Internal welding defects exist in the material at some depth and are hidden from naked eyes. Welding Defects Eurotech Now inteducing Welding Defects.

Mechanical Engineering Different Types Of Welding Defects

1 Weld Crack 2 Undercut 3 Spatter 4 Porosity 5 Overlap 6 Crater b.

6 welding defects. Surface Cracks Undercut Porosity Overlaps Crater Underfill Spatters Excessive penetration Arc Strike etc are examples of external welding defects. It can also occur when the speed of the weld is too fast or if you use. Weldings defects are classified into the following types.

A list of weld defects and their causes is given in Table 111. Incomplete penetration Slag inclusion. Incompletely filled groove or Incomplete penetration.

Welding Defect is any type of flaw in the object which requires welding. External welding defects are found on the surface itself and can sometimes be recognized by naked eyes. Principal Customers Internal customers are.

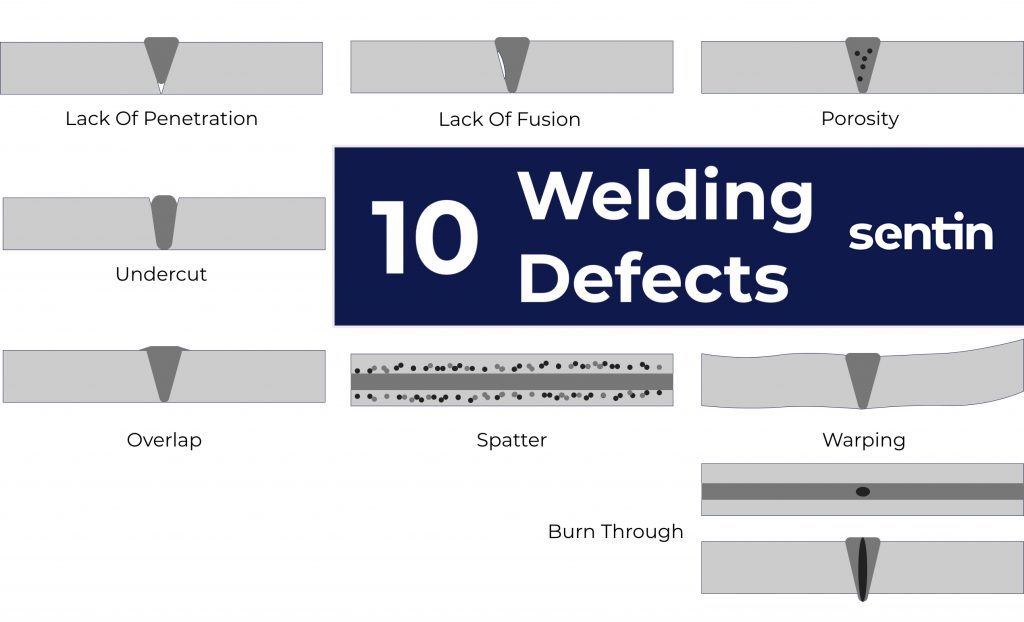

Increase in SAW welding machine process yield. Lack of fusion 2. Defects affect the quality of weld Porous welds Poor penetration Warping Undercut Underfill Distortion Cracked welds Poor appearance Poor fusion Brittle welds Spatter Magnetic blow Weld stress.

The defects in the weld can be defined as irregularities in the weld metal produced due to incorrect welding parameters or wrong welding procedures or wrong combination of filler metal and parent metal. External Welding Defects. Undercut is one of the welding defects that occur when the voltage of the arc is too high.

Lack of penetration or excess penetration 3. Other defects not listed are mainly those of geometry and include misshapen and incorrectly sized welds variable cap width and height weld face roughness incomplete weld fill and asymmetry of fillet welds. 1 Slag Inclusion 2 Incomplete Fusion 3 Necklace cracking 4 Incompletely filled groove or incomplete penetration 20 External Welding Defects.

Tank weld consumable Perform Welding by SAW welding Welded shells welded Dish ends Inspection Logistics Department External customers Suppliers Input Process Output Customer Process Deliverables 1. Reduction of non-production idle hours. Incorrect profile Crater Cracks Spatter and surface porosity Incomplete filled groove Distortion Blowholes and internal porosity Cracks Inclusions Lack of fusion Incomplete fusion.

Seven type of Welding Defect Seven type of Common weld defects include. Weld defect may be in the form of variations from the intended weld bead shape size and desired quality. Using the right electrodes and proper welding technique will also help prevent this problem.

Welding Defects Classification Causes And Remedies Welding Ndt

Different Types Of Welding Defects And Remedies Student Lesson

Welding Defects Cause And Remedies Youtube

What Is Welding Defects Types Causes And Remedies The Welding Master

Defects Welding Projects Welding Types Of Welding

The 10 Common Weld Defects You Should Know Sentin

Https Xn 80apgfhelckg6l Xn P1ai Education Welding Defects Causes And Remedies Php

Welding Defects Types Causes And Remedies With Pdf Quiz

Welding Defects Appears In Radiography Test

0 comments:

Post a Comment