The root pass is the first pass on an open joint usually when welding pipe and mild steel. A seam weld is.

Welding Sequence For Buttering Root Hot Fill And Cap Passes Of The Download Scientific Diagram

It can be made using single or multi-pass welds.

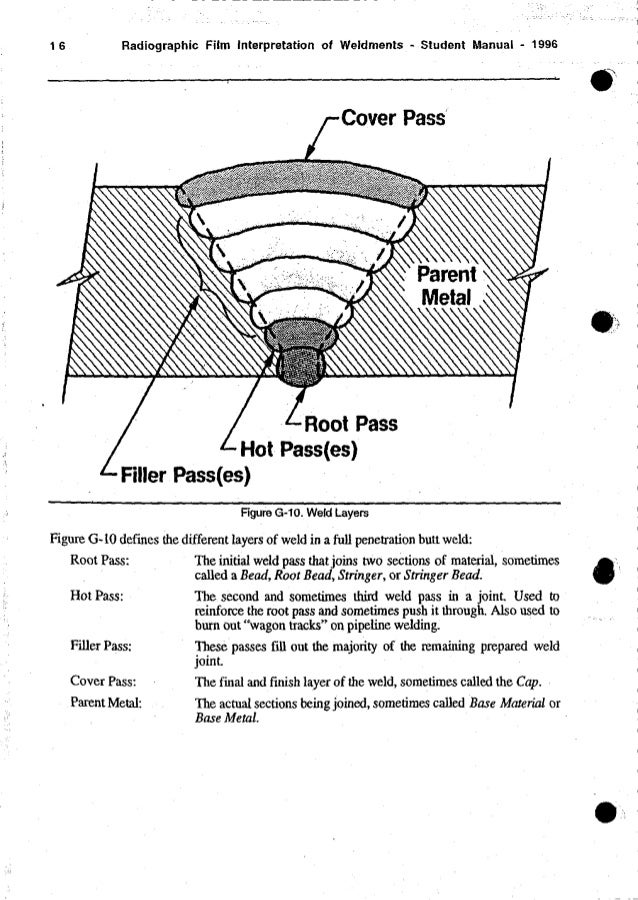

Welding passes meaning. Pass temperature if required. In Multi-pass Welds the nomenclature of the weld the zones affected by the welding heat when a butt weld is made by more than one pass or layer and the nomenclature applying to the grooves used in butt welding are shown in figure 6-14. Figure 6-15 is based on weld type and position.

Different people had a different opinion and they are as below mentioned. The root penetrates through the back of the plate the cap is on the surface which you are welding which is the face. Well that doesnt tell us much so lets dig further.

Root Pass - A weld pass made to produce a root bead page 32. The surfacing welds are used when you need to apply welds over the entire surface of a welded piece or a part of it. Here are some things that will determine number of passes.

The result of a pass is a weld bead. Welding is usually used on metals and thermoplastics but can also be used on wood. - Welding processes which use heat from the resistance of current flow and arc rays to produce coalescence of metals.

Face - On plate or pipe welding there is a ROOT PASS HOT PASS FILLER PASS and CAP. If the WPS does not specify youre free to use as many or as few passes as your skills allow. See DUTY CYCLE Some fans run constantly while others run on demand which means it comes on.

A hot pass is a term used in stove-pipe welding when the bead is complete it is given a quick clean up with a grinder then the hot pass follows it burns out the slag that is trapped at the junction between the bead and the pipe wall the slag is often called wagon tracks. Weld pass noun. Internal Resources Subarc for structurals.

When the minimum specified preheat temperature is reached when the first crayon mark melts the first welding pass can commence. 1 The surfacing weld symbol shall be used to indicate surfaces built up by welding fig. High travel speeds equal low weld volume.

Seam welding is a resistance welding process in which suitably contoured copper electrodes apply pressure to create a region of high resistance between metal sheets. Root - A nonstandard term when used for joint root or weld root page. The welder first heats the joint to be welded and checks the base metal temperature at the code-designated location by marking the base metal with the first temperature indicating crayon.

First and foremost you have to review your welding procedure specification WPS to see what the minimum or maximum pass number requirements might be. A single progression of welding or surfacing along a joint or substrate. Weld Pool The localized volume of molten metal in a weld prior to its solidification as weld metal.

Weld Pass A single progression of welding along a joint. The current passed through this region generates heat due to high electrical resistance. I know its an old out of date version but its all I had.

The result of a pass is a weld bead or layer. There are certainly many answers for what exactly does HOT PASS means in welding terminology and from where it actually evolved. It is usually used as a first pass that will provide the base for subsequent filler passes.

Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool. Weld Puddle A nonstandard term for weld pool. 2 The surfacing weld symbol does not indicate the welding of a joint and thus has no arrow or other side significance.

The hot pass refers to the second run of a multipass weld where sufficient arc current is required to achieve good sidewall fusion while at the same time avoiding repenetration through the root run. Since it is bridging a gap it may be done with a quick freezing rod with a cellulosic flux like 6010 or 6011. Commonly used to reinforce a piece or to repair the worn-down elements.

A hot pass is a term used in stove-pipe welding when the bead is complete it is given a quick clean up with a grinder then the hot pass follows it burns out the slag that is trapped at the junction between the bead and the pipe wall the slag is often called wagon tracks. It is to fill the weld bevel. Welding machines have a fan to cool the machine down and keep it from overheating.

Can use either direct DC or alternating AC current consumable or non-consumable electrodes with or without the application of pressure. The completed welded joint may be. It is to melt and float out the wagon tracks left after the root pass.

To satisfy these criteria synchronised pulsing combined with end dwells on cross seam oscillation can be used to control the fusion characteristics. The primary heat affected zone is the area fused or affected by heat in the first pass or application of. Weld Reinforcement Weld metal in excess of the quantity required to fill a joint.

3-58 whether built up by single-or multiple-pass surfacing welds.

Tips Weld Steel Pipe In 6g Using Smaw

Welding Sequence For Buttering Root Hot Fill And Cap Passes Of The Download Scientific Diagram

Hot Pass In Welding Terms Amarine

Welding Joints Positions And Symbols Ppt Video Online Download

Welding Different Passes A Initial Pass And B Cap Passes Download Scientific Diagram

Multi Pass Welds Maine Welding Company

Multipass Weld An Overview Sciencedirect Topics

0 comments:

Post a Comment