Dissimilar lightweight material welding is used to connect different metals together for automotive industries Used where an object is subjected to multiple environments in one application such as in chemical and petrochemical industries power generation and oil. Especially in some materials combinations 100 joint efficiency was attained.

Welding Together Of Dissimilar Metals Works Perfect With Our Wobble Laser Welding Machine Fiber Laser Welding Of Dissimilar Metals Welding Dissimilar Metals Laserwobblewelding Com

When a given combination cannot be welded directly interme diate metals may be used.

Welding of dissimilar metal combinations. Various dissimilar combinations of metal have been welded including steel to copper base alloys steel to aluminum stainless to nickel base alloys. A36 is a low-carbon steel that offers good strength and formability. Ultrasonic welding can be used only for very thin materials or small parts.

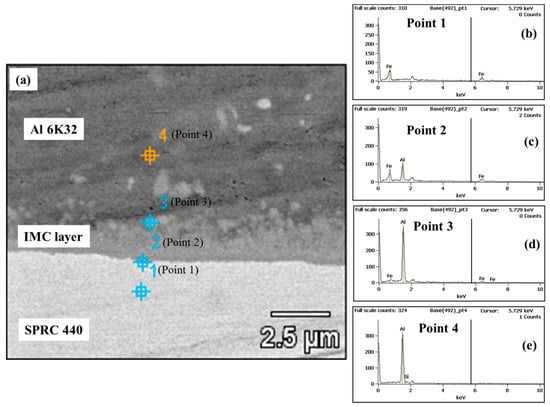

The type of welding typically used for dissimilar metals is fusion welding which welders also use for joining similar metals. For this discussion a dissimilar-metal weld will be that between metals of two different alloy systems. The composition of the intermetallic layer.

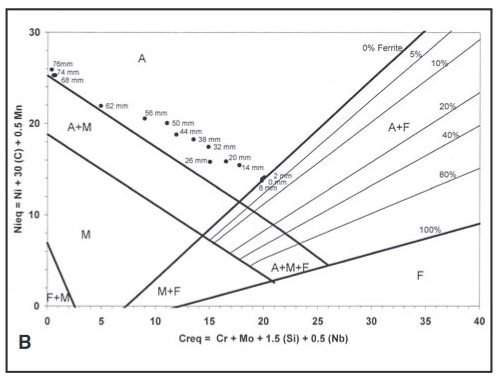

When welding such dissimilar metal welds the choice of filler metal plays a big role and usually has a composition differing from both of the parent metals. Filler wire type 309 25Cr12Ni or 310 25Cr20Ni Dissimilar. Depending upon mutual solubility between dissimilar materials we may define group of compatible dissimilar materials suitable for welding and in some cases fulfilling the pre-requisite conditions for specific combination.

The processes under this category suitable for the welding of dissimilar metal combinations are electron beam welding laser beam welding and pulsed arc welding as shown in Fig. Base metal Stainless steel 304308 type Filler wire type 30925Cr12Ni. There are some material combinations that are common when welding dissimilar metals.

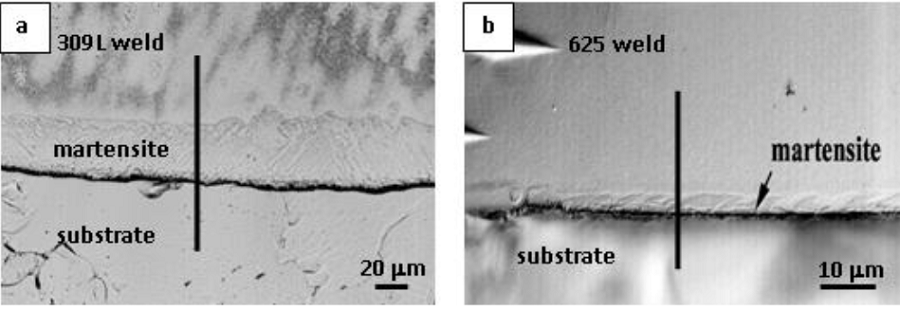

Durable dissimilar metal weld between low alloyed or carbon steel and stainless steel. Welds are dissimilar-metal welds DMWs because the metals being joined have a wrought structure and the welds have a cast structure. Joining of dissimilar metal combinations is however a challenging task owing to the large differences in physical and chemical properties which may be present.

Frequently the match-ing-composition filler metal is deliberately altered from that of the base alloys. Weld quality can be performed with a destructive test hardness bending and tension test Microstructure SEM and EDS and non-destructive test Magnetic particle radiography ultrasonic. Laser welding a high power density but low energy-input process provides solutions to a number of problems commonly encountered with conventional joining techniques.

Has several advantages for welding dissimilar metals. Adshelpatcfaharvardedu The ADS is operated by the Smithsonian Astrophysical Observatory under NASA Cooperative Agreement NNX16AC86A. Joining of hinges or other MSLAS members to SS wagons 3Cr12 type.

In some instances a welder may need to determine another method for joining dissimilar metals. A schematic picture of a dissimilar metal weld is presented figure 1. For all these types of joining the welder will need to consider.

Joining of dissimilar metal combinations is however a challenging task owing to the large differences in physical and chemical properties which may be present. Welding of Dissimilar Materials Combinations for Automotive Applications. Friction welding is also used for joining dissimilar metals and for making composite transition inserts.

Consider the best practices to achieving the best results. The ability to precisely locate the weld and the favorable shape of the fusion zone permit good control of the relative amounts of the two metals in the weld metal. It can be used for all metal combinations on dissimilar welding likely low carbon steel and stainless steel or stainless steel and stainless steel etc.

M4 class of IRS M. The very narrow fusion zone of the electron. Ultrasonic welding is also used for welding dissimilar metals since very little heat is developed at the weld joint.

Laser welding a high power density but low energy-input process provides solutions to a number of problems commonly encountered with conventional joining techniques. Welding A36 to A514 The combination of these two steels is often found in structural construction or heavy equipment welding. Stainless Steel trough floor with Mild SteelCorten Steel.

This study was carried out to obtain sound welds and to select a most suitable binary metal joint among three different dissimilar binary metal combinations such as. Based on these welding concepts healthy welding between so many kinds of dissimilar metal combinations such as steelAl alloys steelCu alloys and stainless steelAl alloys were realized up to today. Resistance and Solid State Welding.

Metals Special Issue Dissimilar Metal Welding

Metals Special Issue Dissimilar Metal Welding

Pdf A Review On Welding Of Dissimilar Metals In Car Body Manufacturing

Dissimilar Metal Welding An Overview Sciencedirect Topics

Metals Special Issue Dissimilar Metal Welding

Process Variants Of The Ultrasonic Metal Welding Method Download Scientific Diagram

Metals Special Issue Dissimilar Material Welding And Joining

Welding And Joining Dissimilar Metals Part 1 Engineering360

Welding And Joining Dissimilar Metals Part 1 Engineering360

0 comments:

Post a Comment