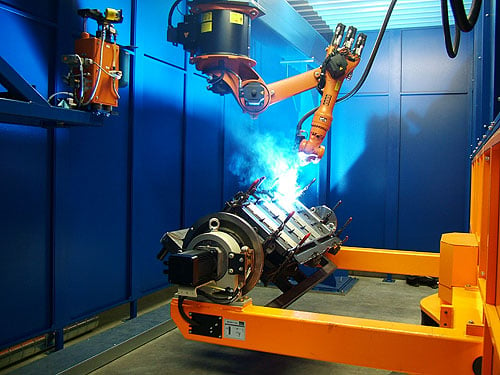

The used arc welding robots have been completely reconditioned and are sold at a reduced price. Applications from the industry with QuellTech laser measurement technology.

5 Factors To Consider Before Moving To A Robotic Welding Process

In this article well take a closer look at exactly how welding works.

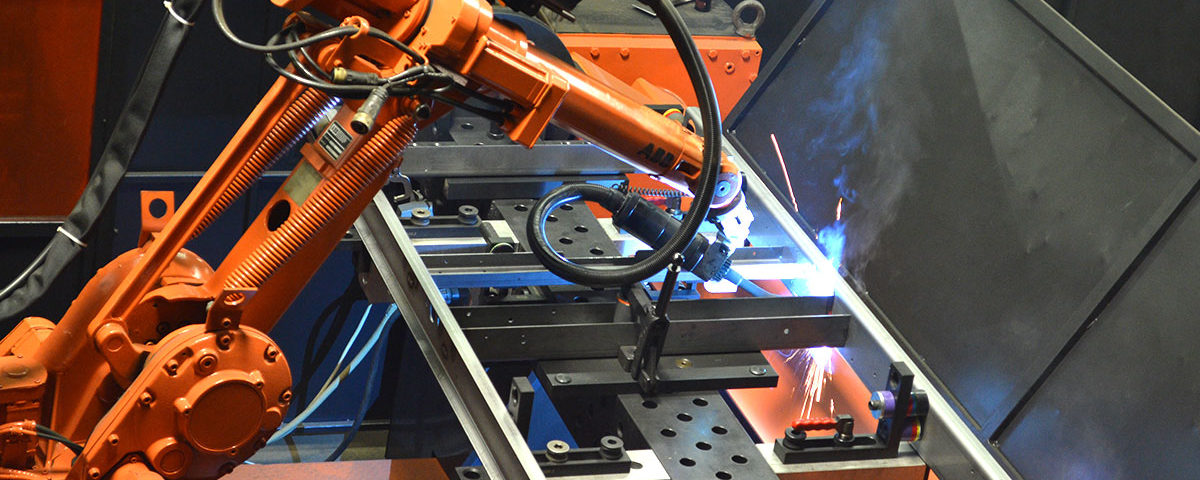

How do welding robots work. Welding on the other hand cuts out the middleman and joins the original pieces directly to each other. A wire feeder sends the filler wire to the robot as it needs it for a welding job. A positioner with the appropriate handling capacity and the welding robot itself.

These programs move the welding robot and dictate the movement of the torch on the end of its arm placing it exactly where it needs to perform tasks. Robotics control the movement of a rotating wrist in space. Ad Quelltech Laser Sensor Technology.

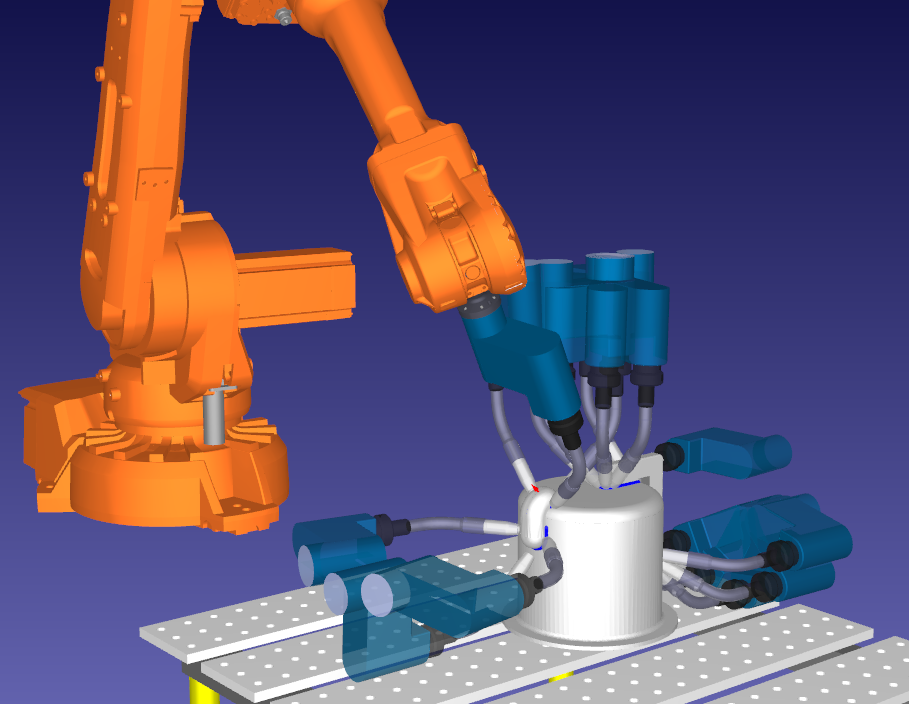

A robotic welding system may perform more repeatably than a manual welder because of the monotony of the task. A good robot program will prevent the robot from performing exaggerated positionspostures and balance the motion of the torch orientation with the robot arm position. A robot welding unit also called a robot welding cell consists of several components working together to weld pieces.

Find more information here. Because the temperatures reach thousands of degrees using robots for this process keeps people safer. Becoming a highly skilled welder takes years of experience training and practice whereas a robotic welding cell operator only has to load the part press the appropriate buttons to activate the machine and then unload the part.

Processes such as gas metal arc welding while often automated are not necessarily equivalent to robot welding since a human operator sometimes prepares the materials to be welded. A description of some of these welding robots. The positioner can be either single station or dualtwin station in configuration.

Robots should have the number of axes necessary to permit the proper range of motion. Applications from the industry with QuellTech laser measurement technology. The choice of one over the other will come down to the type of item being assembled.

While you may be familiar with how important using proper torch angles are in welding robot programming adds the variable of creating the motion most efficiently and quickly. From arc welding to spot welding new and used welding robots are typically used in welding processes where the weld required is repetitive and quality and speed are crucial. The robot arm should be able to approach the work from multiple angles.

A high-heat torch at the end of the arm melts metal to enable the welding process. The two are articulating robots and rectilinear robots. The training of a robot operator can literally take less than an hour.

Spherical robotic arms can be used for gas welding arc welding spot welding die casting fettling machines and handling machine tools. How Does a Welding Robot Work. These components include those actively taking part in the welding as well as accessories and safety features to ensure the smooth operation of the cell.

This type of robotic arm features two parallel rotary joints which provide compliance in a plane. An arc welding robot uses a process which applies intense heat to metal at a joint causing the metal to melt and intermix. However robots may necessitate regular recalibration or reprogramming.

To use a robotic welding unit programs are inputted via the teach pendant and saved to the controller telling the robot what to do. The production rate required must include the robots speed in performing all the welds on the part plus its air movements. Basics of robotic arc welding.

Robot welding is the use of mechanized programmable tools robots which completely automate a welding process by both performing the weld and handling the part. The result is a strong cohesive bond thats often as strong as the material itself. RobotWorx offers both new and used arc welding and pulsed arc welding robot application options.

Welding is a process where two materials are fused together through heating intermixing and then cooling the materials andor a filler to form a strong join. Find more information here. The welding equipment delivering the energy from the welding power source to the workpiece and the robot providing relative positioning of the heat source and the workpiece.

A basic robotic arc welding system is formed by two subsystems. Generally robot welding takes place within a robotic welding cell and features two primary components. Ad Quelltech Laser Sensor Technology.

The bond however is only as strong as the joining material. Are two popular types of industrial welding robots. Large assemblies that require longer weld cycles are often better.

The robot controller requires welding software that provides the means to communicate to the welding power supply and interpret the need for motion changes to optimize the welding process. Certified human operators still need to remain close to the robots.

Robotic Welding Is It Worth It Pwp Industrial

State Of The Art Of Robotic Welding Metal Working World Magazine

What Is Included In Robotic Welding Systems

Robotic Welding Vs Manual Welding Mac Metal

Robotic Welding Process How Robotic Welding Works

The Simple Way To Flawless Robot Welding Robodk Blog

The Simple Way To Flawless Robot Welding Robodk Blog

Robot Welding Abb Robotics Industries Abb Robotics

Should You Use Mig Or Tig Robotic Welding In Your Application

0 comments:

Post a Comment