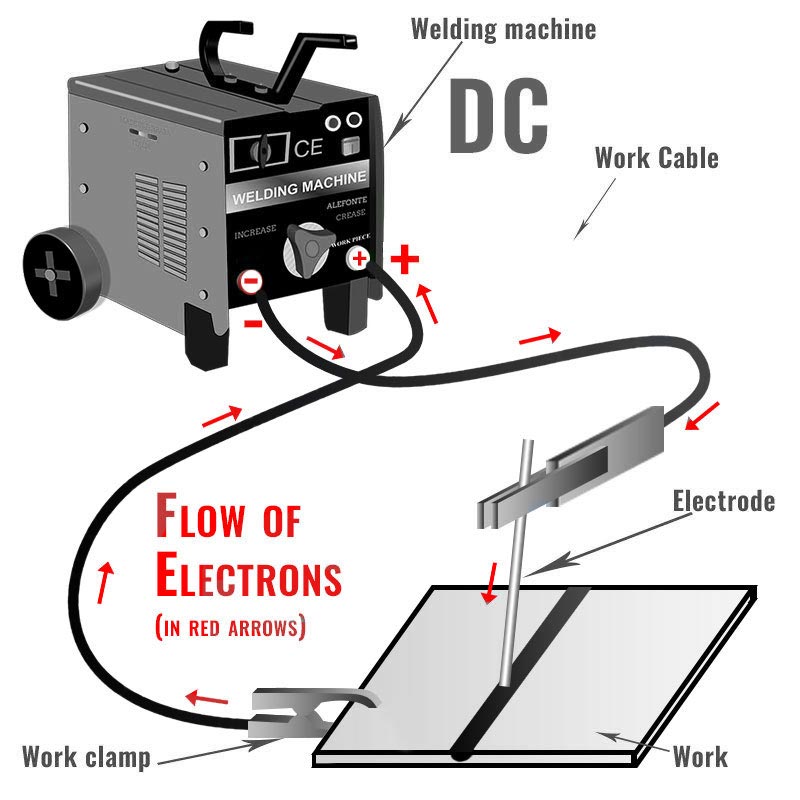

Welders are commonly grounded using a ground clamp typically made of copper or brass. The work lead should not be referred to as the ground lead.

Earth Clamps Why You Will Never Get A Good Weld With A Bad Clamp

A grounding weld can be attached at two placeseither the metal welding workbench itself or the work that is being welded on.

How to properly ground for welding. In general as the included angle increases the weld penetration increases and the width of the weld. Various electrode tip geometries affect the weld bead shape and size. This is done to complete the circuit and allows the welder to create an arc.

You must connect the workpiece or work table to a suitable ground such as a metal building frame. Which the welder welds and is normally grounded independently of the welding leads to a good electrical ground unless a qualified person assures it is safe to work on an ungrounded workpiece. This means that each stud makes a neat hole through the sheet metal component.

They inspectors used to do that here unsure if they still do it though say if a machine were to have a generator problem and short its arc to frame ground. The best way is to attach the ground clamp directly to the workpiece. Improperly grounded welding machine.

What you want is to have that welding current limited to JUST the area in which you weld. This is the basic method for grounding a welding table. The ground connection should be independent of or separate from the welding circuit connection.

Youve got more than a few problems including arcing and sparking to that common earth ground where everybody is attached. For the latter the end is typically ground to a specific included angle often with a truncated end. To expand on this some welding processes TIG for example can best be performed if the ground clamp is in very close proximity to the electrode.

When you have mastered controlling the arc you will begin to practice laying or building up the weld bead. Whenever you weld you need to make sure the machine is properly grounded. Grounding the workpiece has similar benefits to grounding the welding machine enclosure.

Grounding involves running a ground wire from the machine to an appropriate grounded source such as a grounding rod driven several feet into the ground. This prevents a straying arc common with the TIG process. Set the flow rate to around 20-25 cubic feet an hour and make sure that the gas is switched on.

Using tin snips or a file round off the resulting sharp corners and file it all up nice and smooth. Without a good ground it could compromise weld quality consumables or even stop you from welding. Electrodes are usually used.

The polarity will depend on the electrode you are using. How to Get a Good Welding Ground - Kevin Caron - YouTube. The purpose of grounding a welder is to provide a location for the electricity to discharge to the ground.

This technique provides a proper clean metal to metal contact between the stud and the sheet metal part in thin sheet applications 07mm to 21mm. When using welding machines or portable generators be sure that they are properly grounded before you start the machine. It is vital that you ground your welder before you begin working.

Apply your ground clamp close to the weld point so the current flow only occurs through a short distance the arc a little of the parent metal and back to the welding leads both for. Then there is the soil conditions ect ect. Gently flatten out the handle with a small hammer.

Practice traveling across the path of your weld with the electrode until you can keep a consistent arc moving at a consistent speed and in line with the path you want to weld. One of the clearest advantages of Profil grounding studs is that they are self-piercing. The next step involves hooking up the ground clamp to the metal you will be working on.

Work LeadThe electric conductor be- tween the source of arc welding current and the work. This is easy MIG welding techniques require you to use a reverse polarity DC electrode positivity on some machines. Starting the arc welder stick is actually easy.

Youll find these settings typically on the interior of the machine. Then choose your gas flow. If a machine is not grounded correctly the electrical current will use the welder as a human ground.

Attaching the welding clamp flush to the underside of a workbench will keep it from getting in the way during a weld. The final step includes putting the electrode in the stick holder and starting the welders arc. Place the offending earth clamp into your vice and saw through the handle that holds the cable leaving around 15 40mm of the handle attached to the cable.

How To Ground Your Welder A Helpful Guide Welders Lab

How To Ground Your Welder A Helpful Guide Welders Lab

Should Welding Tables Be Grounded Welding Troop

Grounding And Arc Welding Safety

Grounding And Arc Welding Safety

How To Get A Good Safe Welding Ground How It Works And How To Work It Kevin Caron Youtube

How To Ground Your Welder A Helpful Guide Welders Lab

How To Hook Up Stick Welding Leads Welding Tribe

0 comments:

Post a Comment