1Metal Point of Metal. From the definition it is clear that melting poin.

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Owing to these overwhelming benefits seam welding is the default choice in welding operations where the strength of the finished weld joint is a paramount factor.

Welding factor meaning. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas. Weldeability meansweldeability of metalsweldeable metalstestings for checking weldeabilityalloying elements and their effects on weldeability. - The change in chemical composition of a welding filler material caused by the admixture of the base material or previously deposited weld material in the deposited weld bead.

Factors affecting on Welding. A power supply creates an electric arc between a consumable or non-consumable electrode and the base material using either direct DC or alternating AC currents. If the welding rod comes with 4-digits then the first two numbers stand for tensile strength.

When helium is used this is known as heliarc welding. In simple weld-ability is the ability of material to be welded or join-ability of material. A filler metal is normally used though some welds known as autogenous welds or fusion welds do not require it.

It is also better for thinner sections since it produces less distortion as a result of lower heat input. AC DC OR DC-. Welding Symbol A graphical representation of a weld.

Welding Rod A form of welding filler metal normally packaged in straight lengths that does not conduct the welding current. This equation assumes that the welding bus is constant. The E entails the arc welding electrode.

Welding operators must also know the correct operating procedures for the equipment. Welding Technique The details of a welding procedure that are controlled by the welder or welding operator. If it has 5-digits then the first three will be for the tensile strength.

It is normally measured by the percentage or base material or previously deposited weld material in the weld bead. As we Know Welding is an art of joining two metals by heating to high temperature almost enough to melting point of the material to be welded. If the strength of weld obtained is equal to the strength of base metal and weld does not contain any defect then it is called a good weld The weld quality is directly related to weld design magnitude of residual stresses strain set up by welding heat layout of welded joint quality of base metal and quality of work preparation and fit ups.

The electric arc heats and melts the two metals together which in turn fuses the two metals together resulting in a stronger bond. What is the X-factor. Following factors will influence the severity of electrical shock.

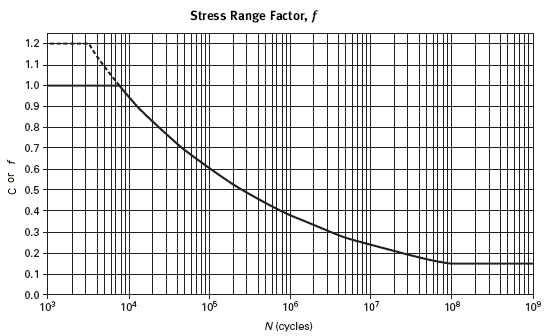

It is important to note that the current flow is not only affected by the resistance of the tools but also by the voltage of the bus as expressed by Ohms Law. C-Factor absolute I max 100 I sec I. This article is one of a series of TWI frequently asked questions FAQs.

The X-factor is a calculation or formula that measures a weldments resistance to temper embrittlement-a brittleness or loss of toughness that occurs when the weldment is held or slowly cooled through a temperature range of approximately 850 to 1100 degrees Fahrenheit. System or transmitted in any form or by any means electronic mechanical photocopying. Required minimum safety factor of weld joint during static loading n s represents a ratio of allowable stress and the yield strength of joint material n S S Y σ Al or n S S Y τ Al.

Arc welding is a type of welding process using an electric arc to create heat to melt and join metals. When you look at a welding rod youll notice that all the numbers are accompanied by the letter E. However stitch welding can save time and money for welding applications where strength requirements can be relaxed.

Gas tungsten arc welding also known as tungsten inert gas welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. Welding is the process of fusing two pieces of metals also called workpiece together. This is accomplished by passing electric current from the welding electrode to the workpiece that creates an electric arc.

Required safety of weld joint is affected by method and quality of weld design shape and machining of the weld surface weld reinforcement weld homogeneity penetrations and so on.

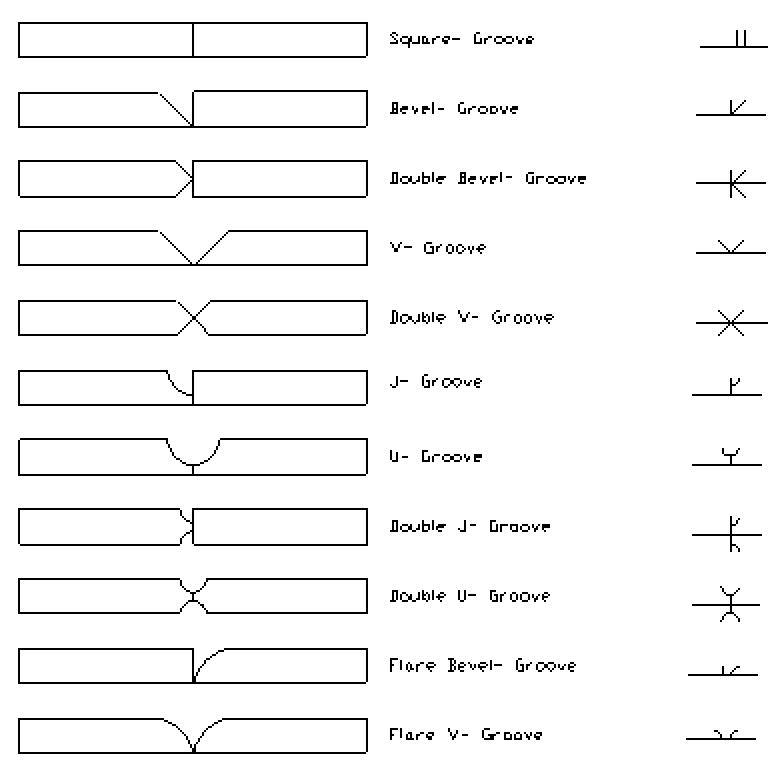

Groove Welding Symbols Interpretation Of Metal Fab Drawings

Weld Joint Reduction Factor For Pressure Vessel And Piping Engineers Edge Www Engineersedge Com

All Kinds Of Magnetic Welding Holder Magnets Welding Holder

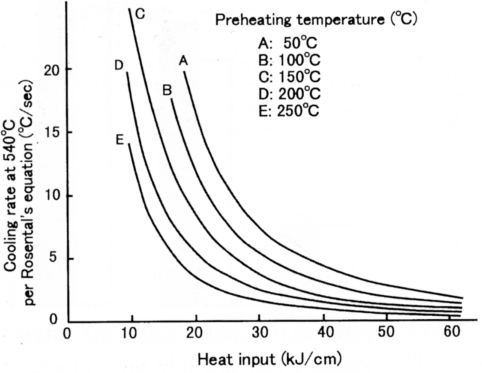

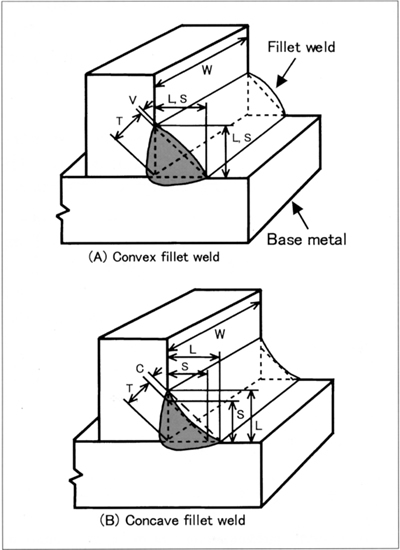

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

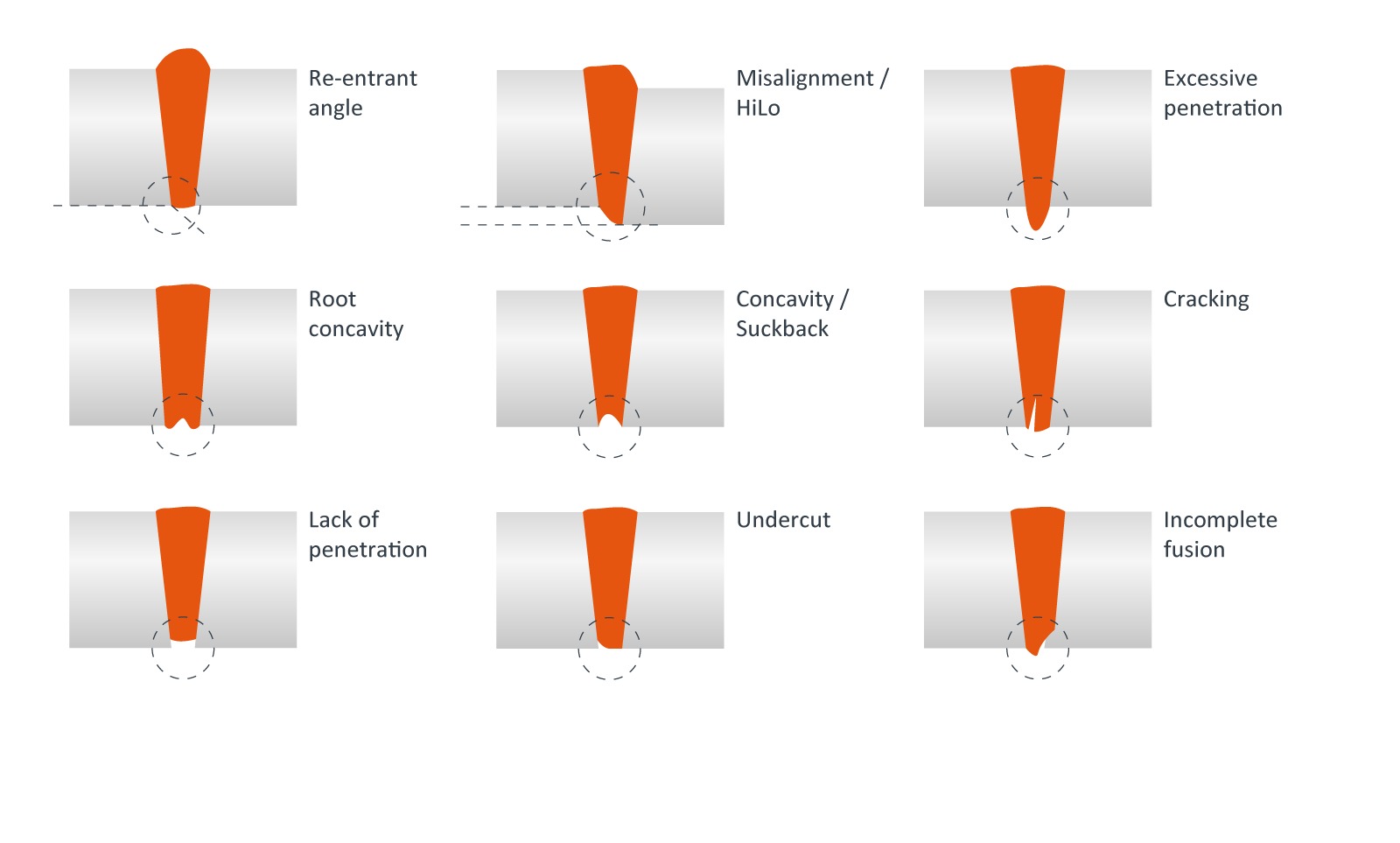

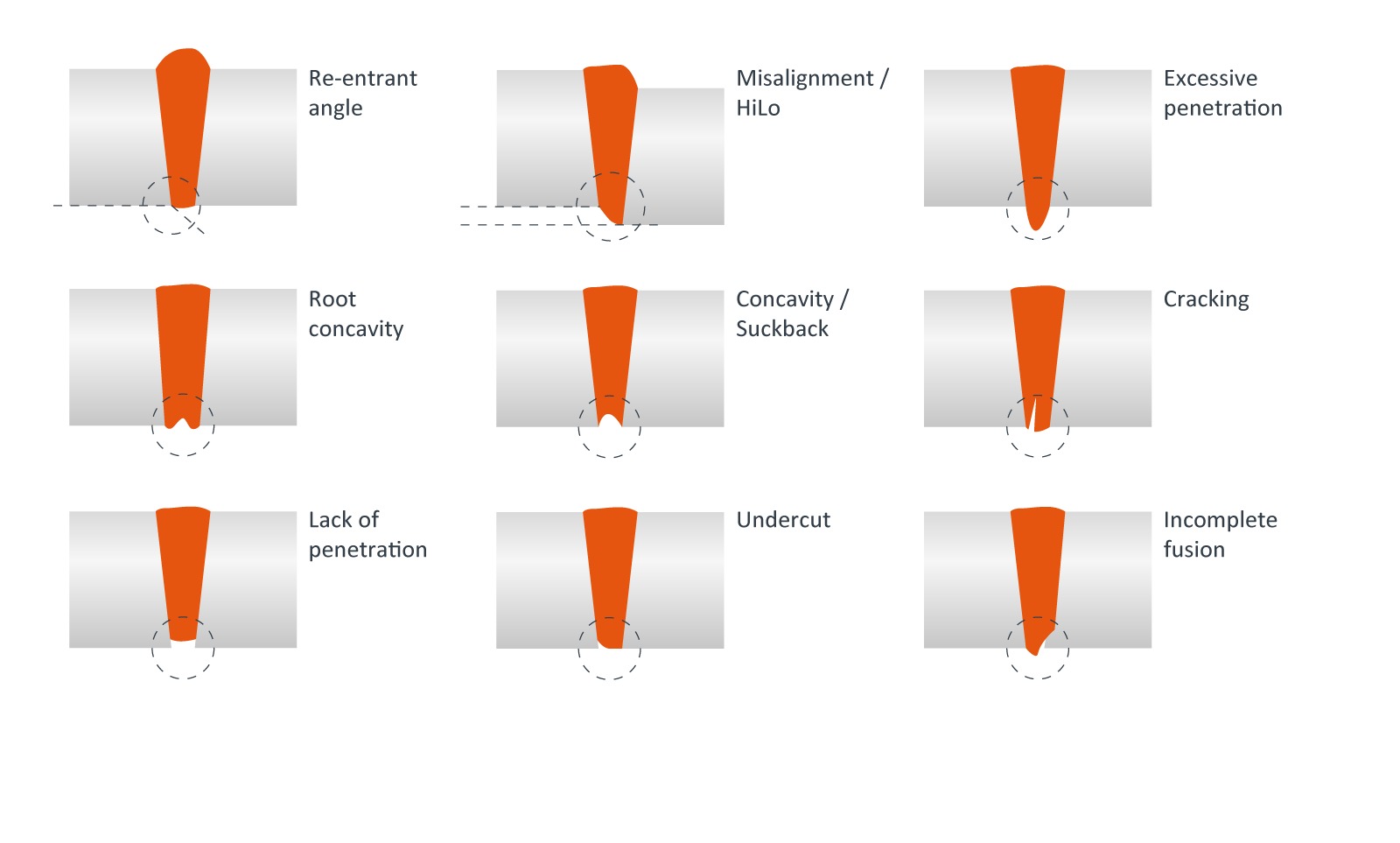

Most Common Welding Defects Oms Optical Metrology Services Ltd

Definition Of Welding Direction Variable Download Table

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Welding Closeup Industrial Worker At The Factory Welding Ad Industrial Closeup Welding Welding Factor Welding Art Welding And Fabrication Welding

Welding Joint Efficiency By Abdulrahman Al Rumaidh Linkedin

0 comments:

Post a Comment