We want to weld studs to a hot-dip galvanized platform frame for grating clips but Ive read that you should not stud weld directly to galvanized steel. The stud itself becomes part of the weld material.

Structure Magazine Welding Cold Formed Steel

The presence of zinc and included zinc vapors in the weld can weaken the weld to the point of failure.

Welding galvanized steel studs. Individual panels of decking. If the end face is still zinc coated the weld metal may be violently expelled from the joint because of volatilization of the zinc from the faying surface. Historically stick welding of light-weight galvanized steel framing has been accomplished with transformer rectifier welding units requiring either single or 3-phase 230-volt 50 ampere DC.

The fabricator is saying the studs will get knocked off during hot-dip galvanizing. This leaves two options. This adds two operations.

Ad Find China Manufacturers Of Welding Wire. 1 Stud weld before galvanizing. Every day millions of welding studs are joined via stud welding processes in many areas of the metal industry.

Ad Find China Manufacturers Of Welding Wire. Number of decking sheets secured together with metal bands also called a pack. To weld a tear or split in galvanized steel start on any edge of the metal.

However the practice of stud welding on galvanized steel remains very common. Arc stud welding joins the base end of the stud to the work-piece by heating the stud and the work with an arc drawn between the two. Extreme care should be exercised when welding through metal.

The power source and the stud welding control system are set to control the amperage and the arc duration which vary due to the type of stud stud. Work slowly around the exterior edge on the metal itself moving forward 23 inches 5176 cm before bringing your welding. Pressed steel formwork for restraint of wet concrete at slab edges.

Galvanizing protects in three ways. Stud welding in the case of welding studs to a structural beam to connect a concrete deck to the beam is typically done using the electric arc stud welding process. Electric arc stud welding was initially developed prior to WWII as a necessity for rapidly attaching wood planking to.

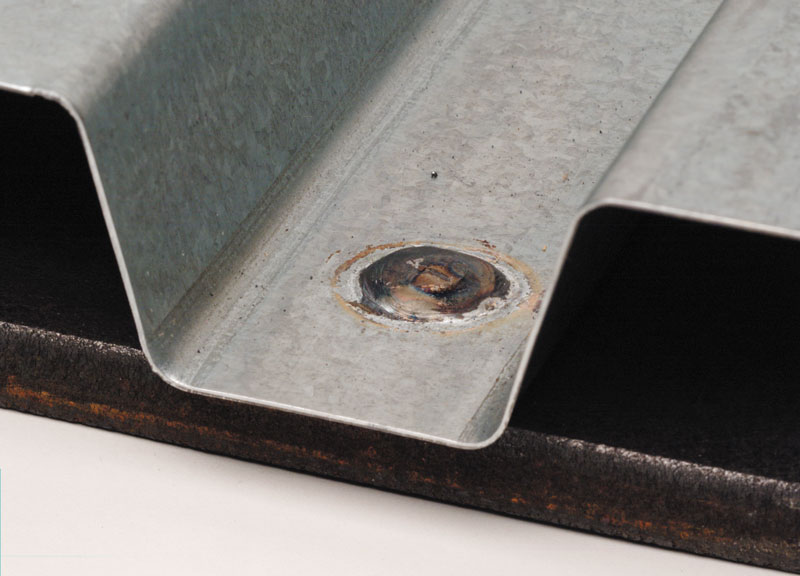

If galvanized studs are to be welded onto galvanized surfaces it is essential to remove the zinc coating from the end of the stud and the surface onto which the stud is to be welded. 742 The stud base shall not be painted galvanized nor cadmium-plated prior to welding. Pre-formed galvanized sheet steel to close gaps between.

The most common method is hot-dip galvanizing in which parts are submerged in a bath of molten zinc. Shear studs is acceptable but welding to galvanized supporting steel beams is not. For hot-dip galvanized steel the same process can be performed but the end results are somewhat different.

It is the purpose of this Advisory Desk Note to clarify why through-deck welding of shear studs is acceptable but welding to galvanized supporting steel beams is not. Welding shear studs directly to non-galvanized steel beams is normally done using electric arc stud welding involving the drawn-arc process. 2 where a 16-to 20-gauge steel sheet coated with Zn has to be fused between the stud and the beam aka.

Stud welding is a general term used to describe joining a metal stud or similar part to a metal work-piece. Work of stud welding safety netting etc. Welding shear studs directly to non-galvanized steel beams is normally done using electric arc stud welding involving the drawn-arc process.

The welding of 12 to 20 gage galvanized steel framing is. 743 The areas to which the studs are to be welded shall be free of scale rust moisture and other injurious material to the extent necessary to obtain satisfactory welds. Best Practice Guide for Welding Hot Dip Galvanized Steel Edition 1 February 2019 Introduction 1 Best practice welding of uncoated steel 1 Appearance of the welded area 1 Chemistry of the welding rod 1 Managing weld splatter 2 Removing welding slag 2 Welding overlapped surfaces 3 Welding to minimise distortion in the galvanizing process 3.

Galvanization or galvanisation or galvanizing as it is most commonly called in that industry is the process of applying a protective zinc coating to steel or iron to prevent weld studs rusting. Welding through a galvanized corrugated steel sheet deck has been a special application of stud welding Ref. This corrugated deck is.

Drawn Arc Stud Welding stud welding is a particularly economical welding process for joining round-shaped metallic parts studs welding studs welding elements with metallic workpieces such as sheet metal profiles and pipes. This seems like utter nonsense to me. The best way to weld galvanized steel regardless of welding process is to remove the zinc coating from the joint.

These may be cleaned by wire brushing scaling prick-punching or grinding. Removing the coating and re-spraying or painting the weld seam after welding to regain corrosion resistance. These welding units can typically furnish a current out-put range of 30 to 250 amperes at 30 arc volts with positive or negative polarity.

Welding can be done with many processes such as arc resistance friction and percussion. The power source and the stud welding control system are set to control the.

Galvanized Steel And Stud Welding American Galvanizers Association

Stud Welding Thru Deck Pfs Is Here To Help Pfsno

China 304 Stainless Steel Stud Welding Bolt Welding Studs M3 M8 China Stud Bolt Welding Stud Welding Bolt

Structure Magazine Welding Cold Formed Steel

Galvanized Rebar Steel Anchor For Drawn Arc Stud Welding Buy Galvanized Rebar Steel Headed Deformed Bar High Quality Rebar Product On Alibaba Com

Stud Welding Materials Which Materials Work Taylor Studwelding

0 comments:

Post a Comment