Following is a brief explanation of each. Its best to do this inside in a darker area so that youll notice when it starts to glow.

Window Grill Stock Photos Images Pictures Window Grill Wrought Iron Design Window Grill Design

Take your time heating it.

How to weld ornamental cast iron. Remove paint grease oil and other foreign material from the weld zone. Iron starts to glow dull red at about 900 degrees F. However we are discussing the most used and popular techniques for welding cast iron.

Typical preheat temperatures are 500-1200 degrees F. The following is a step by step guideline on how you can fix cracked cast iron. It is best to apply heat carefully and slowly to the weld area for a short time to remove entrapped gas from the weld zone of the base metal.

One way to handle this is by controlling the cool-down of the cast iron. This technique is commonly used to correct cracks on cast iron items. How to weld cast iron with a MIG welder.

Although wrought iron is easy to weld it also tends to lose its desired traits when there is deep penetration as the fibrous slag inclusions melt and reform reducing the materials toughness and ductility or otherwise migrate to the weld pool and weaken the joint. Welding Cast Iron Cast Steel. Brazing isnt really welding as it doesnt fuse the metal as a weld does.

Then fix any cracks or rips in the. Preheating the cast iron part before welding will slow the cooling rate of the weld and the region surround the weld. To maintain a nice weld use the MIG welder to maintain the lowest feed rate and the lowest current.

The V should extend to approximately 18 in. While this is the short answer there is a bit more to unpack to tackle this bit more challenging stick welding project. Methods for welding wrought iron include forge welding oxyacetylene welding and shielded metal arc welding SMAW.

By choosing the right filler material and welding method you can weld cast iron along with other welding processes such as MIG TIG welding. Both can be welded very easily with MIG. However once you select a method stick with it.

Procedures Welding Gray Cast Iron. At this point youre catering mostly to the cast iron since the steel is generally highly weldable. Weld in very small points at a time not larger than 5-10 mm.

Dont heat over 1400 degrees F since that will put the material into the critical temperature range. Gas welding Arcstick welding MIG welding and TIG welding are the four widely used methods to weld a cast iron. In general it is preferred to weld cast iron with preheat--and lots of it.

So if you get your rosebud torch on it and let it just start to glow then you know youre at a good temperature for welding. But another way to successfully weld cast iron is to keep it cool--not cold but cool. Below both methods will be described.

Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it. For ornamental work there is NO WAY that I would ever go back to stick. To weld cast iron start by preheating the section youll be working to a temperature between 500 to 1200 degrees F so that its stable enough to work with.

The edges of the joint should be chipped out or ground to form a 60 degree angle or bevel. Oxy-acetylene welding is another option frequently used to weld cast iron. The most common method of cast iron welding is stick or arc welding.

A small hole should be drilled at each end of the crack to prevent it from spreading. It is always preferred to heat the entire casting if possible. Generally cast iron can be stick welded by preheating the material to 350F before welding and adding a slow cooldown phase in an insulating medium like sand to prevent heat cracking.

The casting must be completely clean in the area of the weld. Thoroughly clean the surface to be welded grind file dress and dry. Some people do things like bury the weld it hot sand or cover it with a ceramic fiber blanket with a high temp rating like the one here on Amazon.

Unlike the traditional welding technique used to repair metal items brazing uses minimal heat to fix your cast iron pieces. 32 mm from the bottom of the crack. Since I transitioned into decorative metal work from ranchfarm welding I started with my stick welder.

Its mild steel for the structural components like tubing and some cast iron pieces for looks.

A Blog Featuring Custom Ornamental Metalwork By Potter Art Metal Studios Including Wrought Iron Wrought Iron Corbels Wrought Iron Furniture Wrought Iron Decor

Components City Ornamental Iron Romanesque Repeating Patterns Iron

50 Easy Diy Welding Projects Ideas For Art And Decor Welding Projects Wrought Iron Shelf Brackets Welded Metal Projects

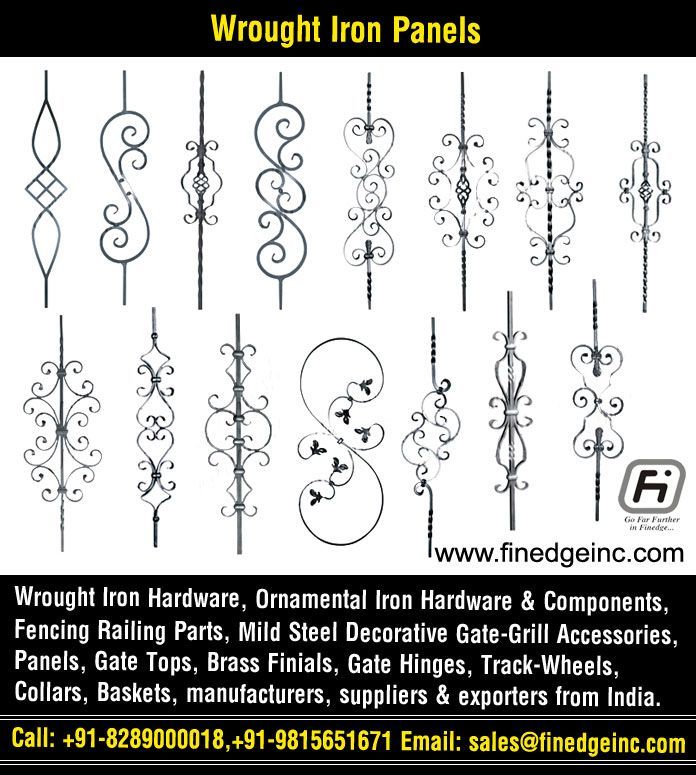

Decorative Wrought Iron And Ornamental Iron Components Fencing Hardware Railing Parts Gate Grill Parts W Iron Decor Wrought Iron Hardware Wrought Iron Decor

Raleigh Wrought Iron And Fence Co Welding And Fabrication Light Structural Wrought Iron Window Baskets Metal Furn Iron Doors Metal Fireplace Iron Furniture

2 99 Gbp Cast Iron Decorative Fancy Double Horse Shoe Hook Coat Hanging Hook Hanger Pegs Ebay H Horseshoe Projects Horseshoe Crafts Projects Horseshoe Art

Impressive Wrought Iron Gates With Grape Vine Details At 1stdibs Wrought Iron Gates Iron Gate Design Iron Gates

Wrought Iron Panels For Stairs Wrought Iron Products Wrought Iron Product Design Gallery Iron Gate Design Wrought Iron Wrought Iron Gate Designs

Wrought Iron Railheads Tops Manufacturers And Ornamental Iron Railheads Tops Exporters From Indi Wrought Iron Gate Designs Wrought Iron Fences Iron Gate Design

0 comments:

Post a Comment