It is suitable for manufacturing stamped and rolled thin plate components that can be overlapped the joint does not require air tightness and the thickness is less than 3mm. The arch process of robotic welding is among the most common types.

Robotic Welding Is It Worth It Pwp Industrial

A wire feeder sends the filler wire to the robot as it needs it for a welding job.

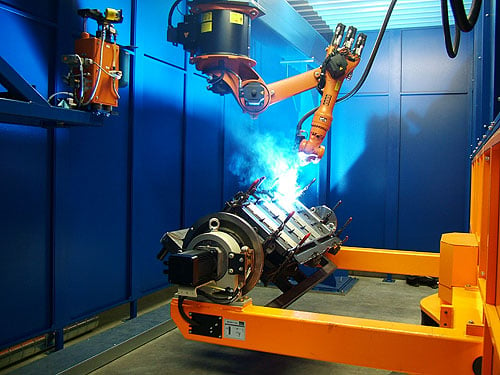

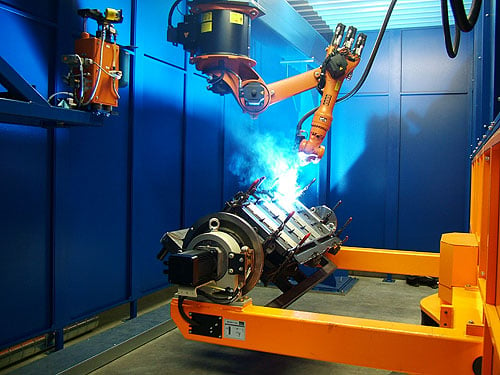

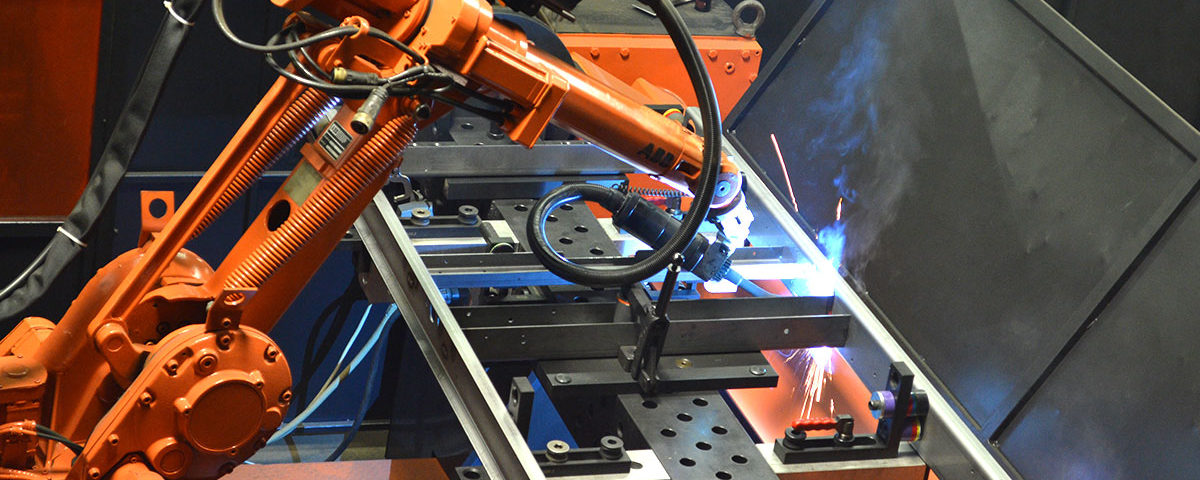

How to welding robots work. A robot typically works between two or more work stations. Tectilinear types of welding robots are able to move their arms in three dimensions while articulating can move in more planes. Heat conduction laser welding and deep laser welding.

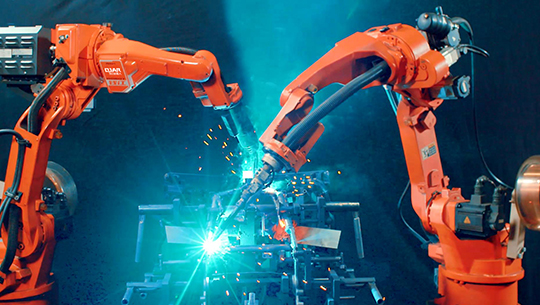

Spot welding involves holding two electrodes to either side of the two pieces of metal and passing an electric current between them. Robot programs can be developed quickly to get the robot into production with minimal downtime. How Does a Welding Robot Work.

As more and more welding becomes automated it is necessary for these welders to be trained to operate welding robots instead of just learning the skills of welding itself. The prototypes are planned to be initially used in Fincantieri shipyards. Because the temperatures reach thousands of degrees using robots for this process keeps people safer.

These components include those actively taking part in the welding as well as accessories and safety features to ensure the smooth operation of the cell. The power source stand is used to mount the welding power supply. Spot welding is to weld individual points on the contact surface.

Welding robots to take over hard work in shipyards. Italy Fincantieri and Comau signed a letter of intent to develop prototypes of robotized steel welding solutions and the resulting construction of a series of machines. Linear tracks allow the welding robot to extend its reach performing the work of multiple robots.

Parts of metal are joined together by the molten metal solidifying after cooling to make the connection stable. How does the automatic welding robot work. Common programming language with all FANUC robots makes it easy for all plant personnel to work with any robot.

The weld wire conduit installed between the wire feeder and the welding wire holder provides the conduit for the wire to travel to the wire feeder. During this process extreme heat of about 6500 F is generated by an electric arc forcing the metal to melt. The welding equipment delivering the energy from the welding power source to the workpiece and the robot providing relative positioning of the heat source and the workpiece.

There are two types of laser welding. Spot welding is a high-speed and economical connection method. A high-heat torch at the end of the arm melts metal to enable the welding process.

Welding robots use a variety of tools that are not a part of manual equipment. Becoming a highly skilled welder takes years of experience training and practice whereas a robotic welding cell operator only has to load the part press the appropriate buttons to activate the machine and then unload the part. This video shows you the basics on how to program a welding robot to perform both linear and circular welds using the Gas Metal Arc Welding MIGGMAW proces.

This heats up the metals melts them and joins them together. Examples include the setup and use of established weld procedures for various joint conditions common in your operations. Easy programming for your welding robots ArcTool software provides an easy to understand user interface using common welding terms.

The training of a robot operator can literally take less than an hour. The electrode is held in the wrist of the robot. This means that during the robot welding cycle the operator is unloading a welded assembly and then loads new components to a welding fixture.

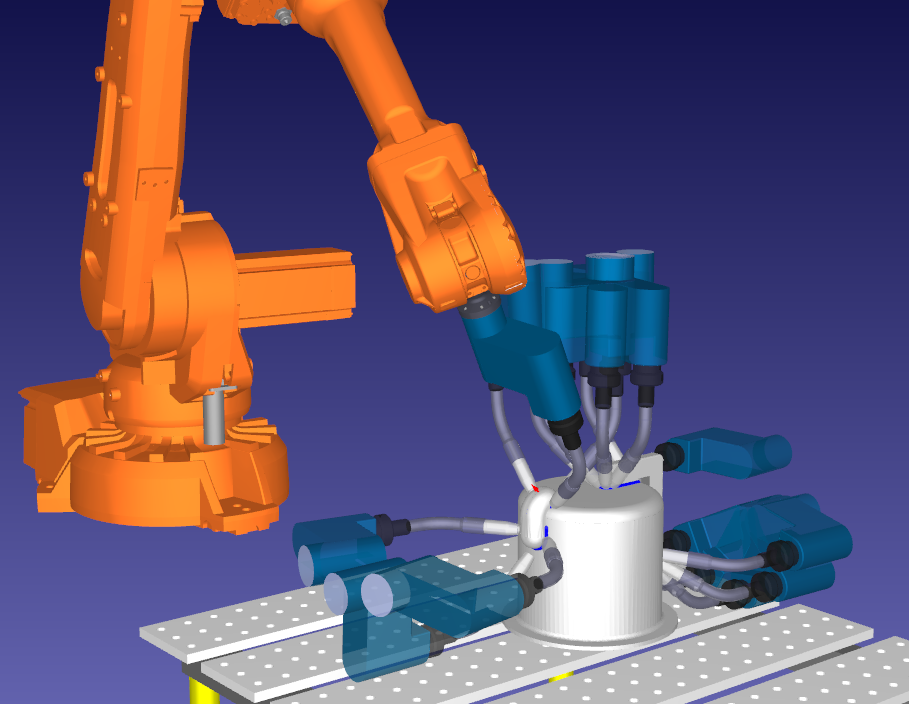

Basics of robotic arc welding A basic robotic arc welding system is formed by two subsystems. Robotic laser welding works slightly differently than traditional welding methods. Other welding-related tips can help simplify the process.

Because there is less handling compared to a manual weld cycle the robot achieves much higher levels. Benefits of robotic welding Productivity. Articulating robots are usually used for performing spot welding.

Welders are an integral part of the manufacturing workforce today. Spot Welding The robot joins two pieces of metal together by welding at several points. Robotic spot welding is majorly used in the assembly lines of the automotive industry.

A wire feeder will send the filler wire to the robot while a. These robots move to the required place and come back within seconds after performing the spot weld. Some of the practices outlined in welding codes can help to control the application of robots for the fabrication and manufacturing world.

Heat conduction laser welding is used primarily for thin parts. There are many different paths someone can take to obtain the welding robot training needed to become successful in the industry. A robot welding unit also called a robot welding cell consists of several components working together to weld pieces.

Certified human operators still need to remain close to the robots.

What Is Included In Robotic Welding Systems

5 Factors To Consider Before Moving To A Robotic Welding Process

Robotic Welding Applied Industry And Case Study Evs Robot

Robotic Welding Leads To Increased Uptime And 85 Efficiency

State Of The Art Of Robotic Welding Metal Working World Magazine

The Simple Way To Flawless Robot Welding Robodk Blog

Robotic Welding Vs Manual Welding Mac Metal

The Simple Way To Flawless Robot Welding Robodk Blog

Should You Use Mig Or Tig Robotic Welding In Your Application

0 comments:

Post a Comment