Please contact us for further information. To achieve the metallurgical bonding of two metals the distance between two surfaces has to be small enough to reach the range of the inter-atomic attractive forces 10.

Numerical Analysis Of High Speed Water Jet Spot Welding Using The Arbitrary Lagrangian Eulerian Ale Method Springerlink

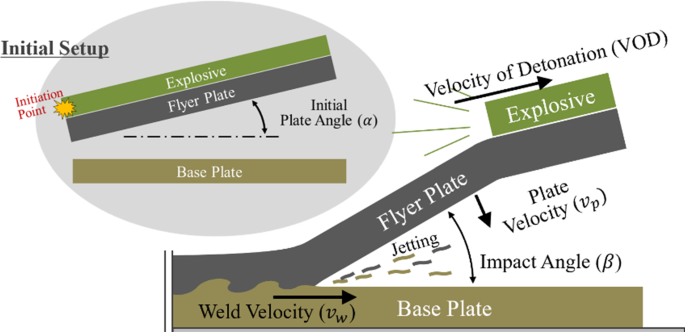

For welding to occur a jetting action is required at the collision interface.

Welding jetting meaning. A completed weld has the appearance of waves at the joint caused by a jetting action of metal between the plates. Binder jetting can be used for a variety of applications including 3D metal printing full colour prototypes and large scale ceramic moulds. Jetting refers to a situation where molten plastic fails to stick to the mold surface due to the speed of injection.

Depending on the environment and the type of surface the. These are also used to help break up a stubborn seabed for dredging operations. This cleans the metals and allows to pure metallic surfaces to join under extremely high pressure.

We have the versatility and skills it takes to undertake fabrication of a full assortment of piping structural steel and pressure vessels as needed. Additive manufacturing works by using a computer-aided design CAD or 3D object scanner that directs hardware to place material layer-by-layer to create precise geometric shapes. Claxtons variety of diver jetting lances provides an effective means of preparing surfaces for inspection maintenance or repair.

In manufacturing the Weld line or Knit line or Meld line is the line where two flow fronts meet when there is the inability of two. Weldability of metals Carbon and low-alloy steels are by far the most widely used materials in welded construction. This is different than traditional manufacturing methods that use milling machining shaping carving or various other methods to remove excess material.

Being fluid the molten plastic solidifies in a state that shows the wavy folds of the jet stream on the surface of the injection molded part. A - Steel surface largely covered with adhering mill scale but little if any rust. Binder Jetting is a sinter-based Additive Manufacturing technology which means the parts are printed as green parts with a certain polymer binder saturation.

However when flowing from a narrow area to a wide space if too fast it sometimes flies out in strips and flows without contacting the mold. To avoid jetting mould geometry and process conditions have to be altered to induce laminar flow within the cavity filling from the gate end as an unfolding melt front rather than an uncontrolled jet of melt. Kopakan is proud to offer these high quality welding services to our clients.

Jetting occurs when polymer melt is pushed at a high velocity through restrictive areas such as the nozzle runner or gate into open thicker areas without forming contact with the mold wall. After printing parts have to be debindered and sintered mostly in furnaces. Solid state welding is a group of welding processes which produces coalescence at temperatures essentially below the melting point of the base materials being joined without the addition of brazing filler metal.

The welding mechanism is most similar to that of explosion welding. Appearance Usually the molten resin flows in the form of a jet stream. The fact is drain jetting comes with many benefits and here are just some.

This group of welding processes includes cold welding diffusion. Magnetic pulse welding started in the early 1970s when the automotive industry began to use solid state welding. Magnetic pulse welding is a solid state welding process that uses magnetic forces to weld two workpieces together.

These lines usually occur around holes or obstructions. Gas Metal Arc Welding GMAW. These processes are sometimes erroneously called solid state bonding processes.

Drain rods may only increase efficiency by up to 30 and in a lot of cases the issue will be prolonged. The buckled snake-like jetting stream causes contact points to form between the folds of melt in the jet creating small-scale welds. This is referred to as jetting.

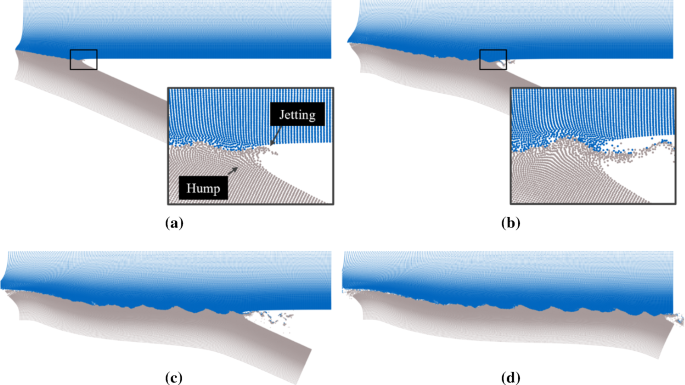

Direct Energy Deposition Direct energy depositioning uses focussed thermal energy such as an electric arc laser or electron beam to fuse wire or. In manufacturing the Weld line or Knit line or Meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to knit together or weld during the molding process. One of the most important conditions to achieve explosive welding is the formation of jetting at the collision point.

Drain jetting gets to the source of the issue and sorts it once and for all. It can get to the bottom of your problem much quicker. This jet is the product of the surfaces of the two pieces of metals colliding.

The biggest advantage using magnetic pulse welding is that the formation of brittle intermetallic. B - Steel surface which has begun to rust and from which mill scale has begun to flake. Of metal welding may occur.

Pressure may or may not be used. C - Steel surface on which the mill scale has rusted away or from which it can be scraped but with slight pitting under normal vision. 1 What is jetting.

Metals Free Full Text Influence Of Copper Interlayers On The Magnetic Pulse Welding Process Between Aluminum And Steel Html

A Semi Lagrangian Reproducing Kernel Particle Method With Particle Based Shock Algorithm For Explosive Welding Simulation Springerlink

A Semi Lagrangian Reproducing Kernel Particle Method With Particle Based Shock Algorithm For Explosive Welding Simulation Springerlink

Pdf Vaporizing Foil Actuator A Tool For Collision Welding

Metals Free Full Text Influence Of Copper Interlayers On The Magnetic Pulse Welding Process Between Aluminum And Steel Html

Explosive Welding Forming And Compaction 1983 John Pearson Pdf Explosive Material Metalworking

On The Complete Interface Development Of Al Cu Magnetic Pulse Welding Via Experimental Characterizations And Multiphysics Numerical Simulations Sciencedirect

Numerical Analysis Of High Speed Water Jet Spot Welding Using The Arbitrary Lagrangian Eulerian Ale Method Springerlink

0 comments:

Post a Comment