The removal of heat tint from stainless steel fabrications using brush-on pastes or gels spray or immersion acid pickling or electrolytic methods will normally be satisfactory. The best way to clean stainless steel after welding is through a process called electropolishing.

How To Clean Stainless Steel After Welding Welding Headquarters

However the choice of method depends largely on the scope of the problem.

How to clean up stainless steel after welding. Electropolishing not only clears the surface from stains but it. Pickling paste has long been a standard way to remove heat tint from stainless steel welds. Instead another solvent should be applied and then a stainless steel wire brush should be used to clean the weld.

Dirt on the surface of your stainless steel takes away its appealing shine. Contamination occurs when stainless steel is subject to sparks or particles from nearby welding cutting drilling or grinding of carbon steel. High temperatures A less common form of rusting occurs after the stainless steel has been exposed to very high temperatures in the 7501550F range.

Mechanical polishing using a surface conditioning pad works nicely to remove the color. Cleaning stainless steel TIG welds - YouTube. The removal of heat tint from stainless steel fabrications using brush-on pastes or gels spray or immersion acid pickling or electrolytic methods will normally be satisfactory.

This contains moisture and oil contaminants that will introduce new impurities to the surface. Stands with green knife makers rouge and a wire wheel with004 wires on it. It will also brighten the surface.

When stainless steel is heated to welding temperatures it turns lots of pretty colors - gold red purple blue - depending on the temperatures. And that includes stainless steel delivered straight from the supplier. These look nice but if you want your stainless steel to look like stainless again a polishing step is required.

Electropolishing not only clears the surface from stains but it also helps the metal become properly passivated. This process involves the oxidation of an acidic electrolyte on a metal surface with the help of electricity. Cliff Kusch electropolishing shop -.

The best way to clean stainless steel after welding is through a process called electropolishing. It worked fine but you had to load the wire wheel with rouge or it would just frost the stainless. Unlike grinding this cleaning method will successfully remove all.

Electropolishing will also remove heat discoloration and render the surface more corrosion resistant then passivation or pickling alone. It doesnt matter if youre welding MIG TIG welding with flux core wire or stick welding clean off the metal surface. You probably know this but you shouldnt use a carbon steel brush on aluminum since little particles of it will find their way into the weld and contaiminate it.

This process involves the oxidation of an acidic electrolyte on a metal surface with the help of electricity. Like SJones stated the stainless steel is not immune to soil corrosion. That may well prompt pre weld grinding to clean your stainless steel.

The paste made from hydrofluoric acid and nitric acid is applied to the affected areas using a brush or spray then later removed and neutralized with a neutralizing agent. Click to read more about these methods. If your welds are very clean as you say with no wire brushing and you only need to remove the heat burnish then just use PrepEtch solution from Home Depot and wash thoroughly with water.

The nitric acid used in these treatments will also leave the steel surface in the passive condition. The nitric acid used in these treatments will also leave the steel surface in the passive condition. The electrochemical process will not only remove imperfections on the surface after welding but it will also restore the oxide layer that returns stainless steel back to its normal passive state.

It does make life a little easier depending on how dirty it is. After a joint is welded do not use compressed air to blow away excess material from the joint. Joint Clean-up After a Weld.

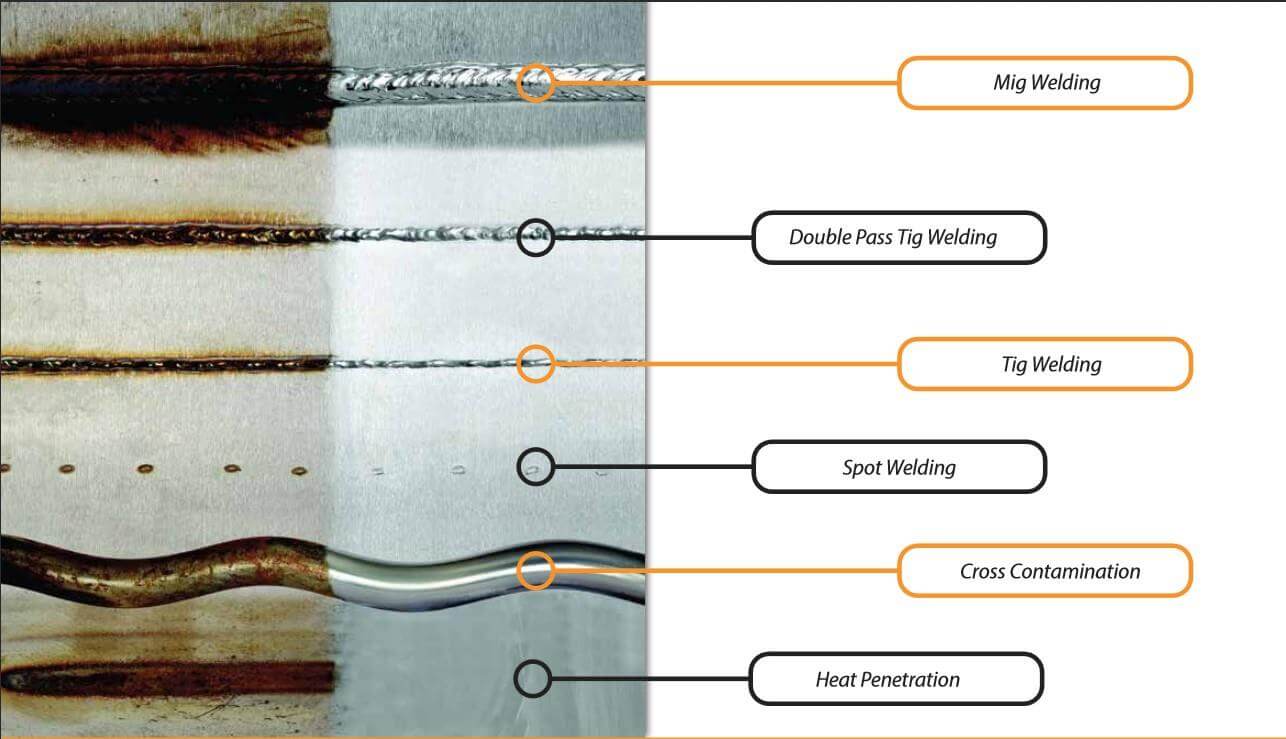

I would wrap the plate with appropriate tape to insulate from soild and moisture. Several methods are commonly used to remove discoloration on stainless steel after welding electrochemical cleaning chemical pickling and mechanical grinding brushing are just few of them. Stainless wire brush right after welding.

Its best to use a flap disc to clean the stainless steel after using a solvent wipe to remove any oil. About fifteen years ago when I worked for a medical goods manufacturer We would polish out the welds on the stainless steel IV.

Will This Stainless Steel Weld Rust

How To Clean Stainless Steel After Welding Welding Headquarters

Why Does Stainless Steel Rust After Welding Cougartron

Welding Stainless Steel A Quick Guide Weld Guru

Electrochemical Weld Cleaning The Fastest And Safest Way To Clean Stainless Steel Welds Cougartron

Diy Stainless Steel Weld Cleaning Electropolishing 6 Steps With Pictures Instructables

7 Ways To Finish Stainless Steel After Welding Heat Tint Occurs Weldingboss Com

How To Remove Heat Tints Discoloration After Welding Cougartron

How To Finish A Welded Stainless Steel Tube In 3 Steps Polish Finish Youtube

0 comments:

Post a Comment