At this distance the capture velocity is 100 feet per minute which is what Air Quality Engineering seeks as the maximum because per the American Welding Society air velocities above 100 feet per minute at the arc may draw too much of the shielding gas from the weld. LEV is the most effective means of removing contaminants from the welders breathing zone.

Please Read This Before Using Presentation L L

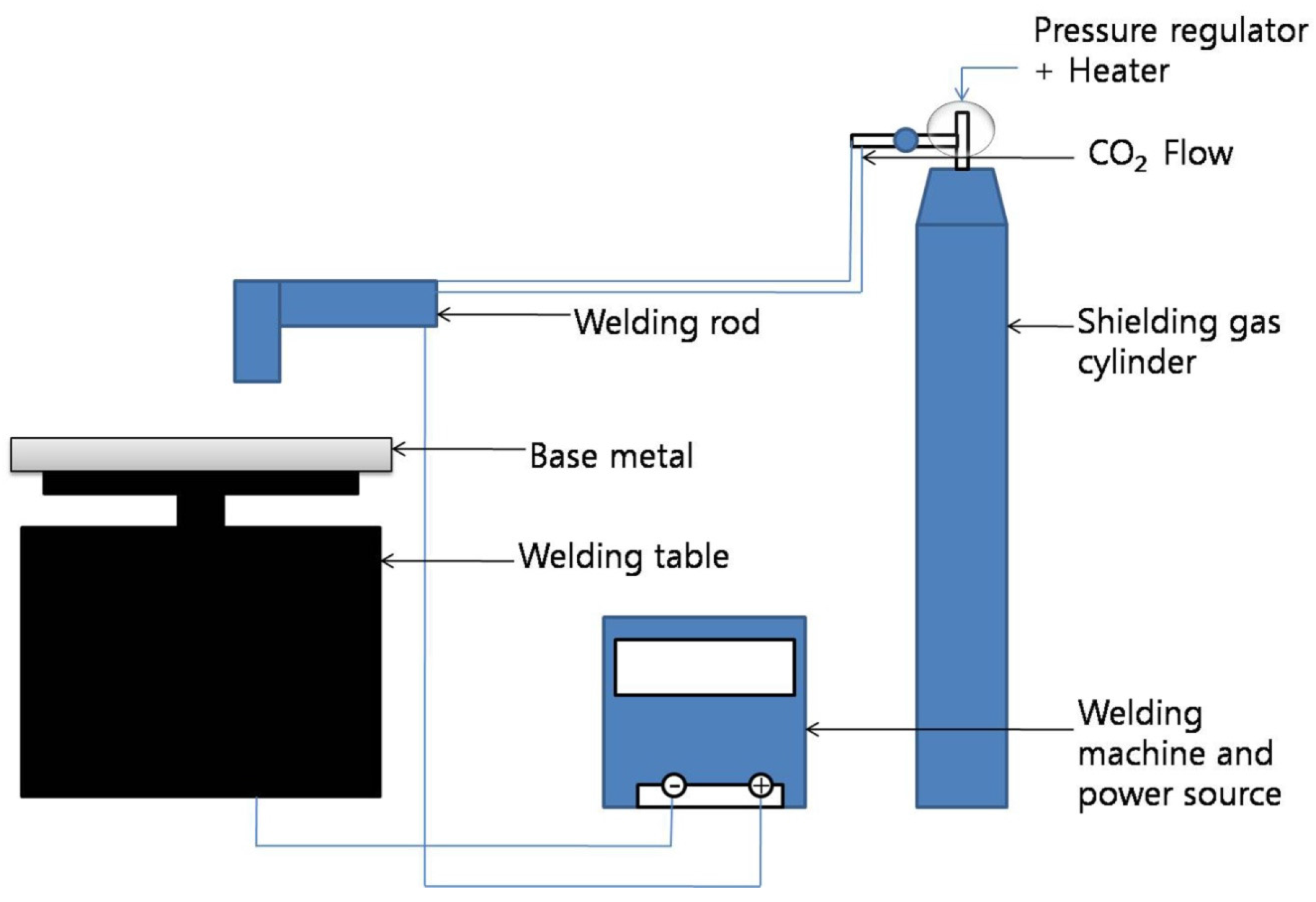

Welding system The welding power source was a Digiwave Air Liquide.

Capture velocity for welding fumes. Lower End of Range Upper End of Range 1. The velocity in the 6 duct were good to provide a capture velocity 172 fpm at the 6 distance. LEV performance can be tested for comparison to the capture velocity range 05ms to 1ms as described in the HSE guidance Controlling airborne contaminants at work PDF as.

Vacuum nozzle at the arc Fume Hoods. CalOSHA requires capture velocity for welding fumes at least 100fpm. Welding fumes are classified as Group 2B possibly carcinogenic and this prompts to the implementation of local exhaust ventilation LEV.

They can keep contaminants below allowable limits. E velocity induced by capture at the pollutant emis-. The capturing air velocity in a distance x from an exhaust outlet can be calculated as.

At a capture velocity of faster than 03 ms the fume concentration at welders breathing zone was reduced to a level below the limit values. The proper choice of values depends on several factors. Released at high initial velocity into zone of very rapid air motion.

Fume extraction guns use fume capture nozzles built into the gun tube and handle. The local exhaust ventilation configurations for welding vary depending on whether a fixed site for the work exists or whether a mobile hood is. Recommended capture velocities for exterior hoods designed to control welding fumes are in the range of 100170 fpm 66.

Therefore no repositioning is required since the suction automatically follows the arc. As it was mentioned in the Flynn MR and Susis6 paper published in the Annual Occupational Hygiene4 Although LEV can produce. The table below shows weld fumes generation ratios for the various welding methods.

Suction nozzles are positioned near the weld typically with magnets and commonly use capture distances of less than four inches. The air velocity induced in the welding zone was. Typically a source capture hood should be placed no further than one diameter of the hood diameter of a circular hood.

An on-gun extraction system was also evaluated. Capture device ducting and a fan. 100 feet per minute capture velocity Preliminary data support that this reduces exposure to less than 01 mgm3 but may be above 002 mgm3.

Vc q 4 π x2 vo A 12 x2 vo π d2 48 x2 1 where. Abrasive blasting tumbling 500 - 2000 In each category above a range of capture velocity is shown. This information can be used to determine the amount of fume being generated and consequently the air velocity needed to adequately capture those fumes 15.

This was to be achieved by the addition of. ACGIH TLV and Japan Welding Engineering Society CLV. Exposures to Welding Fumes The Annals of Occupational Hygiene Volume 55 Issue 3 1 April 2011 Pages 305318.

Q air volume flow m3s ft3s A duct area m2 ft2 vc capture air velocity in distance x from exhaust outlet ms fts. The capture devices remove fumes and gases at their source. LEV devices must be capable of maintaining a velocity of 100 fpm toward the air intake.

Weld metal porosity during gas shielded arc welding using parameters defined in Phase 1. Source extraction or local exhaust ventilation LEV is a mechanical device used to capture welding fumes at or near the arc and filters contaminants out of the air. Fixed or moveable capture devices are placed near or around the work.

One or more of the following capture devices are recommended. N Phase 3 was to measure capture efficiencies for a range of different LEV hoods positioned at various distances and orientations to the welding arc whilst monitoring weld metal integrity. By increasing capture velocity further from the face contaminant capture could take place at distances more convenient to the circular slotted-hood operator while maintaining adequate suction.

Achieve increases in capture velocity at an upstream distance equal to the diameter of the hood 11 inches.

Count Based Size Distribution Of A Welding Fumes And B Nacl Download Scientific Diagram

Welding Fumes V What Are Welding Fumes V

Atmosphere Free Full Text Indirect Prediction Of Welding Fume Diffusion Inside A Room Using Computational Fluid Dynamics Html

Typical Bright Field Tem Image At 200kx Showing Welding Fumes With A Download Scientific Diagram

Welding Fumes V What Are Welding Fumes V

Count Based Size Distribution Of A Welding Fumes And B Nacl Download Scientific Diagram

Ijerph Free Full Text Welding Fumes A Risk Factor For Lung Diseases Html

0 comments:

Post a Comment