Minimize the amount of heat put into the weld. It could also help you weld the entire seam continuously.

Stainless Steel Mig Welding Tips Tricks

Warping of the base plate is caused by heat from the welding arc.

How to keep stainless steel from warping during welding. This will serve as a cooling mechanism or heat sink absorbing the heat while preventing any burn through. Intermittent rather than continuous welds help as does minimizing the amount of filler metal used. Does welded stainless steel rust.

Another alternative is to surround the area youre welding with an Anti-Heat Compound that will block the heat from spreading to the rest of the panel and potentially reduce warping in the panel. Stainless steel one of the most used metals has higher incidences of warping due to its higher coefficient of expansion and low conductivity. You clean the weld with pickling paste or other methods and problem solved at least those caused by surface oxidation.

Weld shrinkage plagues experienced and amateur welders alike. Just remember you need to restrain that metal close to the weld with something much more rigid and anything you can use to absorb the heat will help as well. Carl claims it is 60 as effective as copper for directing the heat that is created from welding.

When butt welding chamfer both sides of the join but keep the included angle less than 60 and make the gap between the sheets as. When you remove the clamps the metal may still distort to a certain extent. How to Prevent Warping When Welding - Kevin Caron - YouTube.

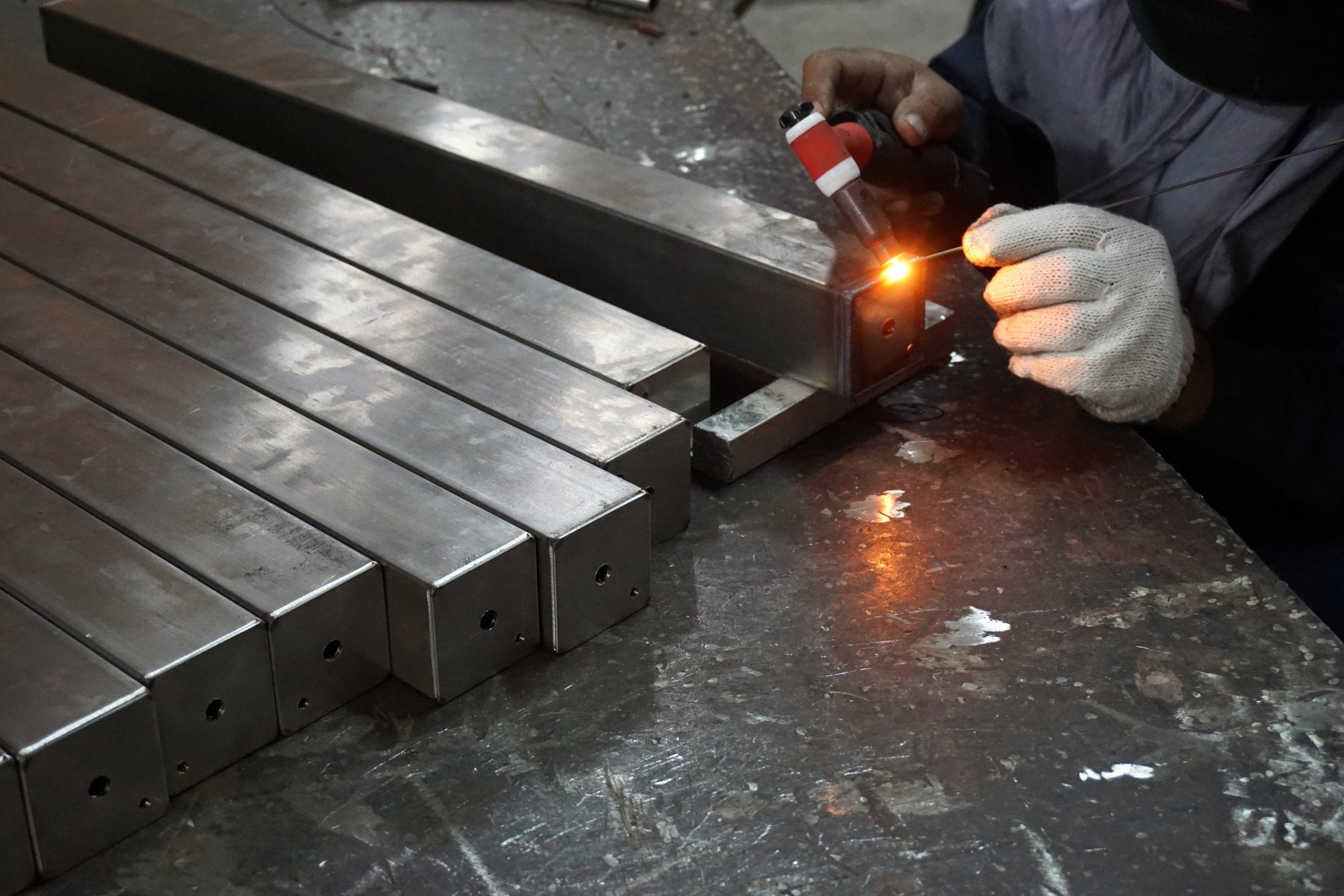

So as to reduce the thermal influence of the parts when welding stainless steel parts try to use gas protection welding as much as you can. One way to prevent warping when welding stainless-steel is to clamp a piece of brass or copper behind the seam of the weld. There are a few things you can do to minimize distortion when tig welding stainless and the main one is to get the puddle established as quickly as possible and get moving.

It could also help you weld the entire seam continuously. This is especially helpful if youre welding in an area that is very critical and could lead to oil canning. How to Prevent Warping When Welding - Kevin Caron.

After i FINALLY got it welded up i left the clamps and holds on and lt it cool over night. During stress relieving some minor relative movements will take place. One way to prevent warping when welding stainless-steel is to clamp a piece of brass or copper behind the seam of the weld.

Shrinkage causes distortion of the weldment. Dont taper amperage any slower than needed. Since stainless steel has a low thermal conductivity heat builds up quickly so tig welding stainless.

Weld warping corrective techniques The primary way of eliminating warping is through hammering. This will serve as a cooling mechanism or heat sink absorbing the heat while preventing any burn through. The higher the heat input the slower the cooling rate.

Bolting the stainless steel to an aluminium block helps to suck the heat away from the weld. I tacked the peices together and using a ton of clamps welded an inch here then an inch over there. Keeping the heat on using some rose buds and a few flunkies.

Being bolted to the aluminium also serves to keep the stainless. Our copper weld backers help to keep a welds from blowing through the metal and also act as a heat sink. Another method uses mechanical peening of the weld either by hammering or by shot peening equipment.

Using clamps strongbacks and other methods of holding parts in place can keep the metal from moving during the welding process and holding it in the proper position as the metal cools and stresses are acting on the material. What i ended up doing was i got the aluminum hot an kept it under constant heat. Upon cooling the residual stresses will stay significantly reduced.

Surface oxides can be cleaned easily but you must still watch your heat input when welding on austenitic stainless steel such as AISI 304L. This is done sometimes on tool steels immediately after shielded metal arc welding and before cool down. Clamping a solid piece of flat stock on both sides close to your weld will also help things stay straighter.

Distortion results from the expansion and contraction of the weld metal and adjacent base metal during the welding process.

Common Methods Of Welding Stainless Steel Millenium Alloys

Stainless Steel Passivization To Stop Rust After Weld 0 Youtube

Stainless Steel Welding Tips Improving Quality In Tig Welding Red D Arc Welderentals

Common Methods Of Welding Stainless Steel Millenium Alloys

Stainless Steel Welding Tips Metal Shop Fantasy Camp

4 Best Ways For Stainless Steel Welding A Quick Guide Cruxweld

How To Fix Stainless Steel Welding Deformation Analysis Solutions Machinemfg

How To Weld Stainless Steel 7 Best Practices Sensible Digs

How To Fix Stainless Steel Welding Deformation Analysis Solutions Machinemfg

0 comments:

Post a Comment