It also offers good strength levels combined with an excellent hot formability. Argon and Carbon Dioxide mix.

Best Offer On C46200 Naval Brass Tubes Buy C46200 Naval Brass Tubes C46200 Naval Brass Tubes All Grade C46200 Naval Brass Tubes All Size

If the surface of the metal is not clean the filler metal will not flow smoothly and evenly over the weld area.

Welding naval brass. Naval Brass is a 6040 copper zinc alloy to which about 1 of tin has been added to improve the corrosion resistance particularly to dezincification. Similar in appearance to naval brass and its welding processes bronze casting alloys are another option. Anything below half an inch will pose serious issues especially when you are using high penetration welders like a TIG welding machine.

The alloy is a two phase alpha-beta brass hence has reasonably high strength with lower ductility than the single phase 7030 or alpha brass. Many of these alloys like the brasses are alloyed with lead to improve machinability. The generation of zinc fume results in welds which are likely to be porous and consequently unacceptable particularly if autogenous welding is attempted.

There are also many industrial applications such as welding rods condenser plates structural uses valve stems balls heat exchanger tubes. The alloy is a two phase alpha-beta brass hence has reasonably high strength with lower ductility than the single phase 7030 or alpha brass. Naval Brass C46400 is nominally composed of 60 copper 392 zinc and 08 tin.

As the name implies naval brass has extensive marine application and can be found where strength and corrosion. When welding naval brass you want to be sure to use an inert shielding gas. Using pulse can help too.

Naval Brass is a 6040 copper zinc alloy to which about 1 of tin has been added to improve the corrosion resistance particularly to dezincification. Carbon steel Vs Naval Brass welding I had specified for an exchnager AEL type Admiralty tubes for cooling water Naval brass for tube sheet and CS for Shell Naphtha will there be any problem with the tube sheet to shell joint welding or for tubesheet to tube joint expecting your reply regards NSBabu. The next group of alloys is the bronzes.

Inhibited 44300 Admiralty Brass has. Below are a few options you have for inert shielding gasses. Can naval brass be welded.

Brass 443 tubes have long been used in heat exchangers and condensers because of C443s good corrosion resistance and excellent heat transfer characteristics. The trick to getting it to weld is to use just enough heat to melt the rod if u see zinc and such sweating out of the pores back down a bit on heat. Naval brass is weldable using gas-shielded arc processes eg.

The gas used for shielding will vary according to whether welding is manual or automatic and the thickness of the section. As is typical of brass alloys with the duplex alpha beta structure C46400 has good strength and rigidity. In this project the Naval Brass plates C46400 are welded by Friction Stir Welding process FSW.

C46400 Naval Brass is copper alloyed with zinc and tin to provide improved strength corrosion resistance and machinability. The selection of the proper brazing filler metal depends on the types of base metals. In the case of brass and other mild steel like aluminum it is generally fine to weld them for as long as they are thick enough to actually handle the process.

Due to its rather high zinc content around 39 in respect to copper around 60 naval brass is rather difficult to weld and requires extra precaution in handling because it tends to release toxic copper zinc fumes. Although the carbon-arc method has been employed ro weld Naval Brass with copper-zinc filler rods of the low-fuming type this method is generaUy employed with zinc-free rods such as silicon aluminum or phosphor bronzes. The most commonly used are brass brazing alloy and naval brass.

The addition of tin is made for extra corrosion resistance in seawater and other mildly aggressive environments. This will help protect the electrode and weld pool from becoming contaminated by oxygen. Friction stir welding allows achieving high quality welding when compared to brazing.

Hence its never recommended to use manual metal arc welding processes when handling naval brass. Welding backward can work better too some brass alloys are very dirty. Be sure to do your research on how to weld naval brass.

These may be alloyed with tin generally described as phosphor bronze silicon or aluminium. Sometimes using pulse and pulsing the foot pedal works too. The alloys most commonly welded are aluminum brass 76 copper 22 zinc 2 aluminum Admiralty brass 70 copper 29 zinc 1 tin and Naval brass 62 copper 3675 zinc 125 tin.

Welding using the manual metal arc MMA process is not recommended for naval brass or any other zinc-bearing copper alloy. By substituting tin for an equal quantity of zinc a high corrosion resistance to seawater is achieved. Flux Proper fluxing is essential in braze welding.

C44300 Admiralty Brass also sometimes referred to as Arsenical Brass is copper that is alloyed with tin and zinc. Naval brass is used in propeller shafts marine hardware decorative fittings shafting propeller shafts and turn buckles. Instead gas-shielded arc processes such as MIG.

C46400 Naval Brass is classed as naval brass and is a 60 copper 40 zinc with 1 tin alloy. C46500 is a brass with high ductility high electrical and thermal conductivity high impact strength good creep resistance ease of welding and low volatility under high vacuum. This can be largely dealt with by annealing the welded item at 260-300C.

Naval Brass Rounds Dolphin Maritime

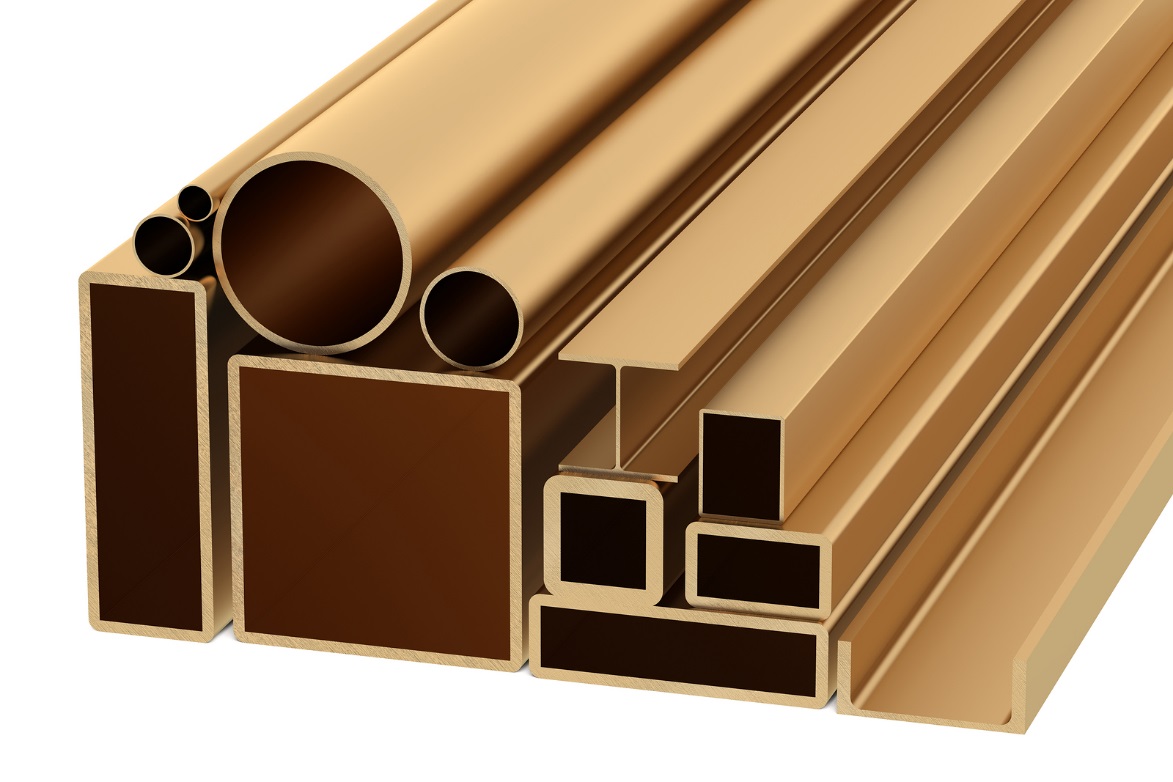

Naval Brass Hollow Rods Products Naval Brass Lead Free Naval Brass Medium Lead Naval Brass High Lead

China Free Samples Copper Zinc Alloy Brazing Rod Brass Welding Rod China Brass Welding Rod

How To Weld Brass Welding Headquarters

What You Need To Know About Naval Brass Before Putting It To Work

C46400 Naval Brass Non Ferrous Metal Experts Marmetal Industries

![]()

Cda 464 Naval Brass Uninhibited Non Ferrous Metal Works

How To Weld Brass Welding Headquarters

0 comments:

Post a Comment