If proper welding techniques and procedures are followed high-quality welds can be produced with conventional arc welding processes. Other combinations of parameters can also be selected to produce the same weld appearance.

Cv Kew Tungsten Innert Gas Tig Atau Gtaw

Welding for the same heat or less heat input for the same speed.

The procedure for welding all types of stainless steel with gtaw is the same. The significant differ-ence is that the arc plasma is constricted by a nozzle to produce a high-energy plasma stream in which temperatures between 10 000 and 20 000C are attained. The welding methods presented here are. The utmost importance when determining a suitable weld process or procedure.

The electrode coating provides shielding. What tungsten do I use for mild steel. This WPS will be presented to the Canadian Welding Bureau CWB along with the related WPDS for approval.

However the microstructural change that occurs during welding and at weld joint is still a major challenge today as it affects both the. For any of these. Wind velocities shall not exceed 5 mph in the weld area.

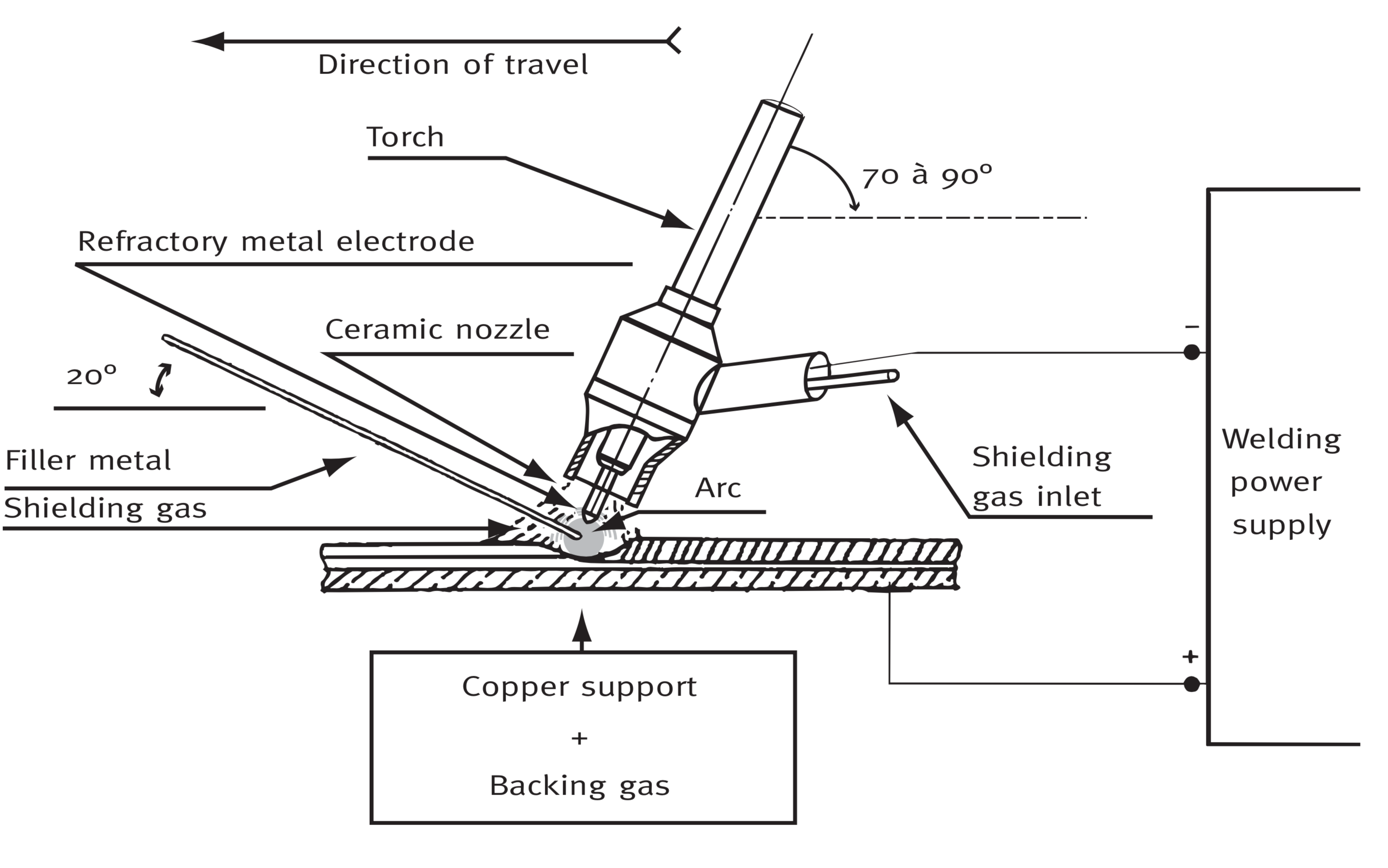

Gas Tungsten Arc Welding GTAW or Tungsten Inert Gas Arc Welding TIG here called GTAW. Joining stainless steel to carbon steel. Shielded Metal-Arc Welding SMAW Wind velocities shall not exceed 10 mph in the weld area.

SMAW - S hielded M etal A rc W elding or Stick Electrode. However please be aware of the proper techniques for welding these types of alloys and the differences compared to the more common. An internal gas purge shall be provided for the root pass and the second layer of autogenous and stainless steel welds.

Gas Metal Arc Welding GMAW This process relies on a non-consumable tungsten electrode to carry the electric current to the workpiece. Welding Procedure The welding shall be done Semi-automatically using the Gas Metal Arc Welding GMAW process Note. For each test the parameters are listed.

Gas Tungsten-Arc Welding GTAW Advertisment. SMAW is an electric arc welding process in which heat for welding is generated by an electric arc between a covered metal electrode and the base metal. OK 6125 is a basic coated stainless-steel electrode of the 308H type.

Gas Tungsten Arc Welding GTAW. The welding procedure are used respec-tively. Most stainless steels are considered to have good weldability and may be welded by several welding processes including the arc welding processes resistance welding electron and laser beam welding friction welding and brazing.

2 Thoriated Tungsten Electrodes Red Tipped Containing 17 to 22 thorium oxide this radioactive tungsten electrode works well with mild steel stainless steel and other non-corroding metals. GTAW technique is one of the major processes for joining austenitic stainless steels ASS and ferritic stainless steel FSS fabrication. Comparison of Welding Characteristics of Type 304 Stainless Steel with Carbon Steel Carbon Steel Type 304 Remarks Melting Point 2800 2550-2650 Type 304 requires less heat to produce fusion which means faster ºF Approx.

Plasma welding is similar to Gas Tungsten Arc Welding GTAW. Welding processes generally employ a transferred arc configuration where the. The three most common stainless welding processes are.

The Welding Of Stainless Steels Safe Food Factory

Tig Welding Or Gas Tungsten Arc Welding Gtaw Process

What Is The Major Difference Between Gtaw And Gmaw Gmaw Gtaw Welding Jobs

Guidelines For Gas Tungsten Arc Welding Gtaw Miller

Gas Tungsten Arc Welding Wikiwand

The Welding Of Stainless Steels Safe Food Factory

Effect Of Polarity On Gtaw Weld Configuration When Using Direct Download Scientific Diagram

What Is Gtaw In Welding Gtaw Welding Gas Tungsten Arc Welding

What Is Gtaw And Smaw Welding Smaw Welding Gtaw Welding

0 comments:

Post a Comment