Pressure fuses the materials. Heat is concentrated at the projections which permits the welding of heavier sections or the closer spacing of welds.

Welding Solution C D Projection Welding Machine

Projection welding is a suitable process for a number of metals including low carbon steel stainless steel and aluminum.

Welding projection means. By providing a projection on the surface of one of the workpieces weld current and force can be focused into the small area of the projection to produce heat at the desired weld location. 2 The size of circular projection welds shall be designated as the diameter of the weld expressed in fractions or in decimals in hundredths of an inch and shall be shown with or without inch marks to the left of the weld symbol fig. Projection weld fasteners in general generate more precise and reliable welds as compared to spot weld fasteners.

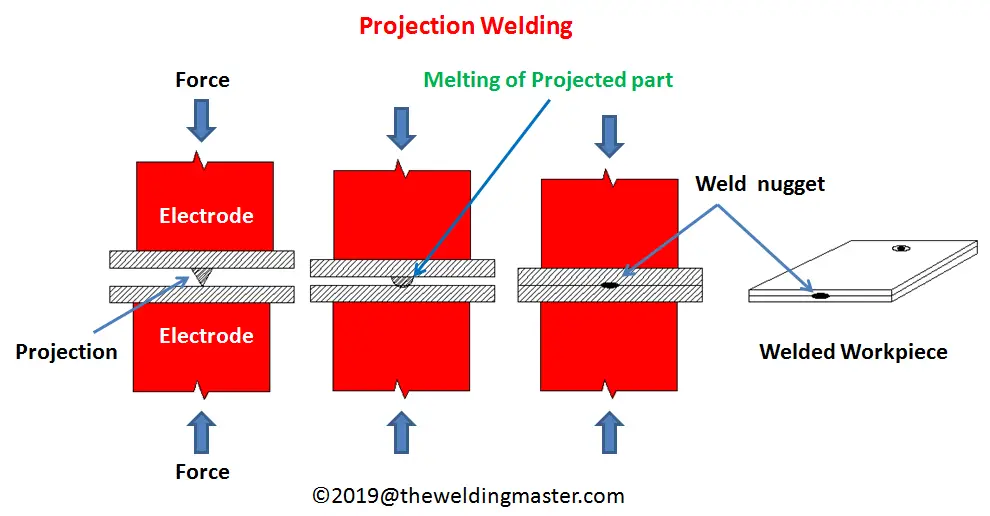

This resistance-welding process employs projections formed onto one of the parts. Projection welding is one kind of resistance weld where the shape or design of the part is used to make subtle point contacts to concentrate the current during welding. 1 Projection welds must be dimensioned by strength.

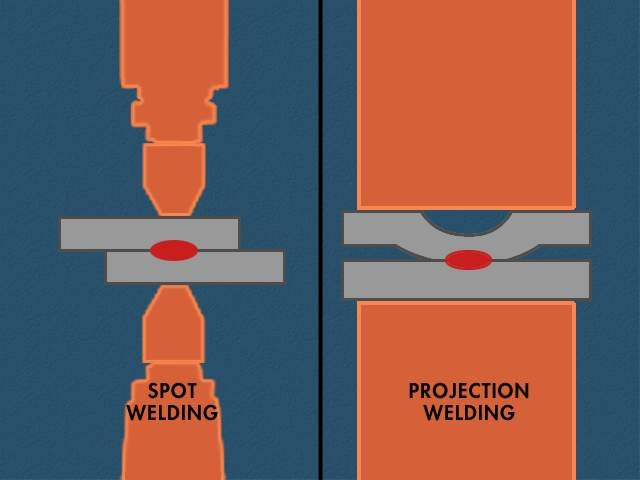

This means that gas pocket or inclusions are present in the welded material. This process does have a couple of downsides such as extra steps in the production process and limitations. Projection welding is a modification of spot welding in which the weld is localized by means of raised sections or projections on one or both of the workpieces to be joined.

The increased efficiency means that sheet thicknesses of up to 0125 inch 3 mm can be successfully welded. Proper cleaning and the prevention of contaminants from entering the weld zone. A resistance welding made by joining embossments on one or both of the parts being welded.

Circular projection welds may be dimensioned by size. Size of Projection Welds. Fasteners meant for hermetic seals are designed with ring projections contained on the flange of the weld nut.

Reducing welding speed to allow time for gas to escape. Definition of projection welding. In general they have relatively short weld times and perform very well as documented.

There are cases in which the circumstances in manufacturing are not ideal and variations from the standard are necessary. Brackets spigots and weld nuts to sheet metal where there is access from only one side and for making attachments to solid forged or machined parts. One of the main differences between conventional sheet-to-sheet resistance welding and projection welding is that projection welding is a dynamic process involving considerable movement of the upper electrode.

Projection welding is a type of resistance welding that focuses current and force to a single point or line at the beginning of a weld. A very important factor is that the full force must be maintained on the projections as they collapse. Burrs in projection welding be it Capacitive Discharge AC or MFDC resistance welding are caused by several factors.

This welding technique creates spot or projection welds in sequence with pressure applied to the weld made by multiple electrodes. Projection Welding Projections low thermal-mass islands are one method of insuring proper heat balance in difficult spot-welding applications when there the parts to be welded vary in size by 51. Short length T joints eg.

Another is the weld interface may have been overheated. Improve welding techniques such as preheating of the weld area or an increase in the rate of heat input. Projection welding is a resistance welding process of joining two sheets or a sheet and a thick component or a small component like nut to a big body like automotive chasis by making raised portions or projections on one of the components where weld nugget is required to be made.

Proper selection of electrode and filler materials. However spot welding fasteners have their own uses. Heat is concentrated at the projections which permits the welding of heavier sections or the closer spacing of welds.

These fasteners work without the use of projections. Mostly in almost all applications with various small projections are molded on single parts surfaces which need to weld. Projection welding is an ideal method of fastening attachments eg.

The projections which can have single or multiple embosses of various shapes concentrate the welding current exactly where the joints need to form. 14 or 15 can be made by forming projections in. Where the design calls for tighter weld spacing consider using projection welding.

Projection welding is a modification of spot welding in which the weld is localized by means of raised sections or projections on one or both of the workpieces to be joined. Projection welding parameters are readily available in published weld schedules referenced below. One is the inability to contain the molten weld nugget as it is forms.

What Are The Differences Between Projection Welding And Spot Welding Quora

Projection Welding Ppt Video Online Download

What Is A Projection Weld How To Resistance Weld

Projection Welding Ppt Video Online Download

Projection Weld Symbols Diagrams Guide Weld Guru

Resistance Welding Is A Pressure Welding Technique Using

What Is Projection Welding Working Principle Advantages Disadvantages And Application The Welding Master

Projection Weld Symbols Diagrams Guide Weld Guru

What Is Projection Welding Working Principle Advantages Disadvantages And Application The Welding Master

0 comments:

Post a Comment