Argon 2nd choiceargon 30 helium standard austenitics 304 316 etc--1st choiceargon 2nd choiceargon 30 helium 3rd choiceargon 2 hydrogen Fully austenitics 254 SMO etc--1st choiceArgon 2nd choiceArgon 2N2 3rd choiceAr 30 He2 N2 Duplex 2205 2507--1st choiceAr 2nd. You can either choose from the following combinations.

Stainless Steel Mig Welding Electrode Wire And Gas Choices Gowelding Org

C5 or 5 Carbon Dioxide and 95 Argon.

Shielding gas for mig welding 316 stainless steel. Somewhere on the internet I saw a professional study on the effects of CO2 on welding stainless. Most often used when MIG welding stainless steel with solid welding wire. There are also Argon with 25 Oxygen mixes but the most common is either the 25-3 Co2 or the ArHeCo2 mixes.

The tri-mix shielding gas that has been brought up is the most suitable choice for MIG welding stainless steel. 75 Argon 25 Carbon Dioxide 7525 90 Argon 10 Carbon Dioxide 9010 95 Argon 5 Oxygen 955 And many other mixtures. In 321 310 316 347 304 410 and similar stainless steels can be successfully made.

90 Helium plus 75 Argon plus 25 Carbon dioxide. Ferritic and martensitic--1st choice. C25 or 25 Carbon Dioxide and 95 Argon.

The mixture provides benefits including an increased amperage for quicker welds without the undesired more extreme heat. Argon or argonhelium mixtures can be used for welding all grades. C10 or 10 Carbon Dioxide and 95 Argon.

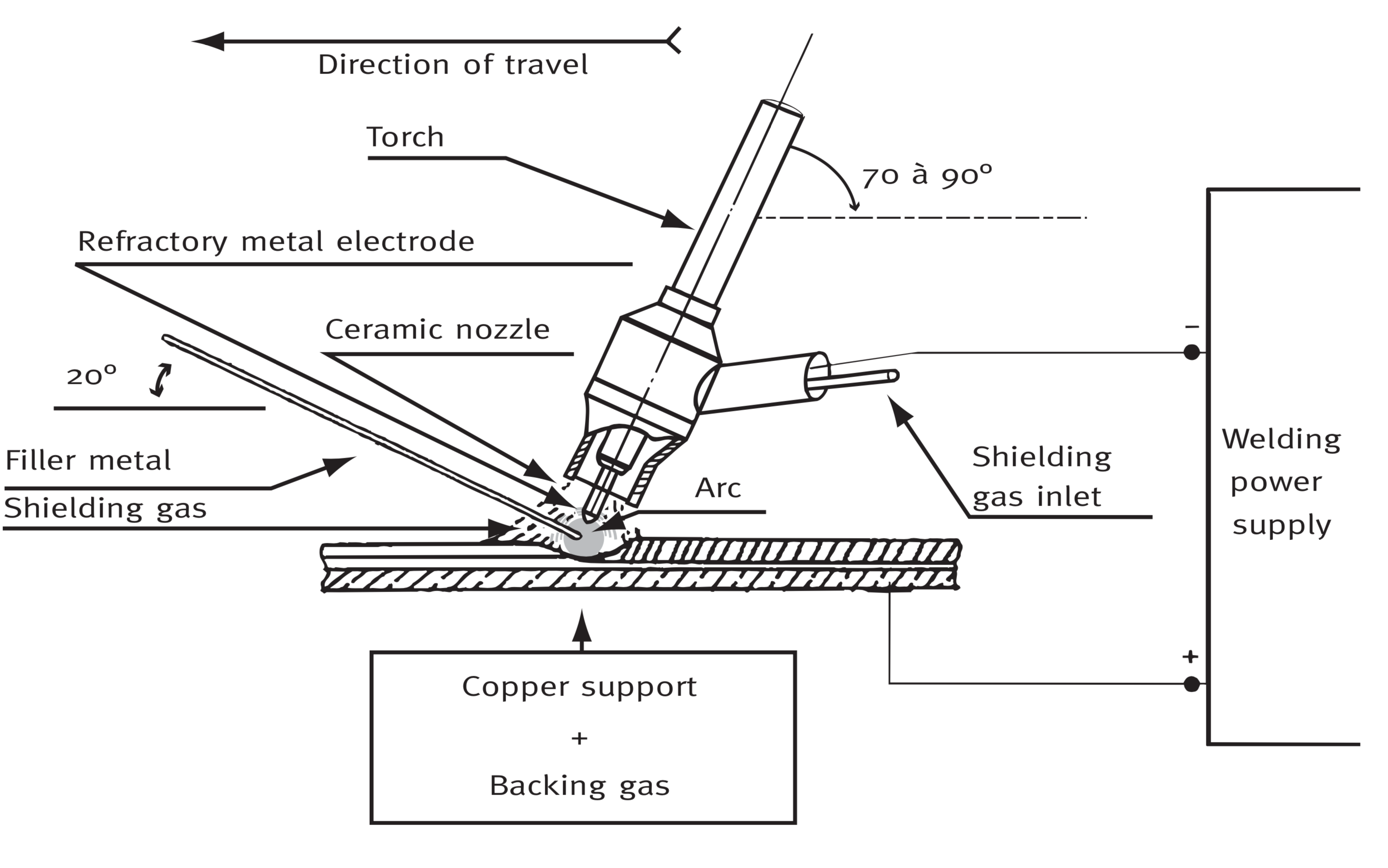

Gas Shielding is Critical for Stainless Steel Welds Some stainless steel welding codes require gas shielding on the back side. The addition of helium to argon increases the available energy to the weld pool making it more fluid. A real advantage because its a cheap shielding gas to buy.

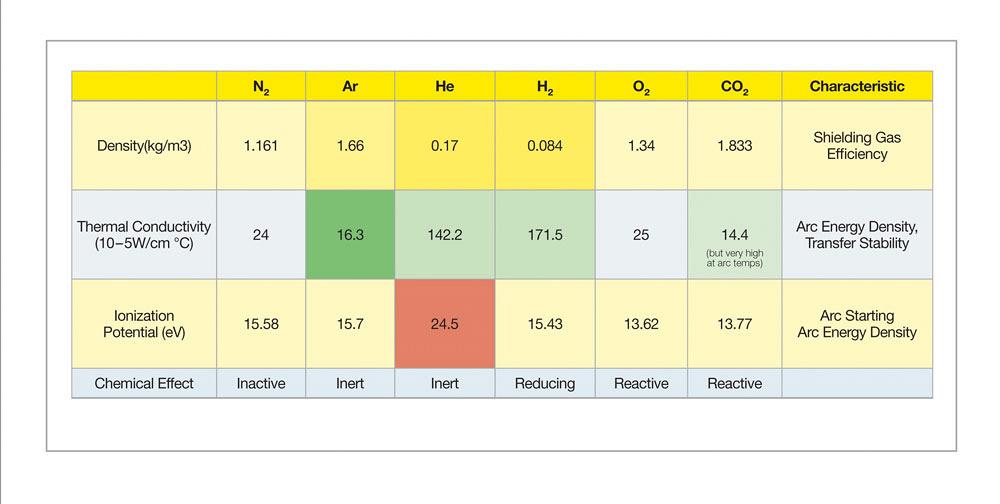

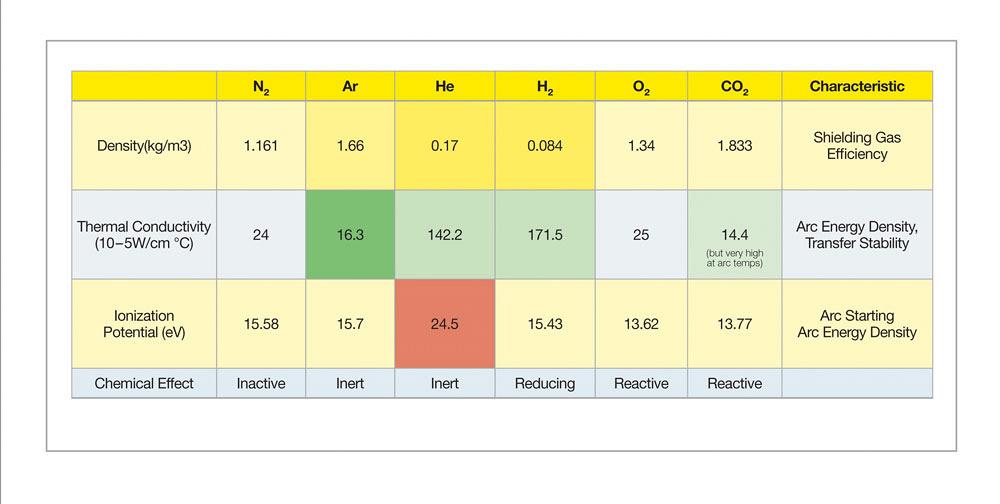

Therefore the recommended shielding gas to use for short circuit stainless steel MIG welding is a tri-mix shielding gas such as 90He75Ar25CO2. Each of these gases has its pros and cons. Shielding gasses for MIG.

C2 or 2 Carbon Dioxide and 98 Argon. Ad Find China Manufacturers Of Mig Welding. Second Choosing a Shielding Gas An important factor or the most important when choosing the correct shielding gas mix is that stainless steel has a sluggish weld.

Argon plus carbon dioxide gas is the best gas for stainless steel welding. Butt lap and single fillet welds in material ranging from 060-in. For example you can weld mild steel with any of the following shielding gases.

Previously an ArgonOxygen mix was widely used but this doesnt give as smooth a finish as the ArgonCO2. Tri-Mix Gas 90 Helium 75 Argon and 25Carbon dioxide. Shielding gas protection Shielding gases for MIGGMAW welding.

In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide. Right around 5 corrosion picked up. 100 Carbon Dioxide is often the shielding gas used with these stainless steel wires.

The best gas for MIG welding stainless is 975 Argon 25 CO2. Welding of stainless steel is typically done with C2 or 2 Carbon Dioxide and 98 Argon. Short-circuiting transfer welds on stainless steel made with a shielding gas of 90 He 7-12 A 2-12 CO2 show good corrosion resistance and coalescence.

There are many types of shielding gas that can be purchased such as. Therefore you do not want to use a completely inert shielding gas such as 100 helium or 100 argon for stainless steel MIG welding. Helium He can be added to increase penetration and fluidity of the weld pool.

Shielding gases for TIG welding. When you compare it to an Argon Carbon Dioxide gas mix. Food service codes for example do not tolerate a bunch of germ trapping crevices in the weld area.

Gases for all types of stainless steels The right gas mixtures for TIG and plasma welding VARIGON He30 This argon and helium gas mixture is suitable for TIG welding all grades of stainless steel. Basic shielding gas choices for Stainless are. This can either straight Co2 and Argon or a Argon Helium Co2 mix.

Shielding Gasses for Stainless Steel MIG Welding. Keep in mind that there is no perfect gas to be used when MIG welding. This data seems to line up with Ed Craigs suggestion of 2-4 for thin stainless and seems to match Yorkiepaps observationexperience.

That doesnt mean that for what you want to. This in turn increases the penetration. The amount of carbon dioxide can be from 2 up to 25 of the.

Regardless of what anyone else says you shouldnt use a mix of more than 25-3 Co2 for Mig welding Stainless Steel. Shielding gas protects the melting metals from being exposed to outside gases by using a steady stream of a different type of gas. Choosing the right shielding gas matters.

Mostly the 95 Argon plus 2 Carbon dioxide gas is used. Ad Find China Manufacturers Of Mig Welding. Likewise people ask do you need gas to weld stainless steel.

And definitely cheaper than your Helium based Tri Mix. MIG Welding Gas for Stainless Steel Welding. Carbon Steel MIG Weld done with C25 Gas.

The basic gas for MIGMAG welding is argon Ar. 316L filler wire is good for 316L and 316 base metals while 309L filler metal is used when joining mild steel or low alloy steel to stainless steels.

The Welding Of Stainless Steels Safe Food Factory

How To Weld Stainless Steel Mig Unugtp

Stainless Steel Mig Welding Tips Mig Monday Youtube

Shielding Stainless Steel Correctly For Welding

Hot Selling Good Quality 1 0mm 316 Stainless Steel Mig Welding Wire Buy Ss Welding Wire 0 8 Mig Wire Mig Welding With Flux Core Wire Product On Alibaba Com

Stainless Steel Fcaw Without Gas Youtube

New Regulated Metal Deposition Rmd Mig Welding Process Improves Stainless Steel Pipe Fabrication

Stainless Steel Mig Welding Electrode Wire And Gas Choices Gowelding Org

0 comments:

Post a Comment