If the weld area of a fil-let weld in a hole or slot calculated from this length is greater than. First detected by a loud popping which can stop the welding process in extreme cases.

This crater results from the force of the arc and the contraction of melted metal when it cools and solidifies.

Welding meaning of crater. The crater is a kind of crack which occurs when the welding arc is broken and molten metal is not available to fill the cavity. Causes of the crater. The size of each crater relates directly to the welding current.

It occurs when the crater is not filled before the arc is broken which causes the outer edges to cool faster than the crater. Crater A large Cavity occurs where electrode sparks continuous on a single point. You could probably search the Internet for an.

Use of large electrode. Not to be confused with deformation which results immediately upon application of a stress. This imperfection results from shrinkage on weld pool solidification.

Weld Crater is the unfilled end of a weld. This will fill the weld crater slow the cooling rate fill the undercut and reduce the chances of a crater crack. An undesirable crater at the edge of the weld caused by poor weaving technique or excessive welding speed UPSET.

Most often it is the result of encountering tiny pockets of oxidation inside or on the surface of the metal being welded. Creep The slow deformation for example elongation of a metal under prolonged stress. Crater occurs due to residual stress imposed by.

Crater A depression in the weld face at the termination of a weld bead. The effective length of a curved fillet weld shall be measured along the centerline of the effective throat. Crater pipe causes and prevention during welding.

A localized increase in volume in the region of a weld resulting from the application of pressure. Distortion This occurs were not. Spatter and surface porosity On the welded parts there some drops occur.

To allow for the start or stop crater of the weld. Physical properties generally result in distortion and the heat transfer rates of the base material. What you are describing is a weld crater shrinkage cavity also known as a pipe.

Then welding metallurgy may be defined as the changes that occur in metals as a result of being joined by the welding process. These changes are manifested by changes in mechanical prop-erties. Unless welding is performed with a very low current a concave dip called a crater occurs at the end of a weldment.

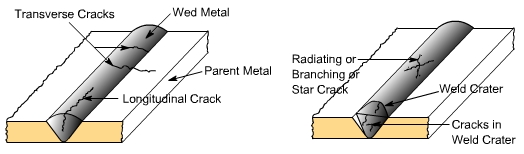

Incomplete filled groove Not filled completely. This causes a stress and then crack is formed. When doing a Restart you want to start at the end of the crack weld back into where the weld stopped and then proceed in the direction you were welding.

The full cross section of weld is not filled and is considered a weld defect. 2422 Effective Length Curved. When extinguishing the arc weld to the desired stop point then back up 1½ times the weld size.

A crater is a tiny explosion which will send droplets of molten metal in every direction. Figure 1 shows an example of a crater shrinkage cavity in the weld crater which was made with a mild steel flux-cored gas-shielded wire. It is not weld porosity but rather is a naturally occurring phenomenon found in arc welding.

Crater - At the end of the weld bead you burn into the steel without depositing any filler metal which leaves a depression in the base metal. A crater pipe forms during the final solidified weld pool and is often associated with some gas porosity. Consequently conditions which exaggerate the liquid to solid volume change will promote its formation.

Incorrect profile Welding is not done properly.

Ppt Defects And Discontinuities Powerpoint Presentation Free Download Id 1764968

7 Most Common Welding Defects Causes And Remedies Slv

Why Welds Crack Welding Answers

Ppt Weld Defects And Discontinuities Powerpoint Presentation Free Download Id 5202897

Unit 5 Welding Process Hareesha N Gowda Lecturer

Common Welding Defects Welders Universe

What Are Weld Craters And Crater Cracks The Graduate Engineer

Electrodes Welding Terms Arc The Flow Of Electrical

0 comments:

Post a Comment