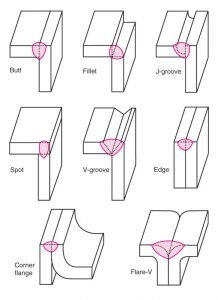

Groove is one of the most common welds you will come across in your welding career. You do not need to prepare the edge and this type of joint make it easy to weld piping systems.

Sambungan Las Jenis Kampuh Las Gambar Dan Penjelasannya Pengelasan Net

Its a great joint to start with when you begin welding.

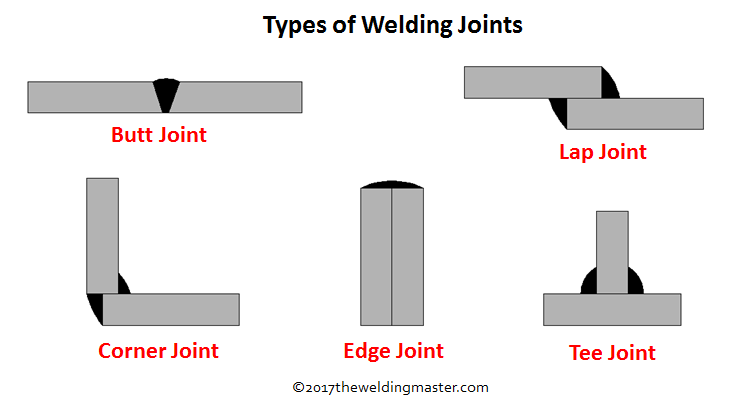

Welding l joint. It is often used to weld edge-to-edge joints but that is not where its use ends. Let l length of weld t Depth of weld FTensile force σt Allowable tensile stress The tensile force F σt x A σt x l x t. Similar to the tee joint the corner joint forms an L-shape.

Throat of a combination partial joint penetration groove weld and a fillet weld shall be the shortest distance from the joint root to the weld face of the diagrammatic weld minus 18 in. Scott shows off the Five Basic Welding Joints that fabricators and professionals are known to weld on a regular basis. They are sometimes categorized as modified versions of butt welds.

3 mm for any groove detail requiring such deduction see Figure 33 and Annex I. Butt welds are more expensive than fillet welds. It is widely used in the combined electron beam laser beam and resistance spot welding.

Fillet Welded Joints are the most common type of welding joint and accounts for nearly 75 of joints made with arc welding. Welds can be made on one or both sides. You can use lap joints to patch things or.

For more information please check out. To create a lap joint you must fuse two metal pieces in an overlapping pattern on top of each other. This joint configuration can be used with T joints corner joints joints binding flat and curved.

Best used for welding 12-gauge or thinner sheet metal the flush corner joint design can support only moderate loads. In this welding can be done on both sides of the plates for greater strength. Ad Find China Manufacturers Of Welding Wire.

Fillet Weld T Joint Example. The lap joint welding is applied for welding two metal plates that are different in their thickness. Lap Fillet joint 31 Butt weld joint- If the edges of the two plates are touching each other and are joined by welding then the joint is called butt weld joint 14.

Welding joints can be prepared in numerous. Theres almost nothing else to worry about once theyre positioned in the right place other than simply welding it. Ad Find China Manufacturers Of Welding Wire.

These joints are smooth going to weld. Good weld penetration is often difficult with this type of joint Figure 5 View A. Fillet welds are mostly used in piping systems to join pipe to socket joints.

If you can incorporate these joints into your project it will add extra strength where it may otherwise be lacking. 242 Length 2421 Effective Length Straight. What to know when welding lap joints.

Fillet Weld Lap Joint Example.

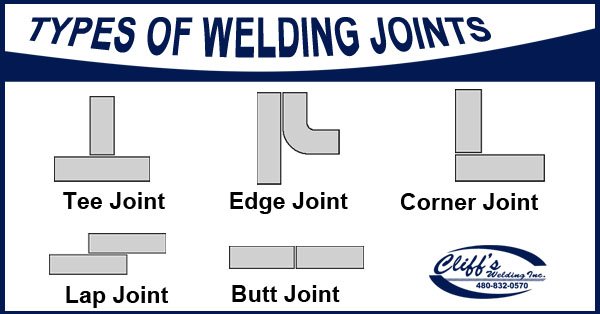

5 Types Of Welding Joints Cliff S Welding Mesa Az 480 832 0570

5 Types Of Welding Joints Cliff S Welding Mesa Az 480 832 0570

5 Types Of Welding Joints And Their Use 2020 Complete Guide

The 5 Types Of Welding Joints Rx Mechanic

What Are The 5 Basic Types Of Welding Joints A Beginner S Guide Welders Lab

Types Of Welding Joints Welder Portal

Different Types Of Welding Joints The Welding Master

0 comments:

Post a Comment