On the number of operators. Ensure torch tips are cleaned as per manufacturers recommendations.

Hazards In Welding And Cutting Industrial Health Safety Review

Welding is usually used on metals and thermoplastics but can also be used on wood.

Welding cutting operation. Welding Cutting Hazards Welding and Cutting operations present a variety of hazards not only to those carrying out the operation but in many instances to others in the vicinity. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. General Welding and Cutting Controls.

Many cutting and welding operations produce toxic fumes and gases. The oxy-fuel process utilizes a flame to generate heat for cutting welding and brazing. Companies that weld and cut should take specific steps to increase safety and minimize the risk of torch fires.

Welding and cutting which accounts for 1 percent of structure fires and 4 percent of nonhousehold property damage is the most dangerous type of hot work according to the National Fire Protection Association NFPA. Oxy-fuel cutting OFC is. Dust or fume masks do not Provide adequate protection.

The completed welded joint may be. Operation and maintenance of the welding and cutting equipment should conform to regulations from Federal State County and City. Leave the work area in a safe clean tidy condition.

It var-ies with the size of work area. A firebrick top workbench is recommended for cutting on. In the workshop there are a number of hazards specific to welding or cutting and others of a more general nature which may also be present in the fabrication.

For details of safety information refer to provisions of ANSI standard Z491 Safety in Welding Cutting and AWS manual C42C42M-09 Recommended Practices for Safe Oxyfuel Gas Cutting Torch Operation. Care must be taken to avoid the contact of the flame with any combustible substances. Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool.

Provide enough ventilation wherever welding and cutting are performed. For metal cutting operation gas or oxygen cutting is extensively used now-a-days in industry. If you have to cut or weld materials or use fluxes containing fluorine compounds zinc lead beryllium cadmium mercury or other toxic materials special ventilation and respiratory protection will be needed.

Ensure that you have adequate. Welding or cutting in. This may happen when the torch is held too close to the workpiece or if the nozzle is partly blocked.

Fire code permits are required for all welding and cutting operations. This checklist must be used with the Welding Cutting and Brazing--General Requirements checklist. In a location where adequate exhaust ventilation is not possible welding and cutting can be carried out safely by personnel wearing suitable respiration protection.

The degree and type of ventilation will depend on the specific welding and cutting operation. APrior to beginning welding or cutting operations workers must check that the cylinders regulators backflow prevention device flame arrestors hoses clamps and torches are in good working condition. Welding and cutting operations should be restricted to workers who have been properly trained.

And on the types of materials. Apart from using hacksaw power saw chisels etc. The regulations cited apply only to private employers and their employees unless adopted by a State agency and applied to other groups such as public employees.

The flame may go out or it may reignite at the nozzle. Proper venti-lation will protect the operator from the evolving noxious fumes and gases. BOil or grease must not come into contact with.

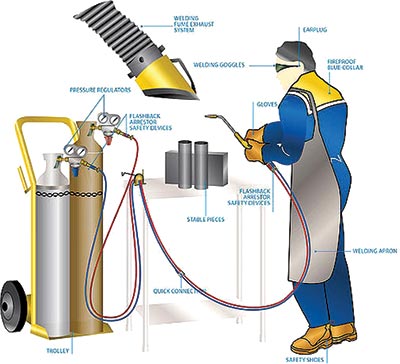

The diagram above illustrates the basic set-up of an oxy-acetylene cutting operation. It applies to operations involving oxygen-fuel gas welding and cutting. Permits are obtained from the local fire official.

When the welding cutting or heating operation is such that normal fire prevention precautions are not sufficient additional personnel must be assigned to guard against fire while the actual welding cutting or heating operation is being performed and for a sufficient period of time after completion of the work to ensure that no possibility of fire exists. Whenever possible hot work should be performed in a properly. Its particularly effective for gouging holes into aluminum or stainless steel.

Safety in gas welding cutting and similar processes Page 6 of 11 Backfires and flashbacks Backfires A backfire is when the flame burns back into the torch often with a sharp bang. Plasma Cutting works on all metals ferrous and non-ferrous thin or thick.

Oxy Gas Welding Cutting Oerlikon

Cutting Grinding Tools For Welding Welders Universe

Solutions For Non Alloyed Steels Welding And Cutting Applications Oerlikon

Oxy Gas Welding Cutting Saf Fro

Cutting Grinding Tools For Welding Welders Universe

Cutting And Welding Technologies

Preventing Torch Fires In Welding And Cutting Operations

Safety Precautions For Welding Cutting And Brazing Hazards

Chapter 10 Cutting Processes Metal Arts Press

0 comments:

Post a Comment