Weld With Flat Face. It requires full penetration for laying strong welds.

1g 2g 3g 4g 5g 6g 1f 2f 3f 4f Pipe And Plate Welding Position Engineering Blog

The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses.

Welding g meaning. The dotted line indicates the weld side. - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. Welding is usually used on metals and thermoplastics but can also be used on wood.

The weld or the opposite surface is concave in nature. Fillet Weld F It is a welding method for combining two parts of metal vertically or slightly at an angle. The welding symbol fig.

It usually involves preparing the edge pieces to form one of the groove weld shapes like V bevel U J Flare V Flare bevel or no preparation at. The table presents some of the most commonly used welding symbols. Groove Weld G It is a weld made in the groove.

Fillet The most used weld. Basic welding positions are of 4 types which are Flat position Horizontal position Vertical position and overhead position. The near side or far side of the weld is a convex surface.

Weld With Convex Face. Welders must be certified in each position in order to perform those types of welds. Welding in a 3G position means moving the torch vertically up and down across a surface.

This is in contrast with 1G flat surface welding 2G horizontal welding and 4G overhead ceiling welding. That is why professional standard organizations such as ASME AWS ISO JWES make rules and classifications for welding positions. The welding symbol consists at least of a horizontal reference line has an arrow line pointing to the joint area and can have a tail with additional information for the welding process.

Groove Second most used. A distinction is made between the terms weld symbol and welding symbol. The weld symbol fig.

Arrow and Other Side Groove Weld Symbols. For fillet weld it is named as 1F 1 means the flat position and F means the fillet weld and for Groove weld it is named as 1G 1 means the Flat welding and G means the groove weld. One manufacturer could come out with a E71T-GS that uses shielding gas and another manufacturer could come out with one that does not use gas.

Weld With Concave Face. In untrained hands welding can be a safety hazard. The welding symbol describes the whole thing while the weld symbol can be part of the welding symbol.

3-3 indicates the desired type of weld. 3-2 is a method of representing the weld symbol on drawings. Welding is a fabrication or sculptural process that joins materials usually metals or thermoplastics by causing coalescence.

The symbol on the near and far side represent the type of weld surface. 1G 2G 5G and 6G. Arrow and Other Side Fillet Weld Symbols.

The weld symbol gives you information of the type of weld and is usually a part of the welding symbol. Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool. Welding is a permanent joint between two or more similar or dissilimar maraterials by heating them to a certain temperature with or without the application of pressure or by the pressure alone and with without adding filler materials.

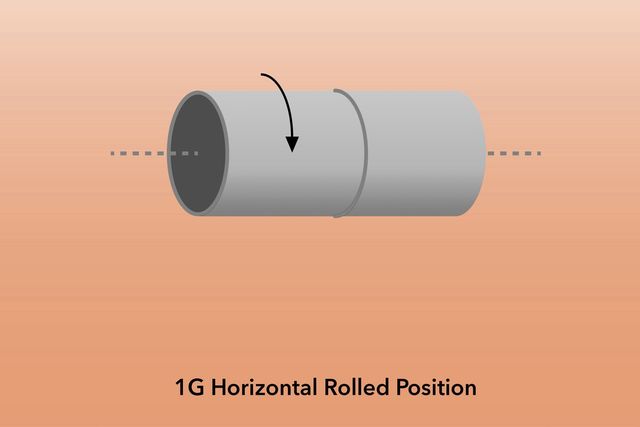

Pipe welding positions can be divided into 4 groups. 1G welding position is a position where the pipe is in a horizontal position and the pipe can be rotated against the horizontal axis or the X-axis. The welder conducts welding from the top of the pipe.

The completed welded joint may be. The G means that it has no other defined properties. This is the easiest welding position.

This element is used to pinpoint the exact location of the joint. Actually the way I understand it the S after the G indicates that is for single pass welding. The arrow segment contains the following.

The arrow is the part that specifies the location of welding at one end and connected to the reference line in the other.

1g 2g 3g 4g 5g 6g 1f 2f 3f 4f Pipe And Plate Welding Position Engineering Blog

Types Of Welding Positions Welder Portal

What Are The 1g 2g 5g And 6g Pipe Welding Positions

What Are The 1g 2g 5g And 6g Pipe Welding Positions

What Are The 1g 2g 5g And 6g Pipe Welding Positions

Types Of Welding Positions And 1g 2g 3g 4g 5g 6g 6gr Joint Types

Types Of Welding Positions Welder Portal

0 comments:

Post a Comment