High-strength low-alloy steels include many standard and proprietary grades designed to provide specific desirable combinations of properties such as strength toughness formability weld-ability and atmospheric corrosion resistance. Flat to slightly convex weld beads are preferred.

Discovering The 7018 6013 6011 And 6010 Welding Rod Sizes Chart In 2021 Welding Machine Electric Welding Machine Laser Welding

Ad Supplier of Alloy C263 K500 X - Pipe Plate Sheets Flanges Fittings Tube Round Bar.

Ac is preferred for welding low-alloy steels. For use on aluminum. The assembly by welding of the low-alloyed steels is possible with almost all the arc welding processes and the required equipment are described above in the unalloyed steel section. Thermal cutting of the low alloyed steels can be performed with oxy-fuel process but plasma cutting will be preferred due to reduction of the heat affected zone.

Typically a maximum heat input of 25 KJinch 1 KJmm is preferred. True A push travel angle of 15 degrees-30 degrees is used for welding in the flat position. Low alloy steels contain a few percent typically between 1 and 7 of elements such as Cr Ni Mo and V.

Advantages of AC welding. For example entry-level low cost machines sometimes run only AC power. The latter helps keep the arc ignited as the welding output alternates from positive to negative.

A common event in AC welding is losing the arc. When welding alloys which do not contain ferrite a lower interpass temperature is preferred which lowers thermal stresses. In an AC GTAW power source high frequency must be maintained throughout the welding operation to keep the gases in the arc ionized during the zero points of the AC cycle.

Electrodes used for AC welding can be ground to a taper so that a smaller ball forms on the tip. Developing welding consumables for joining high strength low alloy steels for ship construction6 Ferritic steels have a ductile to brittle transition that is a function of composition and temperature. The assembly by welding of the low-alloyed steels is possible with almost all the arc welding processes and the required equipment are described above in the unalloyed steel section.

Specialist in hard to Locate Alloy C263 K500 X material. Specialist in hard to Locate Alloy C263 K500 X material. Angle electrode 10-15 from 90 Vertical-Up.

AC is not the preferred polarity for most kinds of welding. Alternating Current AC Welding Cons. The best results in most situations come from DC welding.

Because the current fluctuates back and forth the arc needs to restart itself at every turn of the current between positive and negative. Use slight weaving motion within the puddle. Steel 1012 but is still inferior to the fracture toughness of high acicular content steels 13.

Your question leads to a more general discussion of DC vs. Lets see the advantages and disadvantages of ac welding machine. Of course there are a few instances where AC welding would be preferred.

40 rows AI 1742 FC is a seamless copper coated low alloy steel wire. Description and precautions for welding low alloy steels. Thermal cutting of the low alloyed steels can be performed with oxy-fuel process but plasma cutting will be preferred due to reduction of the heat affected zone.

For out of position welding reduce amperages shown by 15. Electrode positive work negative DCEP or AC. It has been proven that increased cooling rate with a high volume fraction of inclusion within the austenite enhances the formation of acicular ferrite in low carbon low alloy steel deposition 1415.

Ad Supplier of Alloy C263 K500 X - Pipe Plate Sheets Flanges Fittings Tube Round Bar. Low alloy steels are generally weldable see What is. In perhaps over simplified terms an E6011 electrode is like an E6010 electrode designed to operate on AC polarity.

This category includes chromium steels containing up to 5 Cr and 1 Mo and nickel steels containing up to 5 Ni. Here are some of the biggest drawbacks of AC welding. A O Ć AK Ć B JOS O Ć A Ć.

Helium is more frequently used than argon as a shielding gas in GTAW. In most cases DC is the preferred welding polarity. The Charpy V notch test is a quality control test used to select steels that.

2014 Influence of welding technology to mechanical properties of welding joints at high strength low alloy steels The 8th International Symposium KOD. Comes at affordable price. Concave bead contour should be avoided.

These steels are not consid-ered alloy steels even though their desired properties are achieved by the. Disadvantages of AC welding.

Herocut Mig Welder Dual Voltage 110 220v Welding Machine Portable Welding Machine Mig Welding Machine Arc Welding Machine

Weld Defects Welding Construction

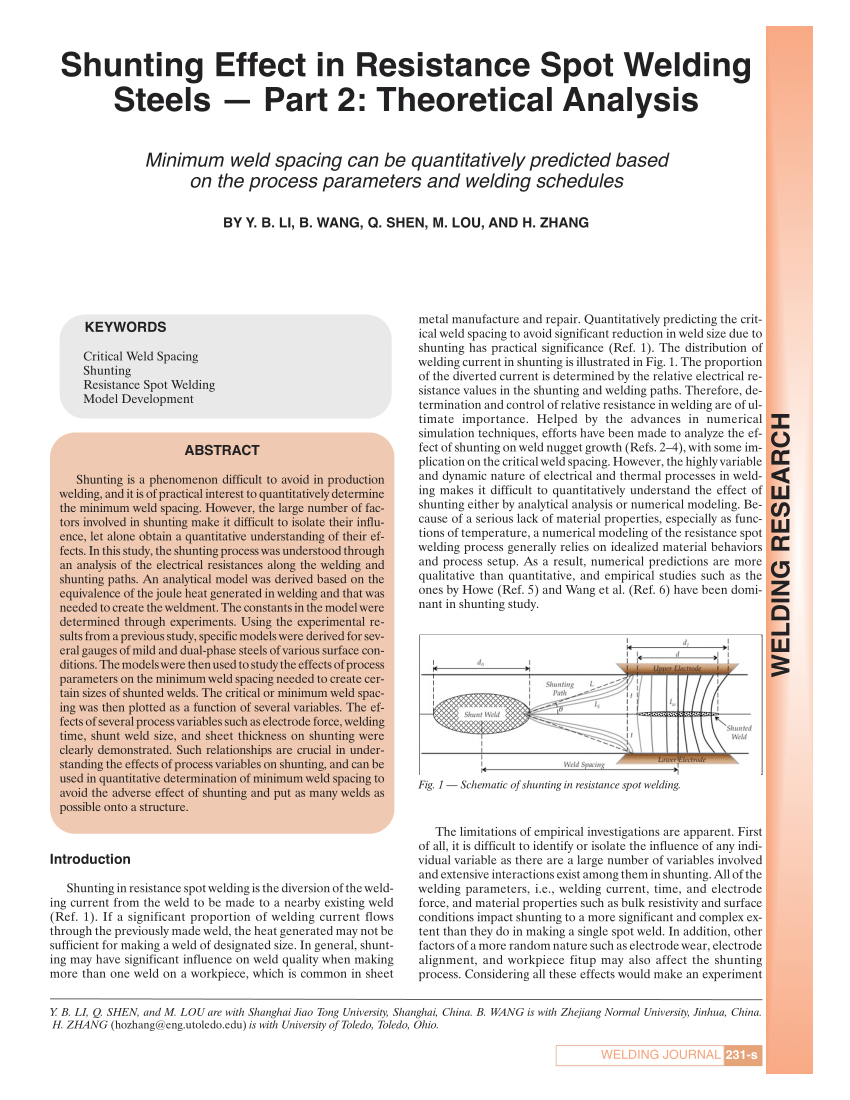

Pdf Shunting Effect In Resistance Spot Welding Steels Part 2 Theoretical Analysis

Welding Structural Steel By Smaw Process Paktechpoint

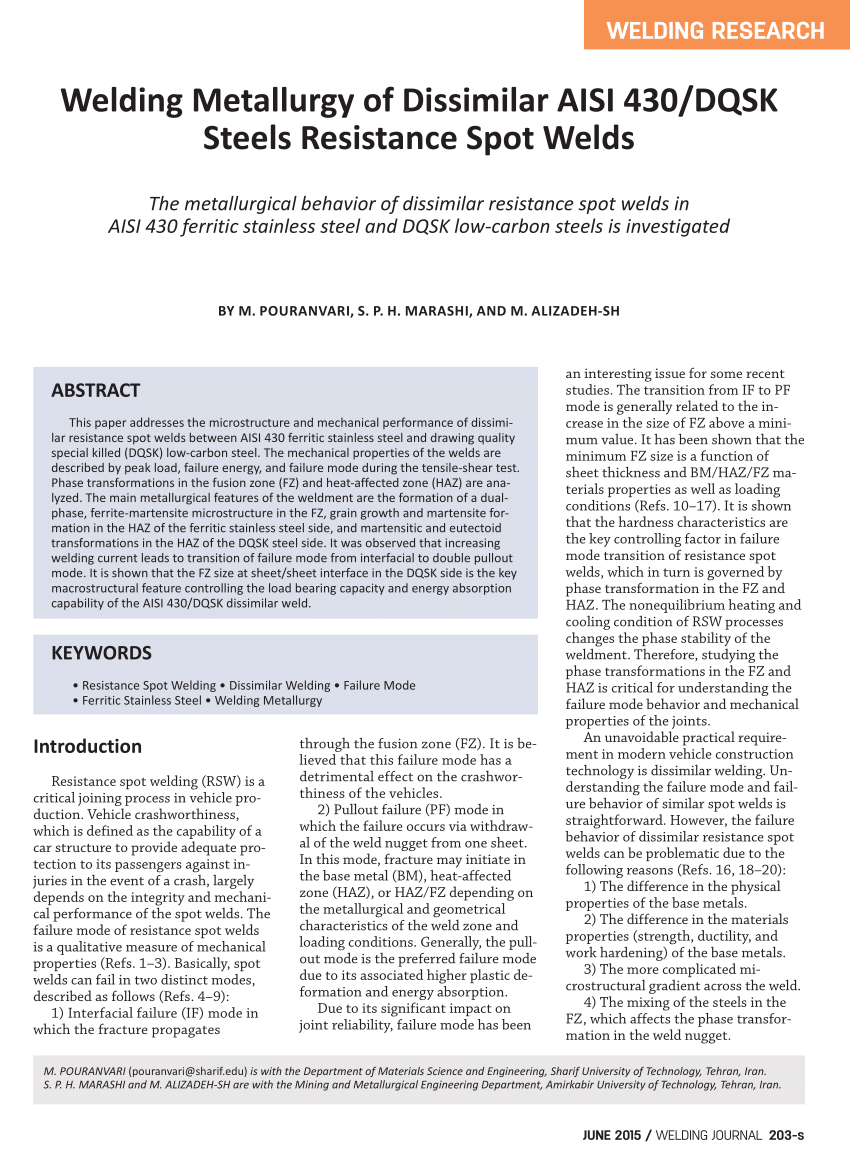

Pdf Welding Metallurgy Of Dissimilar Aisi 430 Dqsk Steels Resistance Spot Welds

Cswip 3 1 Question With Answer And Explanation Part 27 General Technical Knowledge

Sample Wps Smaw Stainless Steel Welding Construction

Welding Technology Welding Construction

Pdf Experimental Investigation And Hardness Analysis Of Chromoly Steel Multipass Welds Using Gmaw

0 comments:

Post a Comment