14 or 15 can be made by forming projections in. In the case of spot welding the recommended amount of water flow at each electrode is 15 gallons per minute.

Pdf Temperature Measurement During Resistance Spot Welding Using A Digital Camera

Although this decreases the current density the electrical resistance is increased by the raised temperature which maintains high heat generation to allow welding.

Projection welding temperature. When s t u d ying the effect of projection design on weld formation and weld quality many earlier researchers had to rely on experi-mental techniques such as consecutive cross sectioning and high-speed motion p h o t o g ra p h y. In the finite element model the temperature-dependent material properties were taken into account. The projections concentrate on the current flow once the mating parts are got together.

As the welding proceeds the spot s becomes larger. Two flat pieces of low-carbon steel however require a projection of some sort. Material properties with temperature and phase changes the projection welding process is difficult to analyze.

There are two round wires put together at 90 degrees form a point contact. Projection welding is a type of resistance welding that focuses current and force to a single point or line at the beginning of a weld. One of the main differences between conventional sheet-to-sheet resistance welding and projection welding is that projection welding is a dynamic process involving considerable movement of the upper electrode.

Projection welding is actually a modification of spot welding the pioneer resistance welding process. While it can be also used to join thinner metal pieces together that tends to be a job left for spot welding. Properly located water tubes at inside weld face.

Projection welding is an ideal method of fastening attachments eg. The projections should be properly formed without any partial shearing. Generally speaking when joining parts of different material thickness place the projections in the thicker of the two componentsgreater thickness means more mass and therefore a longer weld time to reach the required welding temperature when compared to the thinner component.

The projections should collapse during welding without splashing between the sheets being welded. Heat is concentrated on the projection s to soften the material and the welding starts. The process uses two shaped copper alloy electrodes to concentrate welding current into a small spot and to simultaneously clamp the sheets together.

The projections might be round dimples circular elongated ridges or else weld nuts prolonged corners. Case Electrodes Form Thickness Substrate Tempering Nugget Spatter Point Projection Welding. The projections should have sufficient mass to heat a spot in the plane surface to welding temperature.

The KVA rating of the resistance welding machines for spot seam and projection welding normally varies between 5 to 500 KVA. Projection welding is generally used for projects with thicker materials around 0035 and thicker. Projection welding electrodes are also cooled as close to the weld face as design will permit.

Points of welding zone starting from 1 mm distance are shown Fig. These are typically V section with a 90 included angle. You can weld with 1 or even 05 gallonsminute but electrode wear will be noticeably higher.

Can the butt end of a 4MM 0156 mild steel wire be projection welded at 90 degrees to a piece of 4MM 0156 mild steel wire. Yes projection welding is very common with wire. In first step of welding especially in 0-1 sec temperature increases rapidly and when welding current is stopped it decreases in 2-3 sec indicating that cooling rate is very high because of high temperature dif ference between welding zone and.

Finally the FEM results are compared to experimental data to verify the simulation model and simulated results. Annular projections can be machined on components such as threaded bosses to provide a continuous leak tight seal with the sheet to which they are welded. And that would be the projection weld as well.

Spot welding is a type of electric resistance welding used to weld various sheet metal products through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. 3 for 1 mm sheet thickness. Some PW does not require a specific projection design as with cross-wire weldingmerely place the two wires in contact at 90 deg.

Work-pieces are held together. Brackets spigots and weld nuts to sheet metal where there is access from only one side and for making attachments to solid forged or machined parts. Developed to simulate the projection welding and predict the nugget diameter.

Short length T joints eg. Cross wire welding is done every day to make fencing and grating. Studs and nuts can have standard projection profiles eg.

Spot Welding Electrodes Welding Electrodes Spot Welding Welding Consumables

Resistance Welding Software For Simulation And Optimization Of Spot Projection Butt And Micro Welding

China Wholesale Hexagon Welding Nut Din 929 Stainless Steel Projection S Hexagon Steel Stainless

Schematic Of Shunting In Resistance Spot Welding Download Scientific Diagram

Simulated Temperature Distribution And Weld Nugget Formation For Spot Download Scientific Diagram

Resistance Welding Software For Simulation And Optimization Of Spot Projection Butt And Micro Welding

Heads Up It S Another Heads Up Display Hud Motorcycle Head Up Display Helmet Motorcycle Helmets

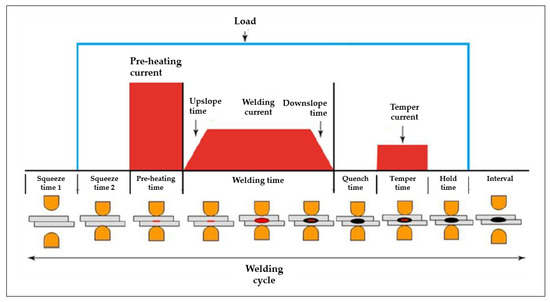

Metals Free Full Text Optimization Of The Resistance Spot Welding Process Of 22mnb5 Galvannealed Steel Using Response Surface Methodology And Global Criterion Method Based On Principal Components Analysis Html

0 comments:

Post a Comment