ASME B311-2012 for high pressure steam and other heaing mediums. All draw off points have to be plugged with stopper and shut off main valve to section of pipe to be tested.

Lock the pipe into place using the same feature as the hot plate step and wait 300 for the pipe.

Welding procedure for high pressure pipes. Grind the 6 oclock tack down to clean it up a bit. This includes the diameter and the classification of the electrode. 1 Perform PMI possitive material ID test.

High Pressure Piping BECHT ENGINEERING COMPANY INC. At 200 unlock the Pit Bull remove the hot plate and slide the pipes pipe and fitting together and press so that one bead rolls onto the pipe from each side resembling a pair of lips. Connect pressure gauge to the lower section of pipeline.

I as a CWI has suggested that we perform a technical risk assesment rejected by metallurgistfollowing these stepsconsidering we dont have heat number for this material. End of the pipe. 3 No welding shall be done upon any boiler pressure vessel or pressure piping unless the above requirements respecting procedure tests and pressure welder qualification tests including tests of welding machine procedures and welding.

Start filling in water into pipes by using hand pump. A distinctive feature of welding of high pressure pipes is that welding must be done in several layers of the joint weld. Qualified Positions Groove Fillet.

Gents Ladies. The welding con-sumable should be selected to correctly match or overmatch the strength of the pipe. Go halfway over the tack at 12 oclock and stop.

Start the build up pressure to the alignment pressure level P1 drag pressure maintain the pressure until there are welding seam appear. With the application of welding to pipe fabrication and installation a standard was required. High Pressure Piping -23 Examination Requirements - Other Longitudinal welds 100 RT 100 RT Branch connection 100 RT welds Circumferential 5 Random RT or UT groove welds Metallic Piping Normal High Pressure Neither ultrasonic examination nor in-process.

Table 1 Welding process for different materials Storage Facilities PREPARATION OF PARENT METAL Edge Formation Cleaning Weld Preparation Branch Connections ASSEMBLY FOR WELDING Alignment of Pipes Branches Flanges and Fittings Tack Welding WORKMANSHIP Striking the Arc Slag Removal and Inter Run Inspection. Preheat your electrode on the 6 oclock tack again. Start welding again from the 9 oclock position you dont need to pause for too long this time until the 12 oclock position using that same whipping motion from before.

Qualiicaion and producion welding requirements on high pressure piping HPP systems. ASME B313 Process Piping Course 17. Welding the Root Pass Before beginning to weld the pipe the procedure should be checked to assure that the correct electrode is being used.

ANSIIIAR2-2008 with addendums A and B and ASME B315-2013 for ammonia refrigeraion. The following procedure to be adopted on site for Pressure testing. ASME BPE-2012 for bioprocess.

Unless specifically required otherwise by the welding variables QW-250 a qualification in any position qualifies the procedure for all positions. It may vary from 2 to 10. The standard qual-ifications for welding procedures made in accordance with the ANSIASME Boiler and Pressure Vessel Code and the ANSIASME B31 Codes for Pressure Piping to ensure competent workmanship are the generally accepted standards.

To start with the welding process begin with the alignment stage by inserting the heating plate between the two pipe ends moving both pipe ends close together until contact with the heating plate. Ad Find China Manufacturers Of Welding Wire. The Board of High Pressure Piping Systems has adopted ive model codes with Minnesota amendments.

AWS D143 is often used for heavy equipment but welding codes like this can reference other welding codes like ASME section IX for specific needs like hydraulic pressure lines. We are preparing a Hot Tap weld procedure on a SA 106B live 650 pressure 750 deg sched 80 20 line that has operated for 25 years. There are codes for welding earthmoving equipment and we know heavy equipment has high pressure hydraulic lines.

All Positions for Plate or Pipe. The number of layers depends on the characteristics provided by the types of metal pipes and on the metal from which they are made. Once you have taken the three factors outlined above into consideration you will generally be left with three main processes to consider for welding tanks and pressure vessels - GTAW plasma welding and K-TIG.

The welding process and electrodes must be suitable for all positions permitted by the WPS ASME Section IX QW-203. And ASME Secion IX-2013 for welding requirements on all high-pressure piping. Ad Find China Manufacturers Of Welding Wire.

Schematic Illustration Of Sleeve Repair Welding Of A Defective Pipe Download Scientific Diagram

Putn A Cap On This High Pressure Steam So We Can Get Pipeline Welding Underwater Welding Welding Gear

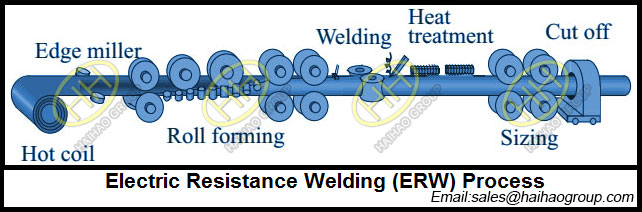

Types And Process Of Welding Pipe Erw Lw Cw Saw Pipes Manufacturing Astm A234 Butt Weld Pipe Fittings A182 Forged Pipe Fittings B16 5 Weld Neck Flange Api 5l Seamless Pipes

What Is Welding Procedure Specification Wps Engineering In 2021 Welding What Is Welding Smaw Welding

0 comments:

Post a Comment