Imagine if three of those fall within 12 in. This is a weakness in the weld that typically is caused by when the travel speed is too high.

What Causes Undercut In Welding And Possible Remedies Arc Helmets

Feel free to contact me with any information to straighten me out.

Welding undercut meaning. When the base of metal melts away from the weld zone then a groove is formed in the shape of a notch then this type of defect is known as Undercut. Weld has undercut and the undercut is 116 in. Then the weld bead will be very peaked because of its extremely fast solidification.

Here are my ideas on this without going through all the AWS definitions Charts etc. The current is flowing one way from negative to positive. Deep for ¾ in.

This results in a feeble weld that is likely to have some cracks along the toes of the weld. Undercutting is common and costly. Undercutting leads to loss of money and productivity.

A weld replica is provided with an underfilled joint in which the edge of the base metal is undercut. Depth of Fusion - How deep your filler metal penetrates into the metal from the surface. Rel expression used to describe metaphorically a period of ignorance and spiritual crisis that precedes the communion with Divinity.

Did you know that even the most experienced welders can be victims of undercutting. It is a widespread problem and even the most experienced welders sometimes face this issue. This results in an overall reduction of the strength of your weld and workpieces.

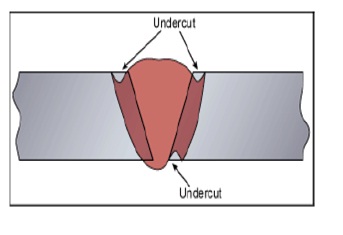

Direct Current - DC welding is the smoothest welding producing the least amount of spatter. Undercutting is a groove that develops in the base metal near the toe or root of the weld. Weld is undercut at two places.

The undercut is 116 in. In welding undercutting refers to when the cross sectional thickness of base material is reduced by a weld. Even the most experienced welders fall victim to undercutting so its not just novices.

In welding undercutting is when the weld reduces the cross-sectional thickness of the base metal. Weld is part of a 3-on-6 intermittent fillet weld. This type of defect reduces the strength of the weld and workpieces.

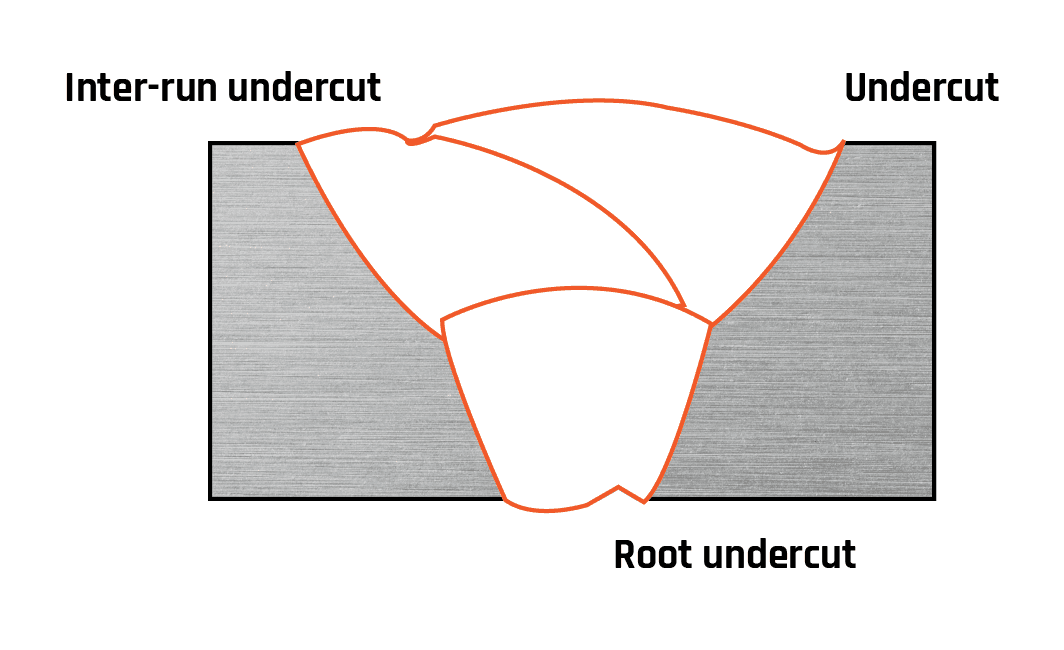

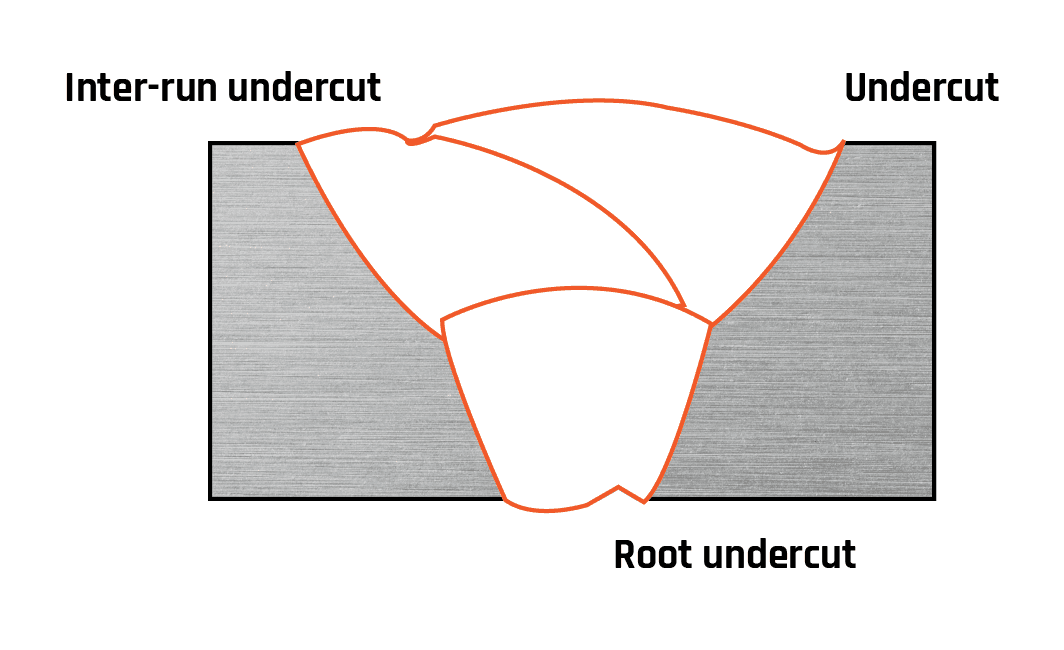

Undercutting in welding is a situation where the weld reduces the cross-sectional thickness of your base material. Main defects are Longitudinal Cracks Porosity Slag Inclusion and the Cardinal Sin of weldingUndercut. This leaves a drain-like impression along the length of the weld.

Instead of the edges of the weld looking flush there are small to large divots where the weld has dug into the base metal. Undercutting is when the edge of a weld has an inverse U shape. Undercut is when the edges of a weld have cut into the base material.

What is Undercutting in Welding Undercutting is a crater or groove that occurs near the toe of the weld. Undercutting happens when the weld metal fails to fill in that grooved area. Undercut in fact reduces the cross-sectional area of welded joints.

In a larger meaning it is used when refering to having a hard time going through a phase of pessimism sadness failure etc. One reason for this defect is excessive current causing the edges of the joint to melt and drain into the weld. The net stress increase in the loaded joints is equivalent to the reduction of permissible design capacity.

Significance of Weld Undercut Weld undercut can cause a welded joint to be unfit for service through three mechanisms. The toe of the weld is where the weld bead meets the base metal. Undercutting often reduces the overall strength of a weld as well as work pieces.

A groove in simpler terms is a long and narrow cut in hard material. The result of which is a weak weld that is prone to cracking along the toes. Reduction of cross-sectional area.

Undercutting in welding occurs when the weld metal failed to fill-in the grooved area. Undercut or undercutting in welding is the term given to a groove that develops at the base or root of the metal.

Welding Defects Classification Causes And Remedies Welding Ndt

What Is Undercutting In Welding Causes And Prevention

7 Most Common Welding Defects Causes And Remedies Slv

Undercut Meaning In Welding John Page Coiffure

The Most Common Welding Defects Causes And Remedies Technoweld

What Is Meaning Of Under Cut In Welding Marinegyaan

Pittsburgh Cwi Seminar Nightmare Undercut Vs Underfill

What Is Undercutting In Welding How Can It Be Prevented Quora

Ppt Defects And Discontinuities Powerpoint Presentation Free Download Id 1764968

0 comments:

Post a Comment