The principle of resistance welding is the Joule heating law where the heat Q is generated depending on three basic factors as expressed in the following formula. Resistance welding in British English noun a welding technique in which the parts to be joined are held together under pressure and heat is produced by passing a current through the contact resistance formed between the two surfaces.

Resistance Spot Welding Cycle F Is The Forging Force And I Is The Download Scientific Diagram

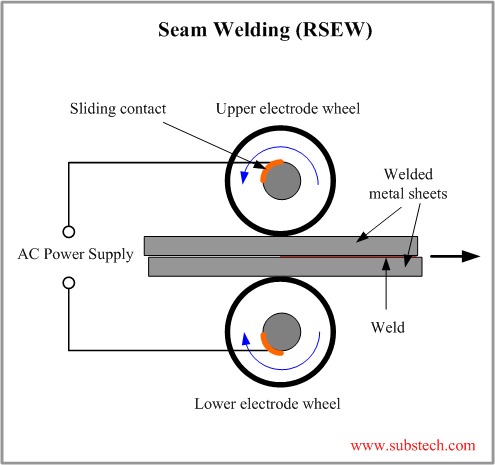

Termination of Intermittent Resistance Seam Welding.

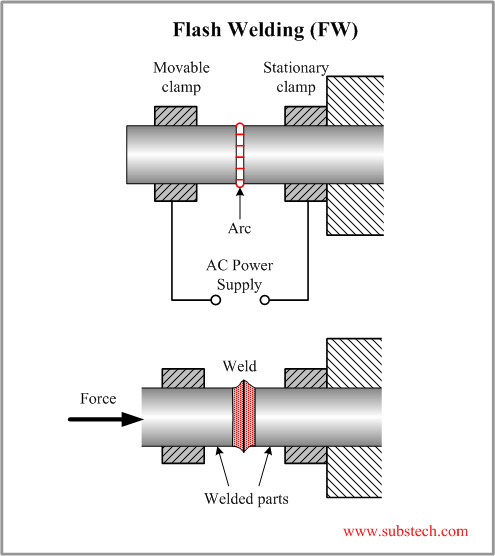

Welding resistance meaning. Resistance welding is a thermo-electric process in which heat is generated at the interface of the parts to be joined by passing an electrical current through the parts for a precisely controlled time. Resistance welding requires neither additional material or holes in the metal. Resistance welding synonyms resistance welding pronunciation resistance welding translation English dictionary definition of resistance welding.

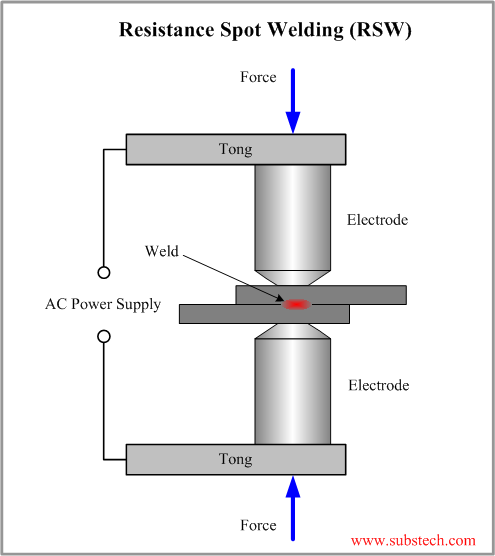

In the last session we had discussed gas welding process and arc welding process and whereas in todays session we will discuss on Resistance Spot Welding along with its Definition Construction Working Principle Applications Defects Advantages and Disadvantages. Welding that uses heat from an electrical current passed through the metal. It is a thermo-electric process in which heat is generated at the interface surfaces of welding plates due to electric resistance and a controlled low pressure is applied to these plates to create a weld joint.

How is a resistance weld made. Resistance welding is an open-air fusion bonding technique that employs an embedded heating element at the interface to heat via Joule heating the interface between adherends as shown in Figure 4. Felicia Dye A welding mask protects a welders eyes and face.

Welding that uses heat from an electrical current passed through the metal. American Heritage Dictionary of the. It works by contacting copper alloy electrodes to the sheet surfaces whereby pressure and electric.

Resistance welding can be defined as. The key advantage of resistance welding is that no other materials are needed to create the bond which makes this process extremely cost effective. The two pieces of metal to be joined are squeezed together by the electrodes on the welding machine so they are in good electrical contact.

Pitch of Resistance Seam Welds. The weld is made by the combination of the heat pressure and time. Resistance welding noun a welding technique in which the parts to be joined are held together under pressure and heat is produced by passing a current through the contact resistance formed between the two surfaces.

Resistance welding is one of the oldest of the electric welding process is used by industry today. Where I is the current passing through the metal combination R is the resistance of the base metals and the contact interfaces and t is the durationtime of the current flow. The heat required for melting and joining of the plates obtained through the.

It is important for the heating element to be compatible with the. Then electric current is passed through them. Spot welding also known as resistance spot welding is a resistance welding process.

Resistance welding is a liquid state welding process in which the metal to metal joint created in liquid or molten state. Resistance welding is the joining of metals by applying pressure and passing current for a length of time through the metal area which is to be joined. Definition of Resistance Spot Welding.

Such processes usually pertain to connecting metals but the term resistance welding may also be used in plastic bondingThis type of welding is regarded as quick and efficient when done properly. It is a liquid state welding method where the metal-to-metal joint can be formed within a liquid state otherwise molten state. Are worked on the same principle of heat generation due to electric resistance.

When intermittent resistance seam welding is used by itself the symbol indicates that increments are located at the. Resistance welding refers to processes that use electrically generated heat and pressure to create bonds between materials. This welding process is used primarily for welding two or more metal sheets together by applying pressure and heat from an electric current to the weld area.

What does resistance-welding mean. All resistance welding spot welding seam welding projection welding etc. The pitch of intermittent resistance seam welding shall be designated as the distance between centers of the weld increments and must be shown to the right of the length dimension fig.

What Is Erw Steel Pipe Www Pipelinedubai Com

Projection Welding Machine Meaning

Resistance Welding An Overview Sciencedirect Topics

Resistance Welding Rw Substech

Resistance Welding An Overview Sciencedirect Topics

Resistance Welding Rw Substech

Projection Welding Machine Meaning

Resistance Welding Rw Substech

Why Use Multiple Impulse Resistance Welding

0 comments:

Post a Comment