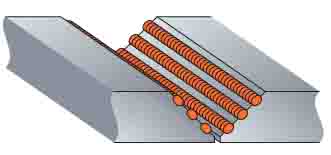

Braze welding is a common method for joining cast iron parts due to the minimal impact on the base metal itself. Using the methods discussed above weld the studs in place and cover the entire surface of the break with weld deposit.

Cast Iron Welding Basic Procedures Weld Guru

The most common method of cast iron welding is stick or arc welding.

Method of welding cast iron on ship. You would remove the cast iron part put it in an oven to slowly heat it weld it with cheap nickel-based welding rods put it back in the oven for a second time to slowly cool it down then reassemble. By choosing the right filler material and welding method you can weld cast iron along with other welding processes such as MIG TIG welding. The tensile strength of the joints was determined using a conventional tensile test machine.

When welding cast-iron by the metallic arc process with cast-iron electrodes it is usually necessary to preheat the casting. Welding Marine Engineering History. 81 High alloy cast iron.

Please refer to Surface and joint preparation. However that would usually lead to more. 1- To clean grease or other contaminants from cast iron heat the pieces uniformely to between 700 1000F 370 540C until all volatizing stops about one hour.

Welding should be executed by a qualified and experienced welder and adequate safety measures should always be adhered to. A common method that is used for joining cast iron parts together is brazing. The filler adheres to the cast iron surface and since it has a lower melting point than the base metal it doesnt dilute with it.

Ideally heat up the entire part. A welding rod provides the filler that adheres to the cast iron surface. 95 20711 Cold repair on cast iron.

View more Cast Iron Welding How-To articles. Method of joining metals have been known for thousand of years but for most of this period the only form of welding was forge welding by a blacksmith. There are several ideal methods that you could use to repair cast iron that does not require welding.

PRACTICAL TIPS FOR WELDING CAST IRON. Such techniques include brazing the use of epoxy putty and the use of cold metal stitching. Brazing isnt really welding as it doesnt fuse the metal as a weld does.

Oxy-acetylene welding is another option frequently used to weld cast iron. Its advantage is that it has minimum impact on the base metal. If the part is too big and you cant heat the whole thing up then heat the largest area possible.

Many MMA consumables for cast iron welding have special coatings to minimise arc penetration. Then fix any cracks or rips in the surface by using a small piece of iron as a repair. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

20703 White cast iron. Use the appropriate rod type. 87 20710 Braze welding of cast iron.

To weld cast iron start by preheating the section youll be working to a temperature between 500 to 1200 degrees F so that its stable enough to work with. Also dont let the iron get hotter than 1400 F bright red. 83 20708 Preparation of the work piece.

Manual metal arc MMA welding known as SMAW in the USA is by far the most popular method for welding cast irons. Because of the lower melting point of the filler compared to the cast iron the filler does not dilute with the cast iron but adheres to. Once a good weld deposit is made the two sides of the crack can be welded together.

It is recommended that you use ideal methods when repairing your cast iron pieces. Number of new welding principles emerged at the end of 19th Century sufficient electrical current could then be generated for Electric Arc Welding and Resistance Welding. Welding that hot bad.

Prepare the job with a groove in U. Moreover the hardness across the. Welding Cast-Iron with Preheating.

The best all-round method for Welding Cast Iron is arc welding. 80 20705 Ductile cast iron. Welding Handbook Welding and Related Processes for Repair and Maintenance Onboard 10th edition Notice.

All welding is carried out on the welders own risk and account. Take your time heating it up make sure its slow and even. Thats the critical temperature range of iron.

Ensures a little preheat at room temperature. In general the best results are obtained when welding with low current and the lowest practical heat inputs. 84 20709 Arc welding of cast iron.

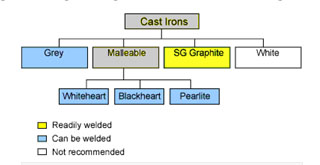

80 20704 Malleable cast iron. 82 Identification of cast iron. In this paper ductile cast ironaustenitic stainless steel ductile cast ironpure Armco iron and ductile cast ironlow carbon steel interlayers were welded using the friction welding method.

Well historically the most reliable method has been to apply a special heating and cooling approach. View Cast Iron Stick Electrodes. Preheating welding produces very tight and strong welds.

Stick Welding Cast Iron Repair Using 7018 Welding Rods Youtube

Cast Iron Welding Basic Procedures Weld Guru

The Welding Factors Of A Cast Iron Fully Depend On The Material Type Complexity Thickness Casting Complexity And Need Welding Cast Iron Tig Welding It Cast

How To Weld Cast Iron Metal Casting Blog

Post 924 12859518065975 Jpg 1200 921 Blacksmith Tools Forging Tools Blacksmithing

An Essential Guide About Repair Welding Electrodes Tig Welding Process Welding Process Welding Electrodes

Cast Iron Welding Procedure Step By Step Guide Cruxweld

Metal Spraying Also Is Very Important For The Overall Infrastructure So That All The Walkways And Related Areas Are Safe For People To Walk In Therefore This

0 comments:

Post a Comment