The two base materials are melted together forming a join. Gas tungsten arc welding GTAW also known as tungsten inert gas TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weldThe weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas argon or heliumA filler metal is normally used though some welds known as autogenous welds or.

Characteristics Of The Mig Welding Process

The welding gun then joins the two metals together.

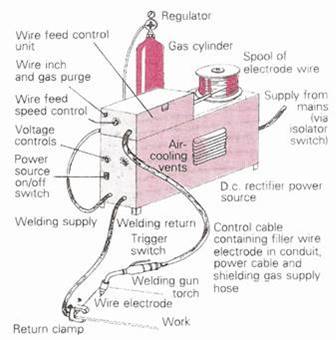

Characteristics of metal inert gas welding. Characteristics of shielding gas. Consumable electrode is fed automatically while torch is controlled either manual or automatically. Metal Inert Gas welding is used for low alloyed mild steel and copper stainless steel aluminum copper alloys and nickel and nickel alloys etc.

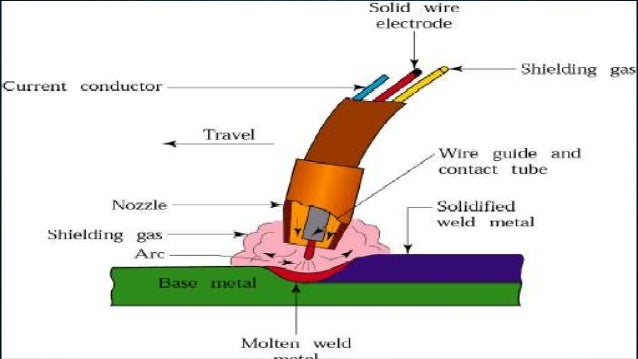

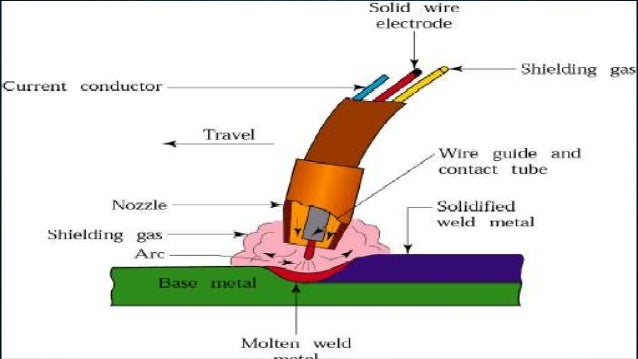

MIG welding includes a solid wire electrode that is heated and fed into the weld pool. For instance MIG is the most popular type of welding within the huge automotive industry which is no wonder providing that it delivers strong and robust welds. The gun feeds a shielding gas alongside the electrode helping protect the weld pool from airborne contaminants.

The welding gun also feeds an inert shielding gas alongside a wire electrode. It melts the base materials together which solidifies and produces bonds using the welding gun. Upward there is no technical limitation but the risk for cold laps at low heat input or oversized pool will increase.

Recently the literature regarding the welding process of Mg alloys has increased rapidly mainly focusing on arc welding 12 laser beam welding 35 electron beam welding 6 diffusion welding 78 and friction stir welding. To know the compare and contrast between MIG welding machine and TIG welding machine. History of the product 2.

MIG welding also known as Gas Metal Arc Welding GMAW is a process that utilizes a continuously fed solid electrode shielding gas from an externally supplied source and electrical power to melt the electrode and deposit this molten material in the weld joint. Metal Inert Gas MIG welding is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. Metal inert gas welding machine 1.

To explain about the function features and characteristic. Hence typical Tig Welding has a simple AC machine that has the shielding gas flow. One of the welding processes that used in Engineering field is the metal inert gas welding.

Such gases remain stable even at extreme arc temperature. MIG Metal Inert Gas welding also known as MAG Metal Active Gas and in the USA as GMAW Gas Metal Arc Welding is a welding process that is now widely used for welding a variety of materials ferrous and non ferrous. Welding is the manufacturing method which is carried out by joining two similar and dissimilar metalsMIG welding is one of the most widely used processes in industry.

GMAW process is the commonly used arc welding process The gas metal arc welding process is most popular known as MIG It is one of the most used joining processes in the world today MIG is referred to Metal Inert Gas GMAW is the joining of two metals by the use of the electric arc and continuously fed filler material. It can weld the plate thicknesses down to 07 mm. Chemically it does not interact with the workpiece material therefore it is carried out in a shielded environment in.

Thanks for the colleagues who give this slides to publish. This helps to protect the process from airborne contaminants. When you weld the metal any type of inert gas secures the metal from preventing the air.

Metal Inert Gas Welding MIG welding is a method of arc welding in an inert noble gas argon and also helium which surrounds the welding wire and the weld. As already said metal inert gas welding is one of the most commonly used methods for joining metals hence its widely applied across different industries. Metal inert gas process is similar to TIG welding except that it uses the automatically fed consumable electrode therefore it offers high deposition rate and so it suits for good quality weld joints required for industrial fabrication Fig.

It is an arc welding processthat uses two materials that are melted together join two points. MIG welding is also known as gas metal arc welding GMAW which uses a continuously fed solid wire electrode. Metal active gas MAG welding utilizes a mixture of inert gas and active gases as shielding gas.

OBJECTIVE AND PURPOSE To tell about the metal inert-gas welding machine. OUTLINE FOR THIS PRESENTATION 1. There are several types of welding processes similar to this but MIG welding has its unique features.

As the name suggests metal inert gas MIG welding utilizes only inert gas like argon or helium. MIG welding metal inert gas welding is a method of arc welding. MIG metal inert gas welding weldingtheory.

The MIG welding parameters are the most important factors affecting the quality. Such active gas mainly includes oxygen and carbon di-oxide. Thus the shielding gas holds the tungsten electrode from oxidation.

MIG Welding or Metal Inert Gas Welding is a common welding process in 2021.

Metal Inert Gas Mig Metal Active Gas Mag Welding

Mig Vs Tig Welding Types Materials And Applications A Guide

Mig Welding Techniques Or Metal Inert Gas Welding Techminy

Difference Between Metal Inert Gas And Metal Active Gas Welding

Metal Inert Gas Welding Welding Consultants For Welding Inverters Metal Inert Gas Welding Welding Machines And Other Weliding Cutting Systems

Mig Welding Metal Inert Gas Welding Kovinc D O O

Metal Inert Gas Welding Process Download Scientific Diagram

0 comments:

Post a Comment