Although there are around five types of arc welding processes that are presently utilized there are two welding methods that can be best used to weld copper. Copper alloys can be welded with most of the conventional welding processes although of the arc welding processes gas shielded arc methods are the most common.

Copper Pipe Joining Methods Miracle

The best way to weld steel into copper is to use soldering technology because the melting point of the required additive metal and the copper-nickel alloy are so different.

Welding copper method. These are gas tungsten arc welding GTAW and gas metal arc welding GMAW. When access is only possible from the steel side the joint is prepared to leave the copper- nickel cladding protruding so that it can be welded the same as for the solid alloy. Automatic welding can also be used for large structures.

1 Gas Tungsten Arc Welding GTAW. 841 Ventilation and Shielding gas. The high thermal conductivity of copper usually the main difficulty in its welding.

The methods of welding red copper include gas welding manual carbon arc welding manual arc welding and manual argon arc welding. Gas welding of red copper. This invention relates to a method of welding duplex metal members more particularly to welding members comprising a ferrous metal base such for example as steel or an iron alloy 9 and to which base metal is bonded a copper or copper alloy but the method is not limited to this material but may be used to weld duplex metals of different combinations of metals and it is an objec.

FCAW FCAW-S Continuous consumable electrode filled with flux Industry construction Gas Metal Arc Welding. Although about five arc welding processes are used today two welding methods can best be used to weld copper. There are various welding methods of copper and different welding methods of copper products are also differentGenerally used methods are gas welding manual carbon arc welding manual arc welding and manual argon arc welding and other four methods large structures can also be used automatic welding.

9 Whats the Weldability of Copper to Steel or Stainless Steel. Tungsten gas arc welding GTAW. The cladding is prepared for welding cutting into the steel weld and allowing for at least two runs.

91 Is TIG the Best Choice. Another method is to overlay the copper with a nickel-base electrode. And welding and connecting the end to be welded of the copper material and the end to be welded of the steel material by a heating part of a heat supply device under the protection of a shielding gas wherein the top end of the heating part is shifted towards the copper material and the end to be welded of the copper.

When making the overlay welds on thick copper the copper should be preheated to 540C 1000F. The overlay or buttered surface of the copper part should be smoothed to provide a uniform joint preparation. Due to this reason a great amount of heat is required to be produced at the job so as to make good weld.

Manual Metal Arc Welding MMAW This method is mainly used to perform repair or maintenance welding on copper and copper alloys. Butt connecting or sleeve connecting an end to be welded of a copper material with an end to be welded of a steel material. 7 How to TIG Weld a Copper Pipe.

These are the Gas Tungsten Arc Welding GTAW and the Gas Metal Arc Welding GMAW. Ad Find China Manufacturers Of Welding Wire. The first being of the 65 nickel -copper alloy referred to earlier followed by the 70-30 Cu-Ni.

Bare Metal Arc Welding 113 BMAW Consumable electrode no flux or shielding gas Historical Carbon Arc Welding 181 CAW Carbon electrode historical Copper repair limited Flux Cored Arc Welding. The filler material recommended for this is method is ECuSn-C electrode. Another recommendation is using Direct Current electrode positive DC with a stringer bead technique.

Preheating. A second overlay or layer is recommended on thicker materials. Ad Find China Manufacturers Of Welding Wire.

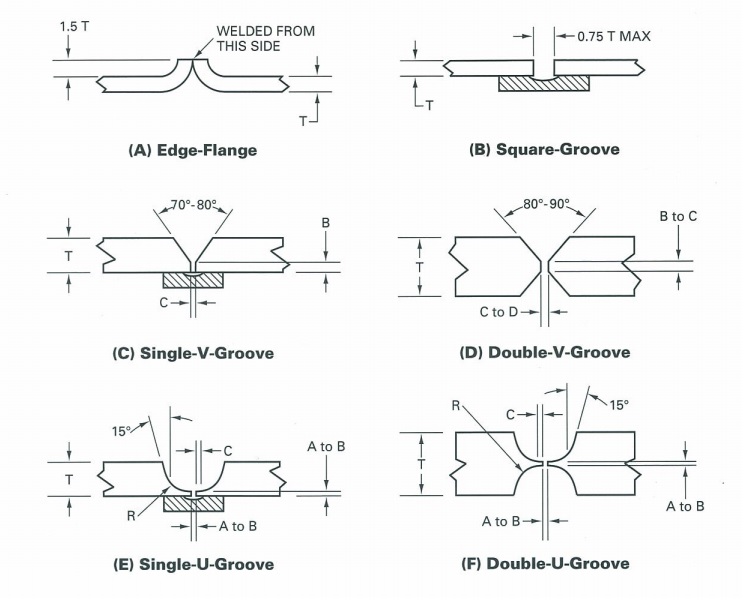

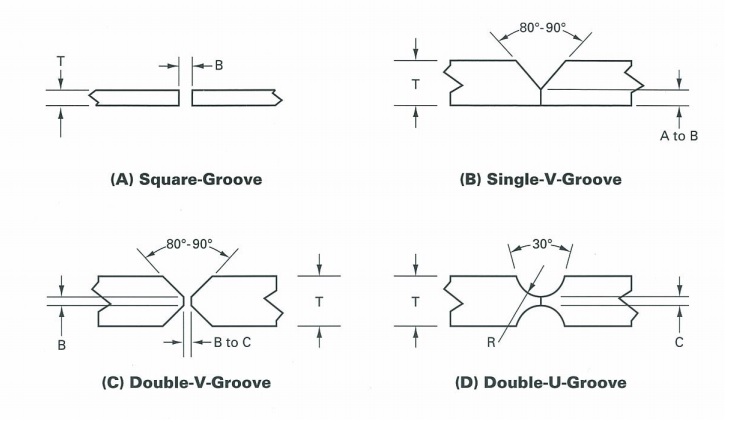

The welding method includes the following steps. Butt joints are most commonly used for welding red copper and lap joints and T-joints are used as little as possible. No matter which welding method you choose you will have to cling to a surface as copper and nickel alloys tend to distort.

1 Gas welding A Gas welding of copper. Such copper can be suitably welded by most of the fusion welding processes.

Guide To Copper Welding Weld Guru

Welding Copper Tips Forster America

Aufhauser Technical Guide Copper Welding Procedures

Aufhauser Technical Guide Copper Welding Procedures

How To Weld Copper Welding Headquarters

Method Statement For Brazing Jointing Of Copper Pipes Method Statement Hq

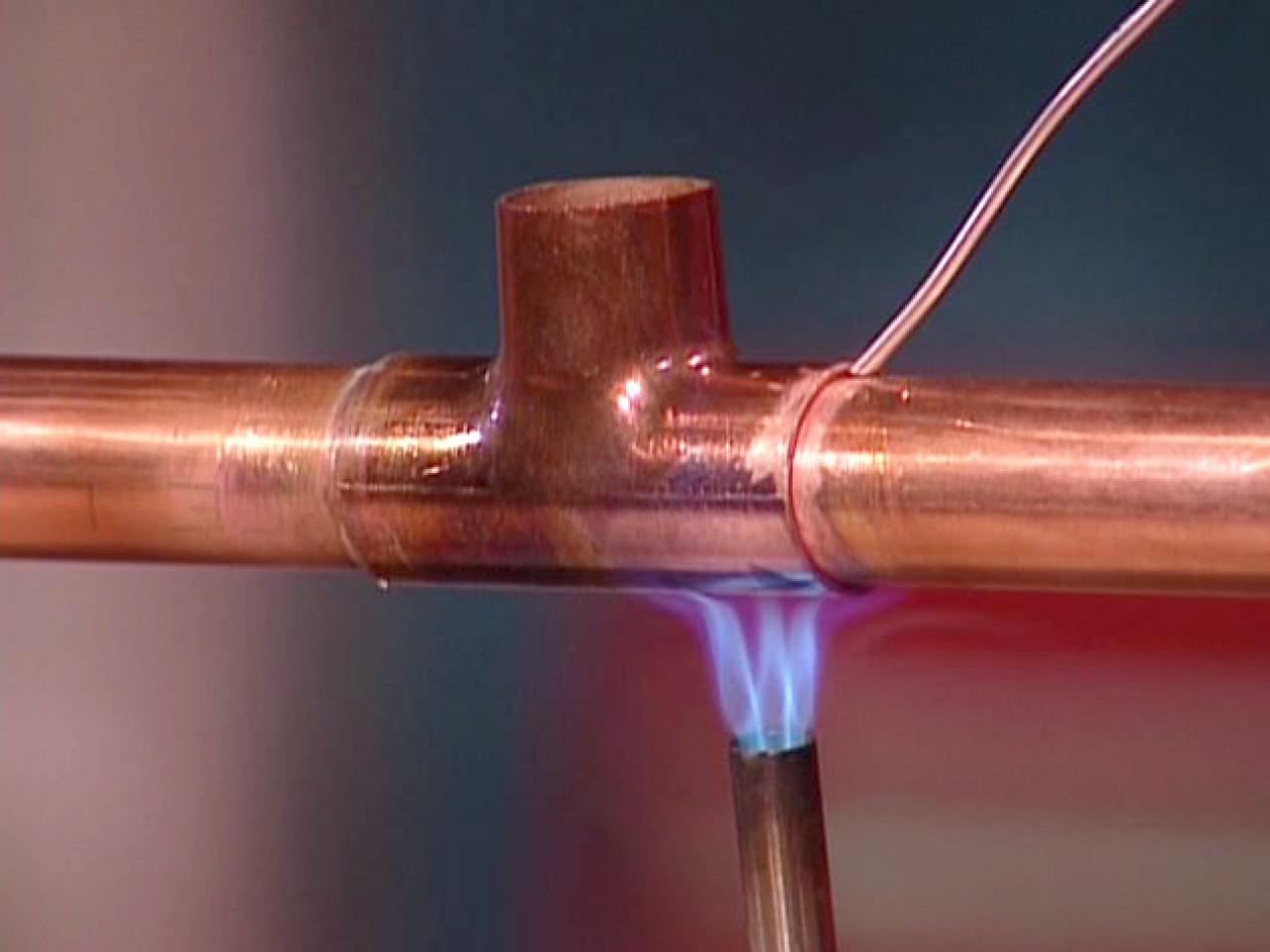

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Use Oxyhydrogen Gas Welding For Copper Tube Welding

Schematic Of The Welding Process Of Copper And Stainless Steel Download Scientific Diagram

0 comments:

Post a Comment