steel this paper explains that there are four categories of challenges that. For instance the sensor shown in fig.

ASME IX is used for the welding procedure qualification. Welding heavy structural steel entails certain challenges. If you plan to weld thin metals use a 0023-inch wire.

Welding References Education Center Kobelco Kobe Steel Ltd

Welding Of Stainless Steel Education Center Kobelco Kobe Steel Ltd

Arc Welding Amperage Settings According To Electrode Size And Metal Thickness Arc Welding Welding Metal Working

In Making A Mig Wire Purchase Your Last Decision Involves The Quantity Of Wire And How It 39 S Housed For Instance Lin Welding Mig Welding Mig Welding Wire

Bagian Bagian Lasan Butt Weld Fillet Weld Dan Penjelasannya

Electrode Meaning Specification And Uses Metallurgy Welding Electrodes Meant To Be Electrodes

The Base Metal Thickness Essential Variable For Welding Procedures Is Explored

Tensile Test A All Weld Metal In Longitudinal Direction B Dimension Download Scientific Diagram

Materials Welding Re Mw 29863 Asme Section Ix Thickness Range Qualification

0 comments:

Post a Comment