The AISI 1050 steel depending upon carbon equivalency may benefit from a PWHT application. For ASTM A709 Grade HPS 70W and ASTM A852 the maximum preheat and interpass temperatures shall not exceed 400F 200C for thicknesses up to 1-12 in 40 mm inclusive and 450F 230C for.

Https Www Kobelco Co Jp English Welding Files Kwt2001 01 Pdf

Maintain low interpass temperature 150C max.

Interpass temperature for carbon steel welding. Therefore the interpass temperature must be restricted to ensure the required mechanical properties. But weld metal cracks were observed in the non-preheat condition while they were stopped at 50Ž preheating. And in most cases preheating to 300F will costs you more than double that of preheating to 150F.

For carbon steels the maximum interpass temperature is around 600 deg F. Its hard to keep the 32 F 50 F and 70 F around even in my neck of the woods. Large weave high welding current slow travel speed Austenitic stainless steels.

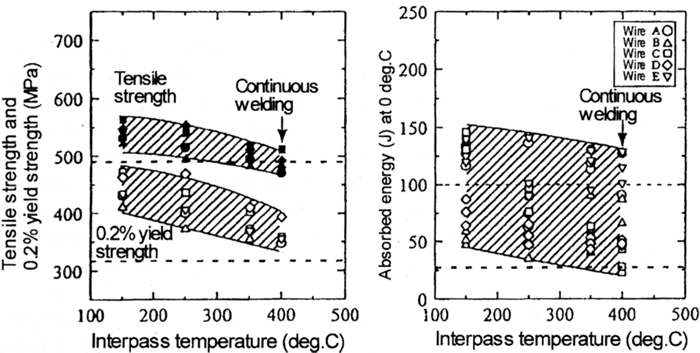

High values of interpass temperature tend to reduce the weld metal strength. The maximum interpass temperature during welding should not exceed 400 degrees F for the welded joint. American Welding Society Position Statement on the Northridge Earthquake recommends that interpass temperature not exceed 550 F when notch toughness is a requirement.

There are other times when a designer may want to limit the maximum interpass temperature. As you go to higher alloy steels or air hardening steels the maximum interpass temperature may be less than 600 deg F to avoid adding too much heat into the surrounding base material recognizing that you want to increase arc time for weld production. Typical CTOD test results of DW-55L weld metals in the conditions mentioned in the footnotes Welding position Flat Vertical Horizontal CTOD at 10C δc mm 064 059 034 168 205 155 050 061.

For example for carbon steel welding the B311 Code requires preheating to a temperature of 175_F 80C when the carbon content exceeds 030 percent and the thickness of the joint exceeds 1 in. B313 recommends preheating to 175F 80C when the base metal specified strength exceeds 71 ksi or the wall thickness is equal to or greater than 1 in 25 mm. Pcm is suitable for the steels except steel.

The best thing to do is to determine the adequate preheat temperature for the base metal you are welding. As shown in Fig. Avoid high heat input techniques ie.

However when interpass temperatures exceed approximately 500F 260C this trend may be reversed. Ad Find China Manufacturers Of Welding Wire. Interpass temperature refers to the temperature of the material in the weld area immediately before the second and each subsequent pass of a multiple pass weld.

Of Interpass Temperature Key Concepts in Welding Engineering by R. When the base metal temperature is below 32F 0C the base metal shall be preheated to a minimum of 70F 20C and the minimum interpass temperature shall be maintained during welding. Case of carbon manganese and ferritic alloy steel.

Ad Find China Manufacturers Of Welding Wire. However it is not recommended that the A514 steel be used in the PWHT condition. Additionally higher interpass temperatures will generally pro-vide a finer grain structure and improved Charpy V notch toughness transition temperatures.

Allow the release of weld metal hydrogen. Scott Funderburk Interpass temperature refers to the temperature of the material in the weld area immediately before the second and each subsequent pass of a multiple pass weld. Special Considerations for Duplex Stainless Steels.

400- 500 200- 250 approx Above ½ inch 25 mm thickness. A maximum interpass temperature of 300F 150C is recommended. The figure suggests that a maximum interpass temperature should be 250C to.

500- 600 250- 300 approx The above preheat temperature is based on the recommendation given in Welding handbooks such as ASM and AWS. As shown in Table 2 the DW-55L weld metal possesses sufficient CTOD values at minus 10C. In practice the minimum specified interpass temperature is often equal to the minimum specified preheat.

This way you will make sure you are not heating excessively and incurring unnecessary costs. Up to ½ inch 12 mm thickness. 1 CEIIW is a preferable index for carbon steels and carbon manganese steels but absolutely unacceptable for low-carbon low-alloy steels.

A typical structural steel welder or weld inspector should keep crayons rated at 150 F 225 F 300 F 400 F and 450 F around at all times. High values of interpass temperature tend to reduce the weld metal strength. INTERPASS TEMPERATURE When welding alloys which do not contain ferrite a lower interpass temperature is preferred which lowers thermal stresses.

The AISI 4140 steel is recommended to preheat. STEEL PREHEATING CHART Pre-Heating will eliminate crack formation reduce distortion and prevent shrinkage stresses Metal Metal C Recommended Group Designation Preheat 0F Plain Plain carbon steel Below20 Up to 200 Carbon Plain carbon steel 20-30 200-300 Steel Plain carbon steel 30-45 300-500 Plain carbon steel 45-80 500-800.

What Is The Major Difference Between Gtaw And Gmaw Gmaw Gtaw Welding Jobs

Recommended Preheat And Interpass Temperatures For Common Csef Steels 32 Download Table

Https Www Kobelco Co Jp English Welding Files Kwt2001 01 Pdf

The Comparison Of T 8 5 Under Interpass Temperature Download Scientific Diagram

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Calculation Of Preheating Temperature Tp And Interpass Temperature Ti Download Scientific Diagram

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Welding Interpass Temperature Control Oil Gas Industry Technology Updates

What Is Mcaw Welding Welding Welding Jobs Gmaw

0 comments:

Post a Comment